Special single-handle two-jaw grasping forceps

A single handle, special technology, applied in the direction of clamps, manufacturing tools, etc., can solve the problem of not being found, and achieve the effect of avoiding slippage, convenient operation and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with accompanying drawing and embodiment:

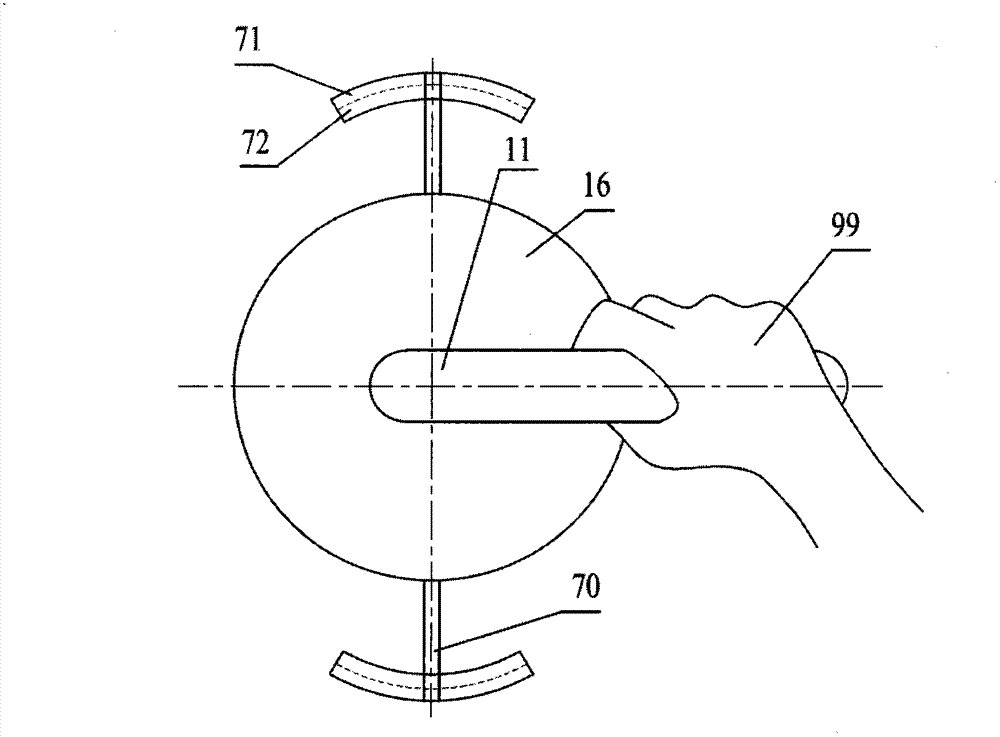

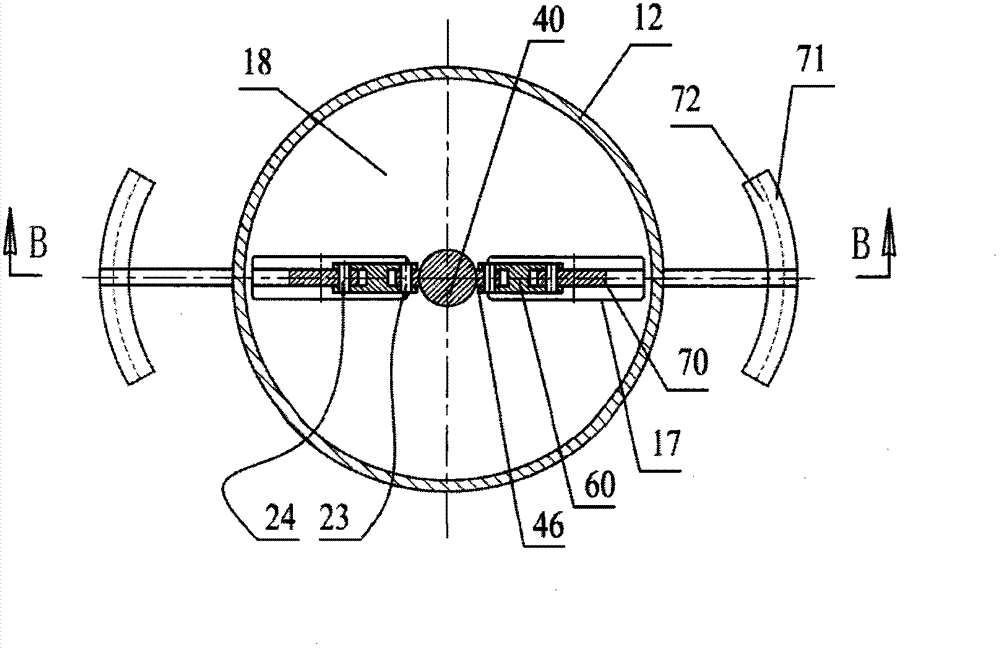

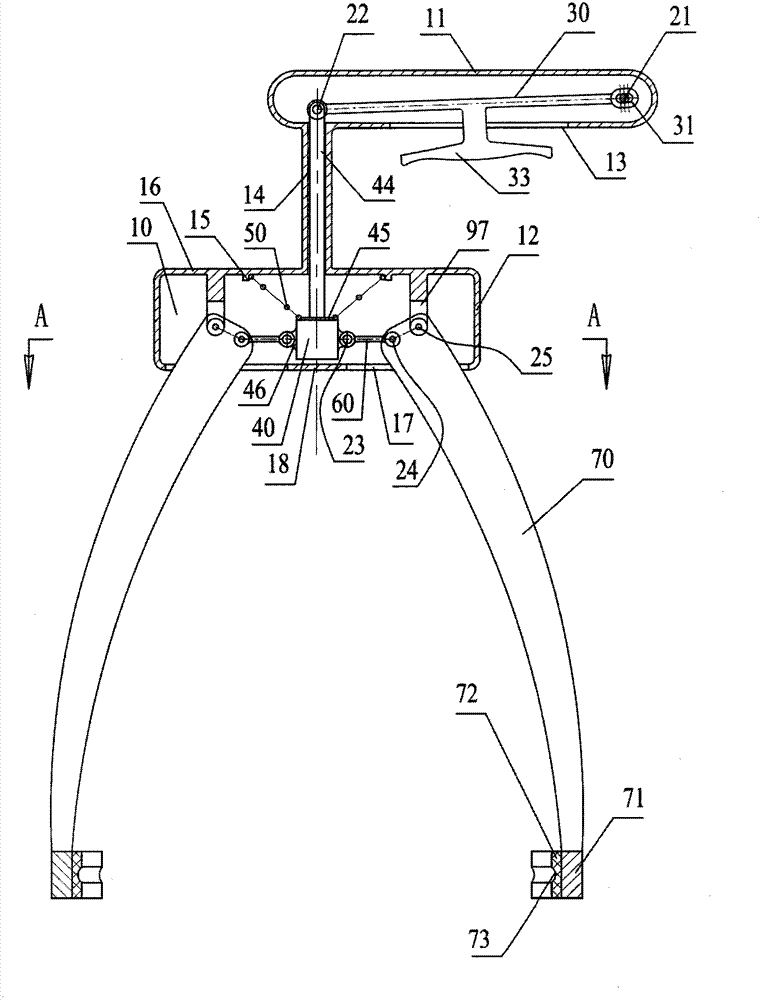

[0020] exist figure 2 , image 3 Among them, a single-handle special two-jaw clamping pliers, including a shell 10 and an operation control part, as an improvement: the hollow handle 11 of the shell 10 has a handle opening 13 below the middle part, and a pair of holes are formed on the inner surface of the outer end of the hollow handle 11. The boss hole 91, the hollow handle 11 is connected to the circular tube section 14 below the central axis, and the circular tube section 14 lower end is connected to the disc upper plane 16 of the control disc 12, and the inner surface of the disc upper plane 16 is provided with a spring upper fixed The circle 15 and the two suspension support feet 97 are arranged symmetrically on the outer side of the fixed circle 15 on the spring, and the disc lower plane 18 of the control disc 12 is also provided with two rectangular openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com