Method and device for preparing polyurethane water-resistant paint by microwave reaction

A polyurethane waterproof and microwave reaction technology, which is applied in polyurea/polyurethane coatings, chemical instruments and methods, chemical/physical/physicochemical fixed reactors, etc., can solve high energy consumption, unstable product quality, and long synthesis time and other problems, to achieve the effect of synchronous heating, fast and uniform heating, and avoiding temperature inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

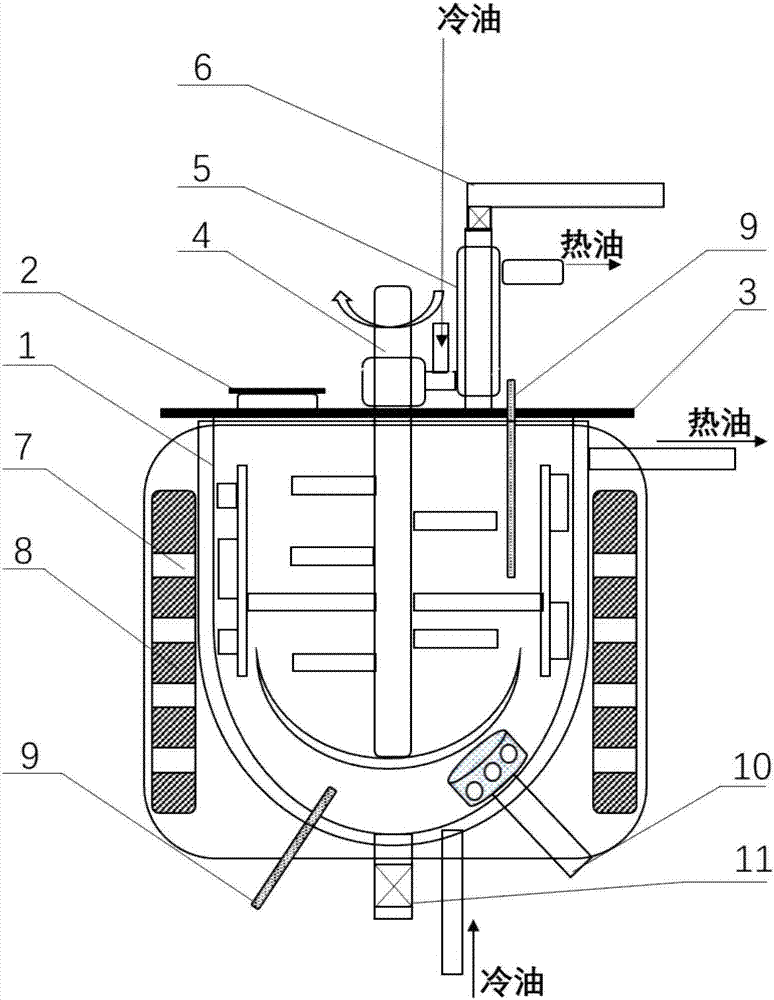

[0030] The microwave reaction of the present embodiment prepares the method for polyurethane waterproof coating, comprises the following steps:

[0031] In the microwave reactor, add 20 parts of polyether polyol 2000, 12 parts of polyether polyol 3000, and 0.1 part of dispersant through the vacuum feeding device in sequence, turn on the anchor stirring device and microwave heating device, raise the temperature to 60 ° C, and add 30 parts For pigments and fillers, turn on the high-speed shearing device, continue to heat up to 90°C, turn on the vacuum device, continue to heat up to 120°C, extract the condensate from the condenser device at the inlet end of the vacuum device, and use a moisture analyzer to detect the moisture content in the condensate until No moisture is detected, which means that the dehydration is completed, and the vacuum device and microwave heating device are stopped. Turn on the rapid cooling device, lower the temperature of the material to 60°C, feed 9 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com