Full-automatic equipment for high-flux hydrothermal synthesis and surface treatment

A technology of hydrothermal synthesis and surface treatment, which is applied to pressure vessels used in chemical processes, chemical/physical processes, chemical/physical/physical-chemical processes, etc. uniformity, slow cooling speed, etc., to save time, ensure stability, and save waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

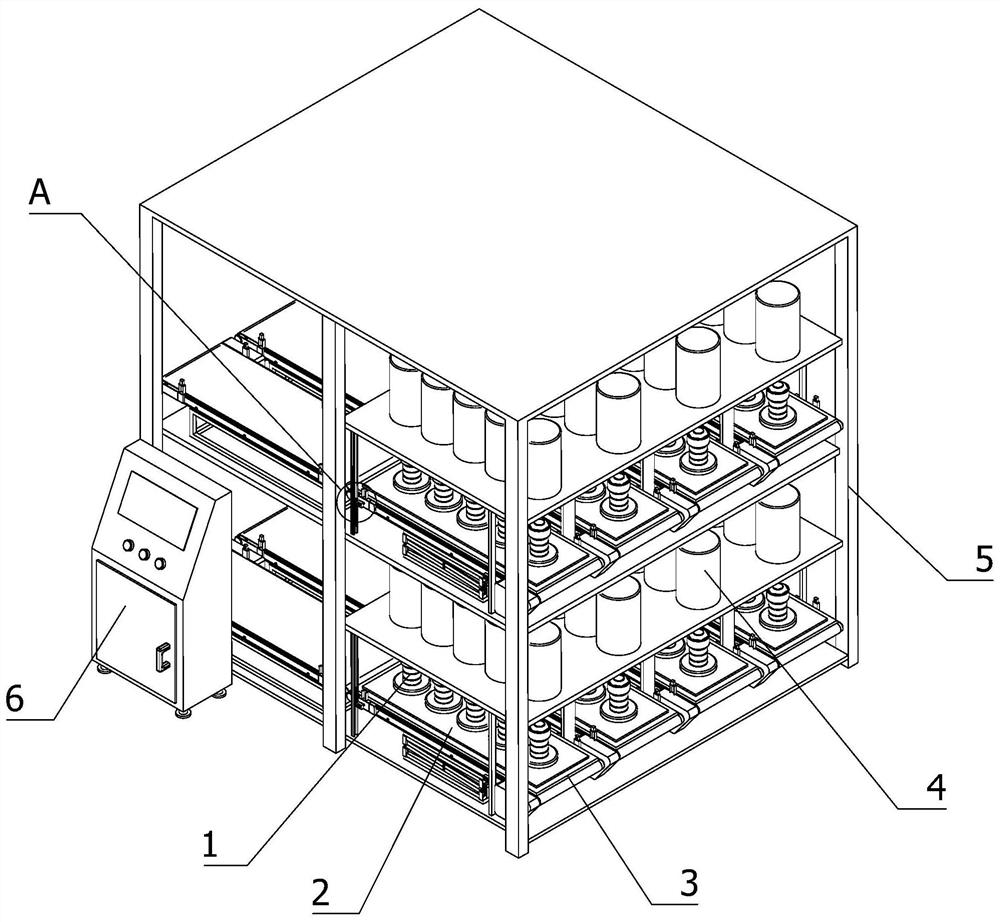

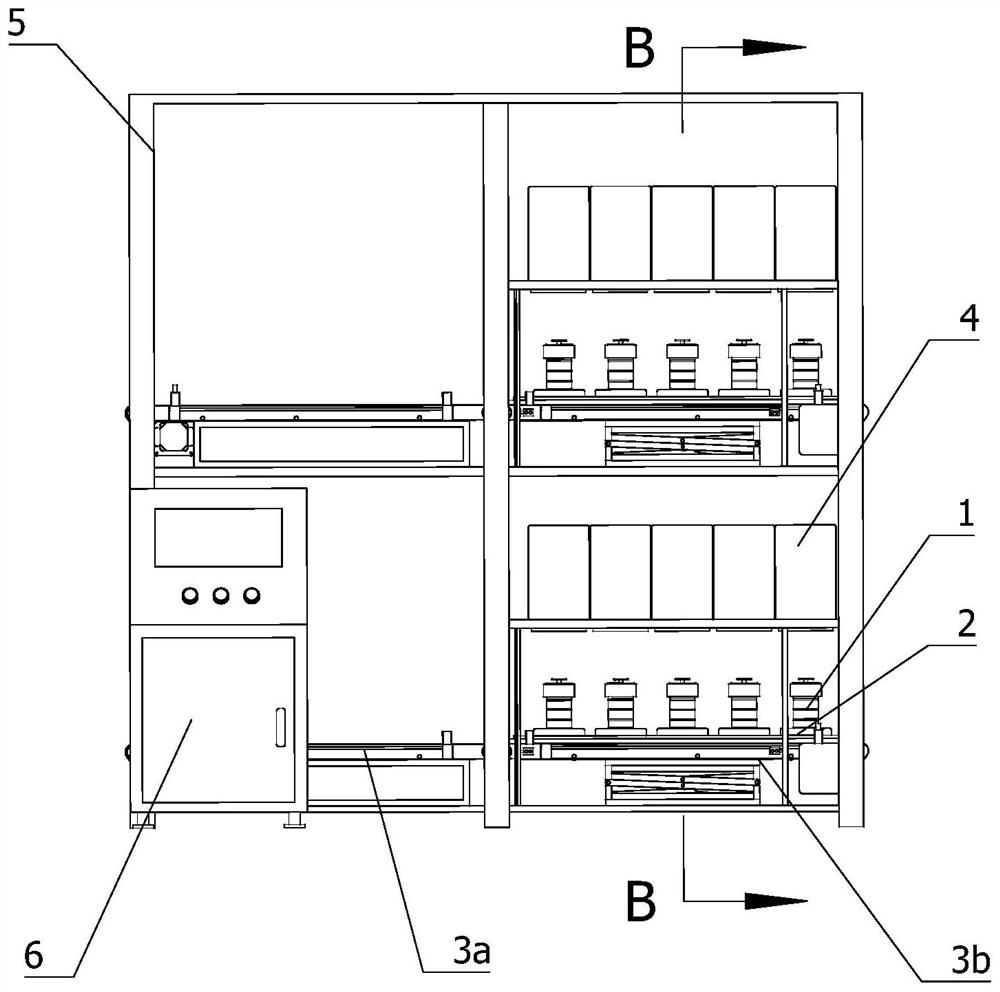

[0041] This embodiment proposes a fully automatic equipment for high-throughput hydrothermal synthesis and surface treatment, which is used for the