Installing structure of taper shank with attached cutting head

A technology of installation structure and cutting head, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inaccessible taper shank, unable to complete automatic installation of additional cutting heads, etc., to prevent loosening and improve processing efficiency. Effect

Inactive Publication Date: 2010-11-24

无锡桥联数控机床有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to overcome the above shortcomings, thereby providing a flexible connection between the taper shank and the additional cutting head, which solves the problem that the automatic installation of the additional cutting head cannot be completed when the taper shank is not at the same position as the rotation center line of the spindle taper surface At the same time, it also overcomes the situation that the taper shank cannot enter the positioning position after the pull nail is loosened. The additional cutting head taper shank installation structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

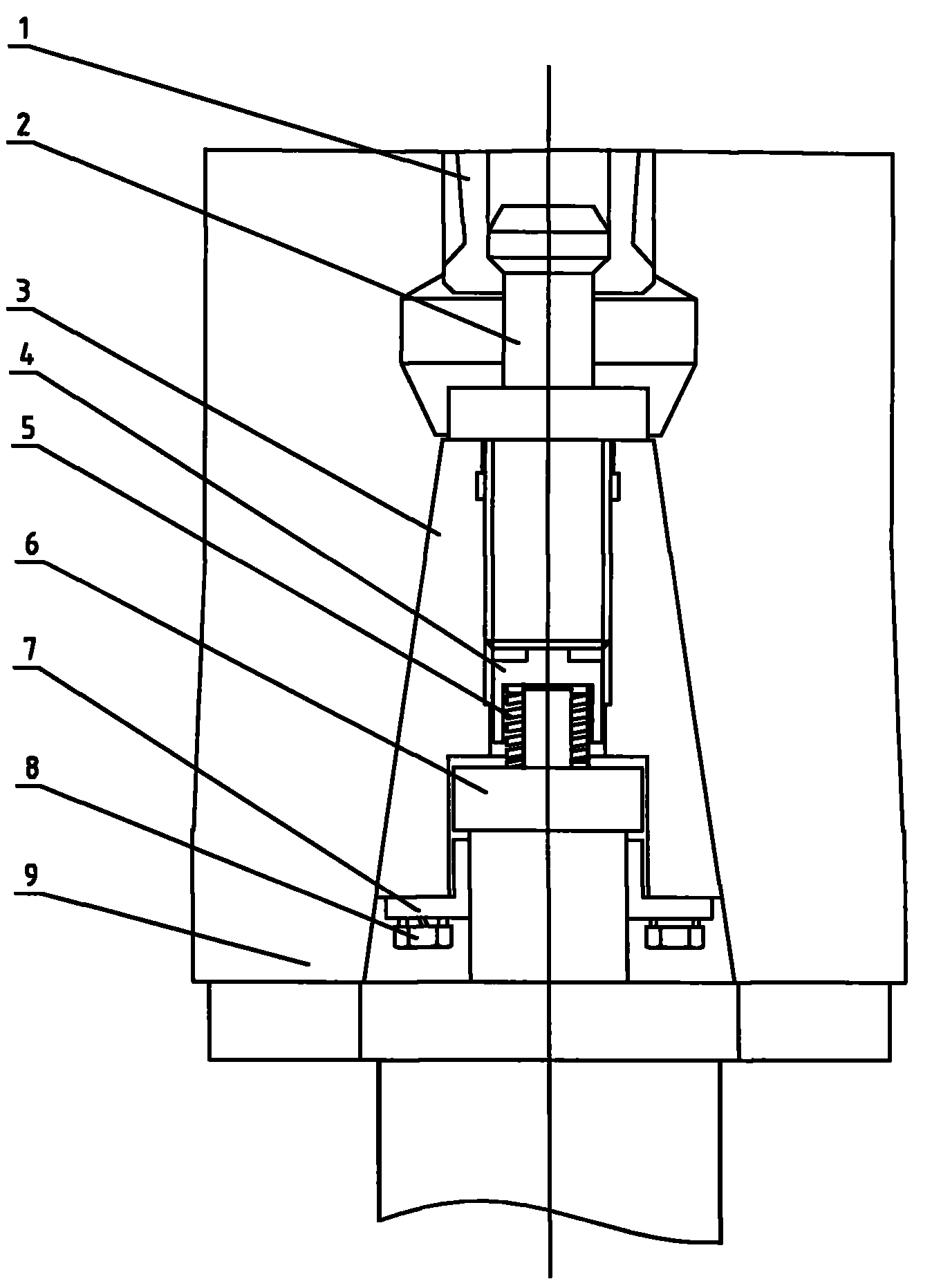

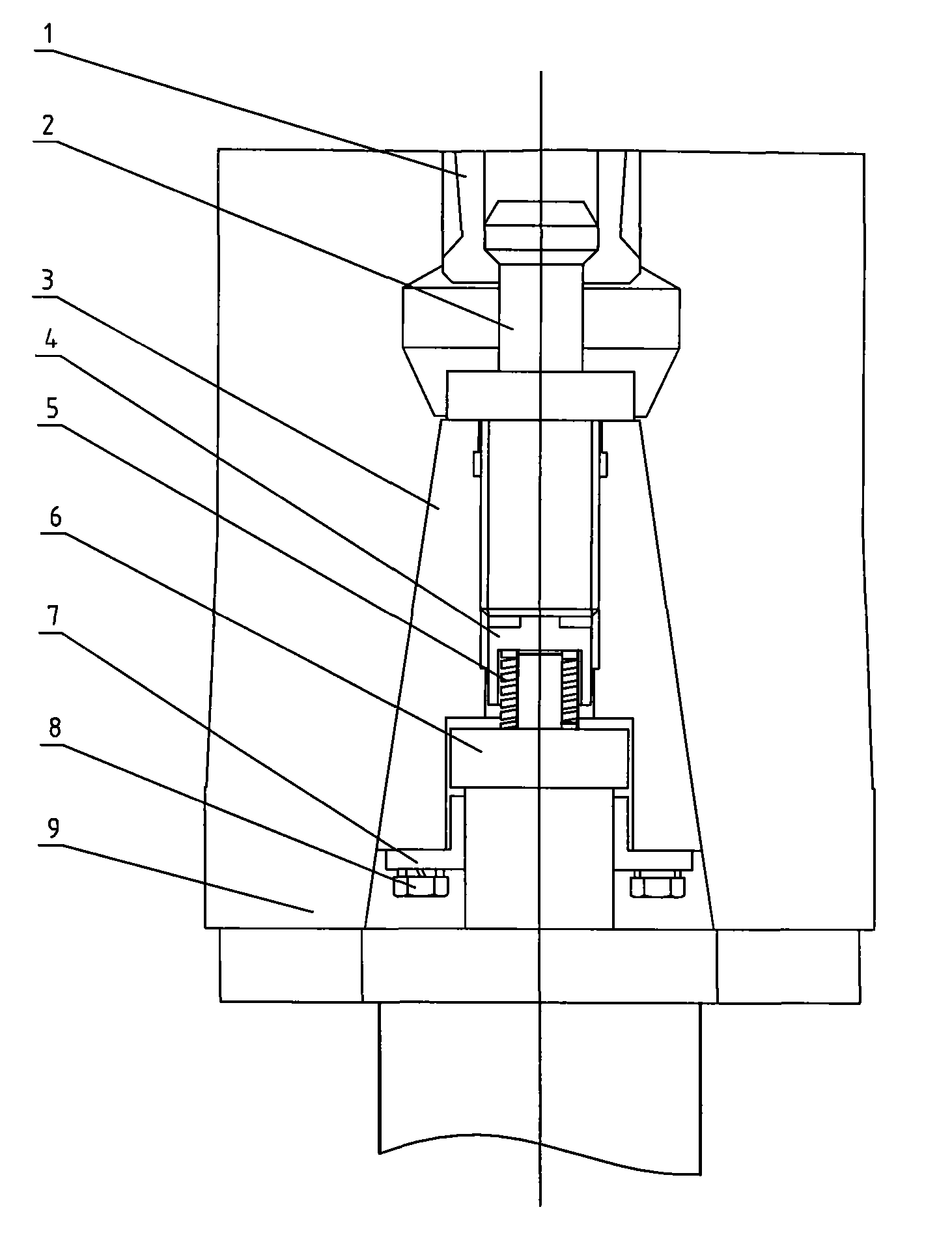

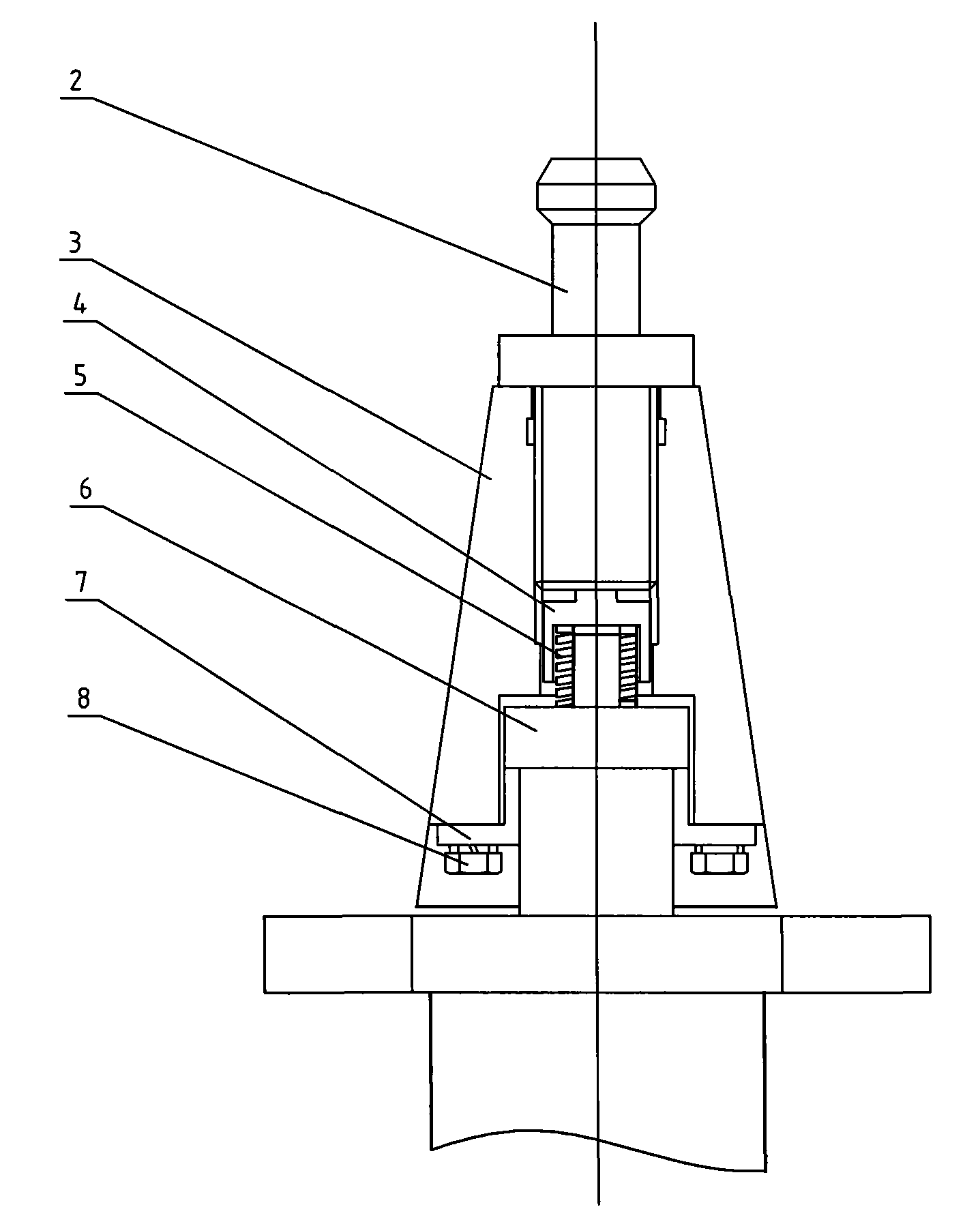

