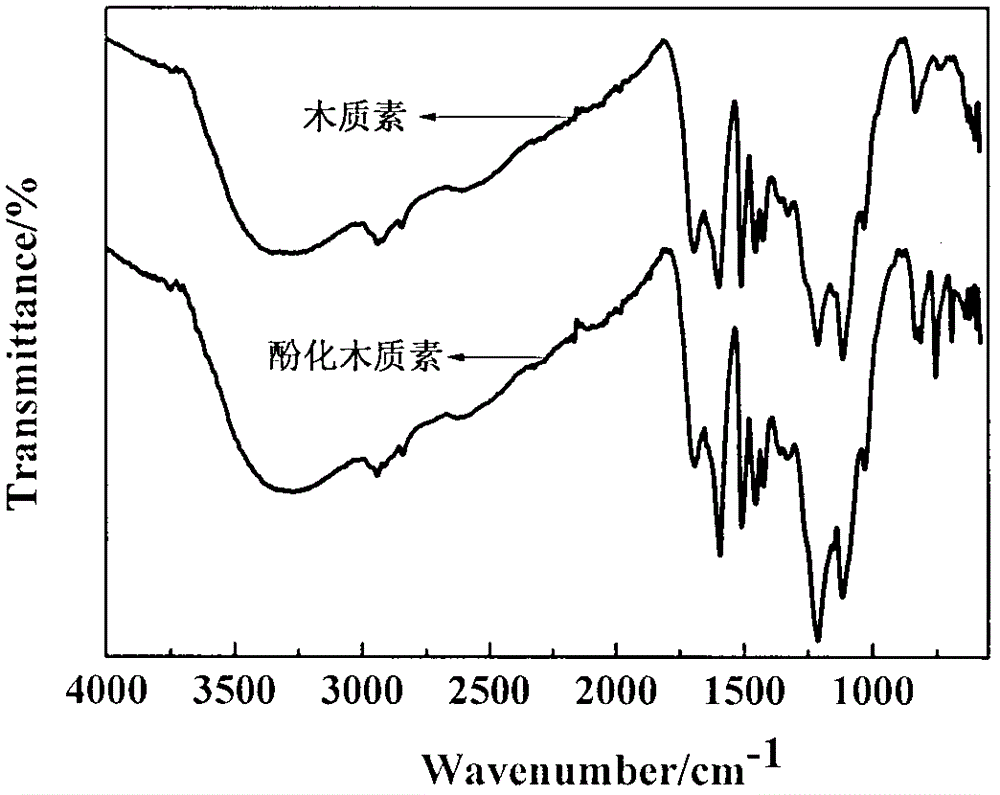

Phenolated lignin modified expandable resorcinol-phenol-formaldehyde resin and preparation method thereof

A technology of phenolizing lignin and resorcinol, which is applied in the field of preparation of lignin modified phenolic resin, can solve the problems of low foam strength, low lignin activity, high free formaldehyde of lignin phenolic resin, and achieve phenol replacement rate High, high mechanical strength, effect of promoting reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

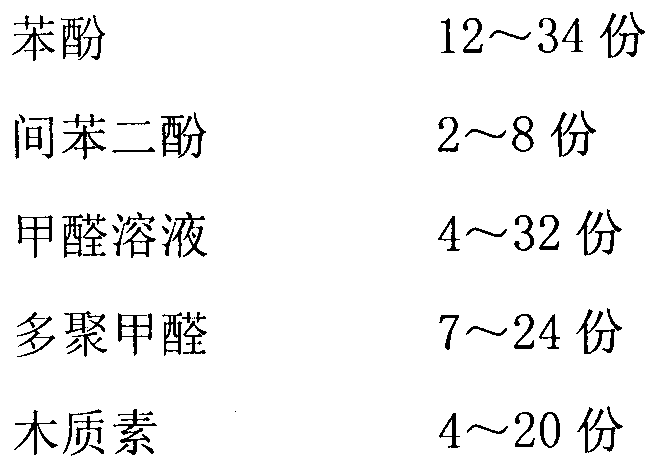

Embodiment 1

[0029] The first step, lignin phenolization degradation treatment: add 4 parts of enzymatic lignin, 34 parts of phenol, and 0.8 parts of 50% NaOH solution into the reactor, raise the temperature to 85°C, and react for 60 minutes; the second step, cool down to 75°C , add 32 parts of formaldehyde solution, carry out condensation polymerization reaction for 10 minutes; the third step, add 24 parts of paraformaldehyde in six times, add 0.8 parts of 50% NaOH solution in four times and react at 75°C for 60 minutes, wherein, the polyformaldehyde added each time The amount of formaldehyde is the same, and the amount of basic catalyst is also the same; in the fourth step, the temperature is lowered to 50° C., and 2 parts of resorcinol are added to react for 20 minutes. A resorcinol-phenol-formaldehyde resin modified by phenolized lignin is obtained.

[0030] See attached table 1 for the basic performance of the resin and the performance of its foam material.

Embodiment 2

[0032] The first step, lignin phenolization degradation treatment: add 20 parts of sodium lignosulfonate, 12 parts of phenol, and 5.6 parts of 50% NaOH solution into the reactor, raise the temperature to 100°C, and react for 240 minutes; the second step, cool down to 90 ℃, add 4 parts of formaldehyde solution, carry out condensation polymerization reaction for 40min; the third step, add 20 parts of paraformaldehyde in six times, add 2.4 parts of 50% NaOH solution in four times and react at 90℃ for 100min, wherein, each time adding more The amount of polyoxymethylene is the same, and the amount of basic catalyst is also the same; in the fourth step, the temperature is lowered to 60° C., and 8 parts of resorcinol are added to react for 100 minutes. A resorcinol-phenol-formaldehyde resin modified by phenolized lignin is obtained.

[0033] See attached table 1 for the basic performance of the resin and the performance of its foam material.

Embodiment 3

[0035] The first step, lignin phenolization degradation treatment: add 10 parts of calcium lignosulfonate, 24 parts of phenol, and 4.5 parts of 50% KOH solution into the reactor, raise the temperature to 90°C, and react for 180 minutes; the second step, cool down to 85 ℃, add 20 parts of formaldehyde solution, and carry out condensation polymerization for 30 minutes; the third step, add 16 parts of paraformaldehyde in six times, add 1.5 parts of 50% KOH in four times, and react at 90℃ for 70 minutes, wherein, the paraformaldehyde added each time The amount of formaldehyde is the same, and the amount of basic catalyst is also the same; in the fourth step, the temperature is lowered to 80° C., and 6 parts of resorcinol are added to react for 70 minutes. A resorcinol-phenol-formaldehyde resin modified by phenolized lignin is obtained.

[0036] See attached table 1 for the basic performance of the resin and the performance of its foam material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com