experimental preparation of new material synthesis research and development. In a special sealed pressure reactor, a reaction system is heated to generate a Research on the preparation of different new materials synthesized by different formula components in a high temperature and high pressure environment.

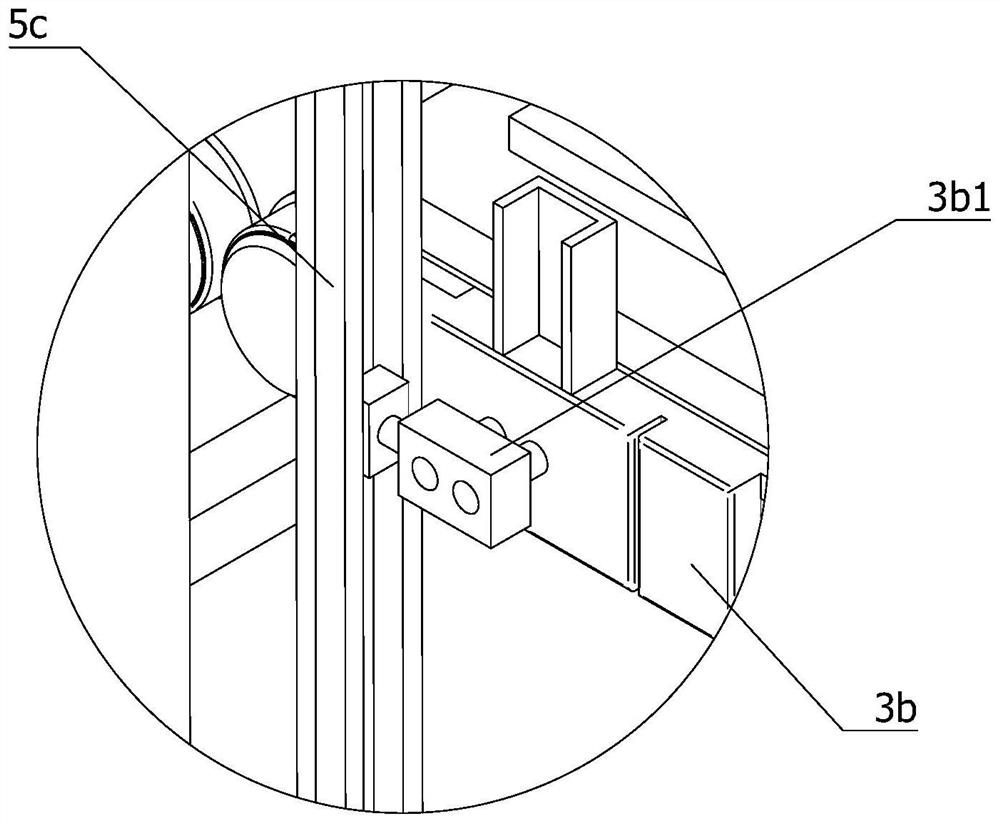

[0042] In order to solve the technical problem of how to automatically heat and cool multiple hydrothermal synthesis reactors independently, ensure that each hydrothermal synthesis reactor is placed in a uniform temperature field, and ensure the accuracy of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com