A kind of flask heating support

A technology for flasks and support rods, applied to laboratory appliances, supporting appliances, chemical instruments and methods, etc., can solve the problems of uneven heating, poor thermal insulation performance, uncleanness, etc., and achieve reasonable and novel structural design, fast heating and Uniform, reduce heat consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

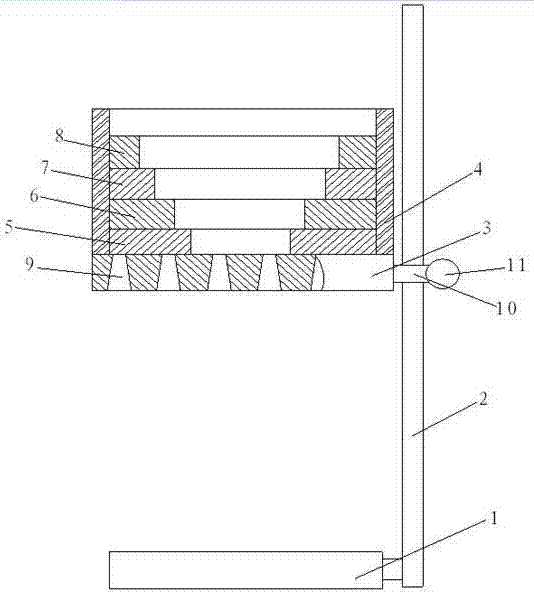

[0010] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

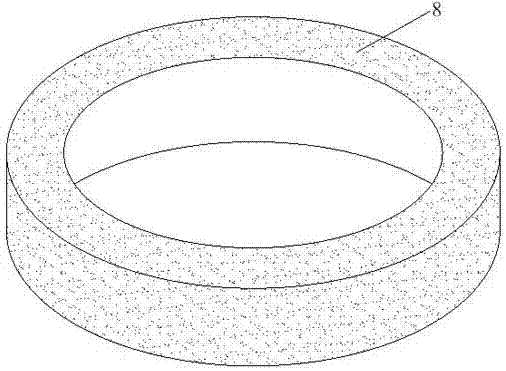

[0011] The invention relates to a flask heating bracket, which includes a base, and a support rod is arranged on the side of the base, and the support rod is vertically arranged on the upper surface of the base; There is a cylindrical cavity in the disc, and the spacer I, spacer II, spacer III and spacer IV are arranged in the cavity, and the spacer I, spacer II, spacer III and spacer IV are all Ring block, the outer edge radius of block I, block II, block III and block IV is the same, the inner edge radius of block II is 1.27 times the radius of the inner edge of block I, and the inner edge radius of block III The radius is 1.56 times the radius of the inner edge of block I, the radius of the inner edge of block IV is 1.97 times the radius of the inner edge of block I; the height of the side surface of block II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com