Stimulation reinforcer with high volume industrial waste residue powder used for concrete and its preparation method

A technology of industrial waste slag powder and large dosage, applied in cement production, etc., can solve the problems of poor excitation effect and adaptability, unsatisfactory application effect, low stability, etc., and achieve simple and reasonable production process, high cost performance and low product cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

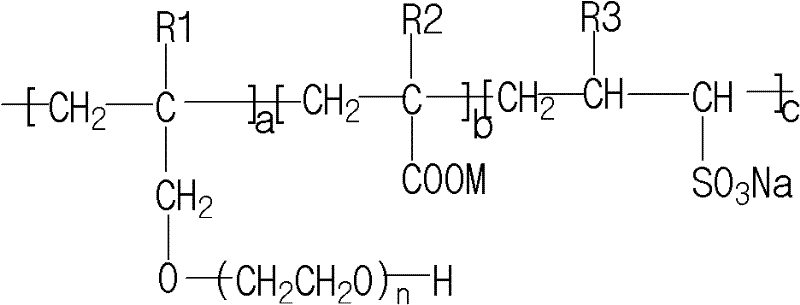

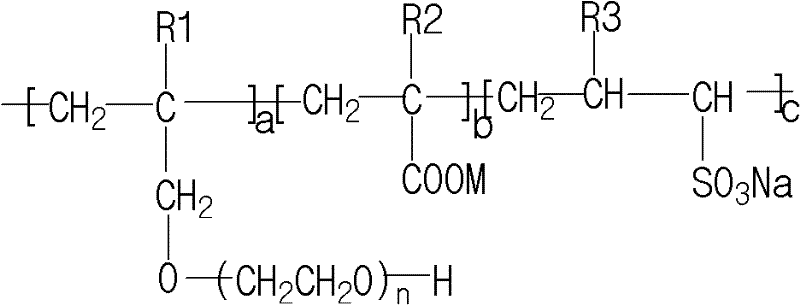

[0038] Preparation of dispersed excitation components:

[0039] Monomer A is:

[0040] Monomer B is:

[0041] Wherein monomer C is:

[0042] Where n=15, the molar ratio of monomers A, B and C is 1:3:0.5. According to the method disclosed in the patent US 7232873B2, excess alkali is added for neutralization to prepare polycarboxylate water reducer.

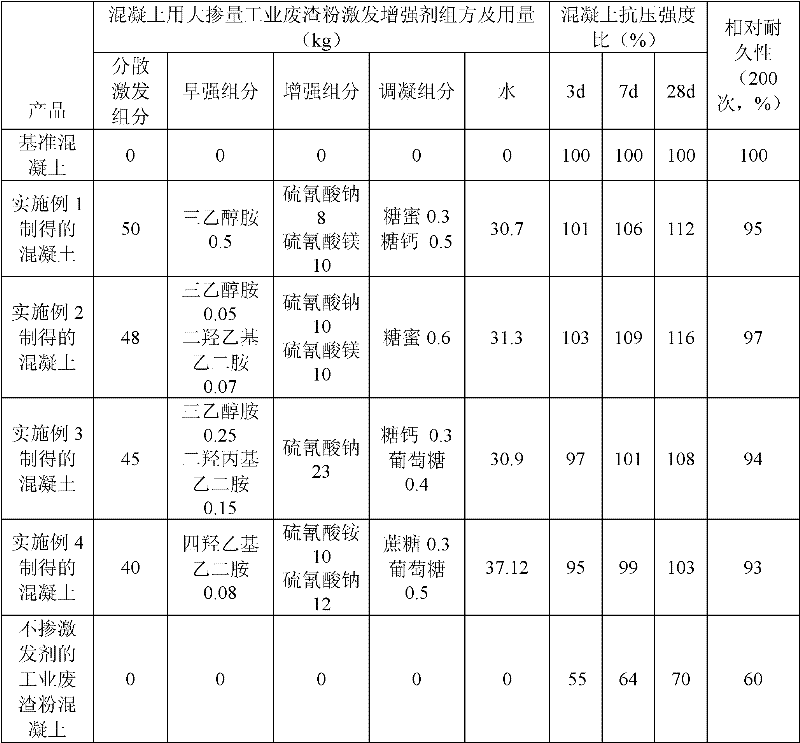

[0043] Preparation of large-volume industrial waste slag powder excitation enhancer for concrete: 30.7kg of water, 50kg of dispersed excitation components, 0.5kg of triethanolamine, 8kg of sodium thiocyanate, 10kg of magnesium thiocyanate, 0.3kg of molasses and 0.5kg of calcium sugar , Stir until it is completely dissolved, and the product is obtained.

[0044] Preparation of large-volume industrial waste powder concrete:

[0045] The mix ratio of large-volume industrial waste slag powder concrete is cement: mineral powder: fly ash: sand: gravel = 132:132:66:760:1120, and the water consumption is subject to the initial s...

Embodiment 2

[0048] Preparation of dispersed excitation components:

[0049] Monomer A is:

[0050] Wherein monomer B is:

[0051] Wherein monomer C is:

[0052] Where n=10, the molar ratio of monomers A, B and C is 1:4:1, according to the method disclosed in the patent US 7232873B2, the polycarboxylate water reducer is prepared by adding excess alkali for neutralization.

[0053]Preparation of large-volume industrial waste slag powder excitation enhancer for concrete: 31.3kg of water, 48kg of dispersed excitation component A, 0.05kg of triethanolamine, 0.07kg of dihydroxyethylethylenediamine, 10kg of sodium thiocyanate, and thiocyanate 10kg of magnesium and 0.6kg of molasses are stirred until they are all dissolved to obtain the product.

[0054] Preparation of large-volume industrial waste powder concrete:

[0055] The mix ratio of large-volume industrial waste slag powder concrete is cement: slag powder: fly ash: sand: gravel = 116:132:82:760:1120, and the water consumption is...

Embodiment 3

[0058] Preparation of dispersed excitation components:

[0059] Monomer A is:

[0060] Monomer B is:

[0061] Wherein monomer C is:

[0062] Where n=20, the molar ratio of monomers A, B and C is 1:5:0.6, according to the method disclosed in the patent US 7232873B2, the polycarboxylate water reducer is prepared by adding excess alkali for neutralization.

[0063] Preparation of large-volume industrial waste slag powder excitation enhancer for concrete: 30.9 kg of water, 45 kg of dispersed excitation component A, 0.25 kg of triethanolamine, 0.15 kg of dihydroxypropyl ethylenediamine, 23 kg of sodium thiocyanate, and 0.3 kg of calcium sugar kg and 0.4kg of glucose, stirred until all of them were dissolved to obtain the product.

[0064] Preparation of large-volume industrial waste powder concrete:

[0065] The mix ratio of large-volume industrial waste powder concrete is cement: slag powder: fly ash: sand: gravel = 99:132:99:760:1120, and the water consumption is subjec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com