Metal foam matrix filter system for removing hydrocarbons from exhaust air and method thereof

A metal foam and filter technology, applied in chemical instruments and methods, separation methods, electronic control of exhaust gas treatment devices, etc., can solve the problems of high energy and cost of thermal exhaust gas purification devices, and achieve rapid and uniform temperature rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

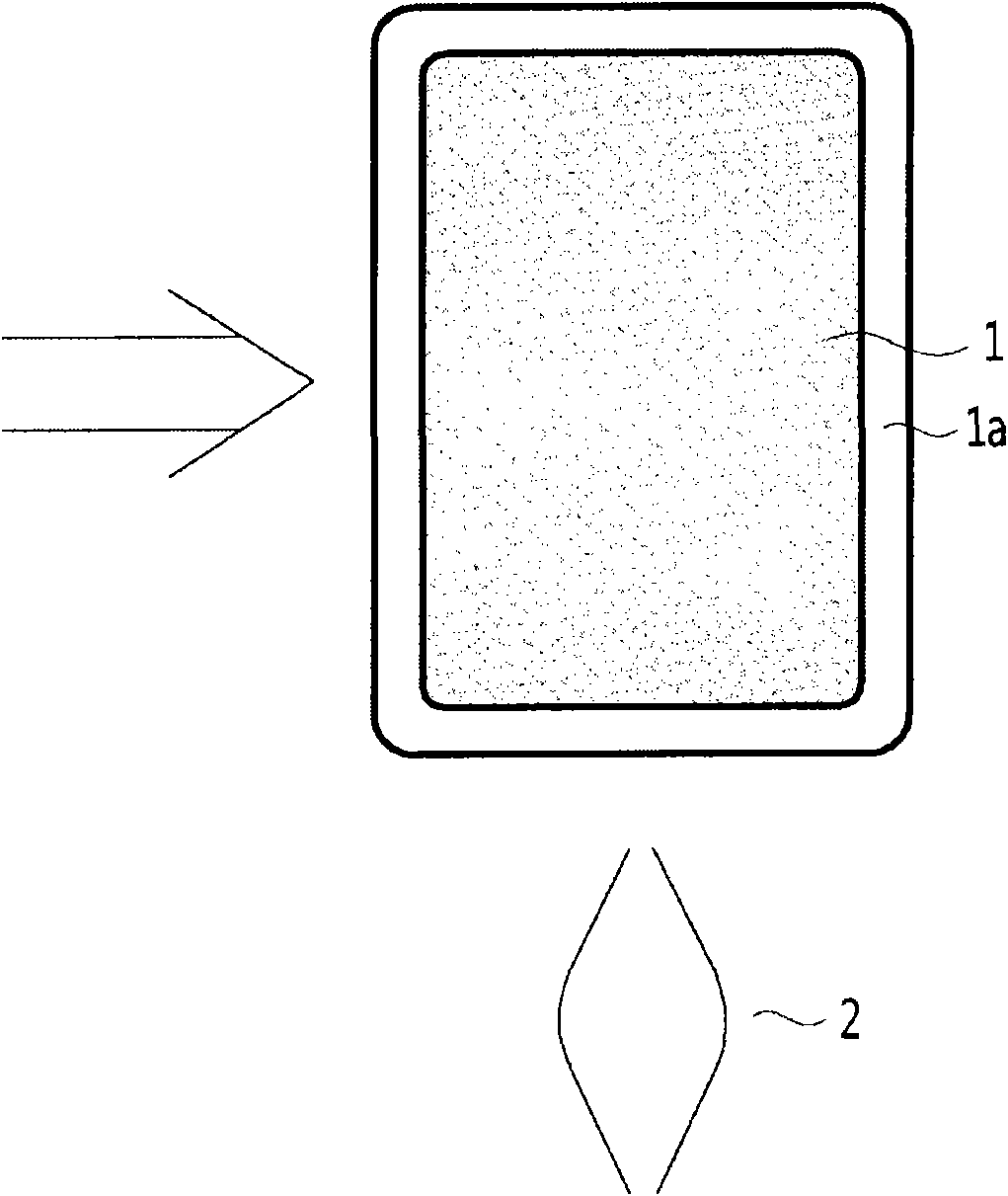

[0033] as in figure 1 As can be seen in , a filter system for removing hydrocarbons from exhaust gases and which can be used, for example, to purify exhaust gases in painted rooms or the like comprises a metal foam element 1 consisting of a foamed porous metal or a foamed porous metal alloy. Although in the figure the pores are represented by closed circles, it is clear to the person skilled in the art that the metal foam element 1 must contain at least some open pores to allow the exhaust gas to be purified (indicated here by the arrow on the left side of the metal foam element 1 ) through. At least one component of the metal or metal alloy is an element that acts as a catalyst for the oxidation of hydrocarbons. Suitable catalysts may for example comprise one or more elements selected from the group consisting of iron (Fe), nickel (Ni), silver (Ag), platinum (Pt), palladium (Pd).

[0034] A zeolite coating 1a is applied to the metal foam element 1 . More precisely, the zeo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com