The invention relates to an installing structure of a taper shank with an attached cutting head, which is characterized in that: a press cover is fastened and connected at the lower end of the taper shank through a screw, a drive shaft is limited in a cavity formed by the press cover and the taper shank through a boss thereof, installation gap is formed at the connection and installation part of the taper shank and an auxiliary drive shaft; a spring is arranged on a short shaft at the upper end of the drive shaft, and a pull stud is connected with the taper shank through a thread. The installing structure can avoid the situation of shutdown after a sliding pillow of a main shaft receives greater resistance; meanwhile, the spring provides the elastic pre-tightening force for the thread connection part of the pull stud and the taper shank, thereby preventing the situation that a claw of the main shaft can not pull the attached cutting head to the installation position after the pull studis loose. The installing structure can not only reasonably solve the difficult automatic replacement of the cutting head caused by rigid connection of the taper shank, but also provide the pre-tightening force for the thread connection part, thereby preventing the looseness of the thread of the pull stud, protecting the smooth completion of the replacement action of the attached cutting head of afive-face gantry machining center and simultaneously improving the machining efficiency.

Description

An additional cutting head taper shank installation structure technical field The invention relates to an installation structure of an additional cutting head taper shank, in particular it is suitable for the installation of the additional cutting head taper shank and belongs to the technical field of mechanical structures. Background technique With the rapid development of my country's machinery industry, especially the development of heavy industry, there is an increasing demand for high-precision metal processing equipment such as pentahedron gantry machining centers. Pentahedron gantry machining centers are developed on the basis of gantry machining centers. A multi-functional CNC machine tool, through automatic replacement of various additional cutting heads, can realize multi-faceted processing of large mechanical parts. Usually, all or most of the processing procedures of large mechanical parts can be completed in one clamping, thus greatly reducing Improve production...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23Q3/157

Inventor 单文勇周晖黄俊桂周保牛强海华

Owner 无锡桥联数控机床有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com