Fully-automatic battery replacement control system and method for electric vehicle

A technology for electric vehicles and control systems, applied in electric power units, power units, vehicle components, etc., can solve the problems of increasing labor intensity, the danger of battery replacement work, reducing the efficiency of battery replacement, and the weight of a single battery. The effect of security and stability, ease of management, and increased automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

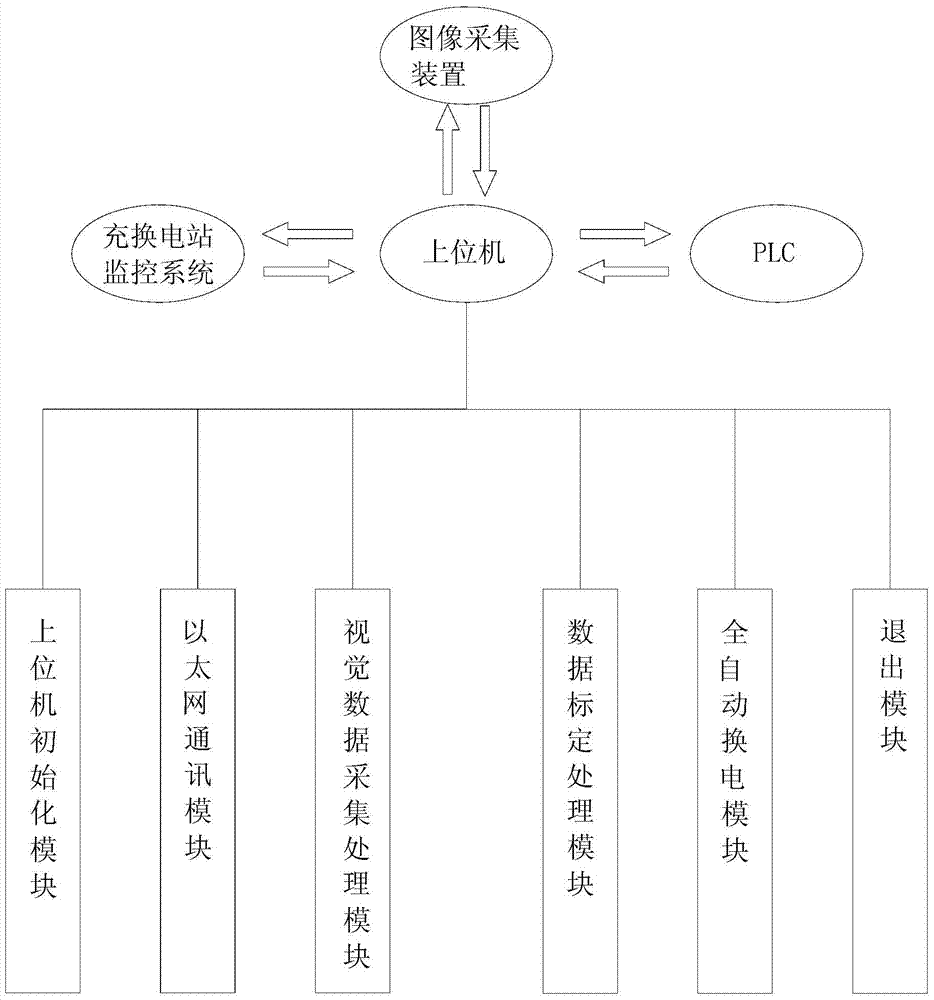

[0039] The following combination figure 1 The present invention is described in detail:

[0040] First, the electric vehicle fully automatic battery replacement control system of the present invention will be described. The system consists of three parts: upper computer, image acquisition device and PLC; the upper computer communicates with the image acquisition device and PLC respectively;

[0041] Among them, the image acquisition device is used to obtain the image information of the electric vehicle and the battery to be replaced when driving into the battery replacement station; the PLC is used to control the manipulator to complete the specific actions of battery replacement; The image information of the manipulator is converted into the position coordinate data and control commands of the manipulator in each process required by the PLC and sent to the PLC through the bus interface;

[0042] In particular, the fully automatic battery replacement control system for elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com