High-throughput hydrothermal synthesis and surface treatment device

A surface treatment device, hydrothermal synthesis technology, applied in chemical/physical processes, chemical/physical/physical chemical processes, chemical instruments and methods, etc., can solve the problem of slow cooling speed, inability to ensure the accuracy of temperature control, and difficult to meet The uniformity of the heating of the reactor and other issues can be achieved to save time, reduce the impact, and evenly heat the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

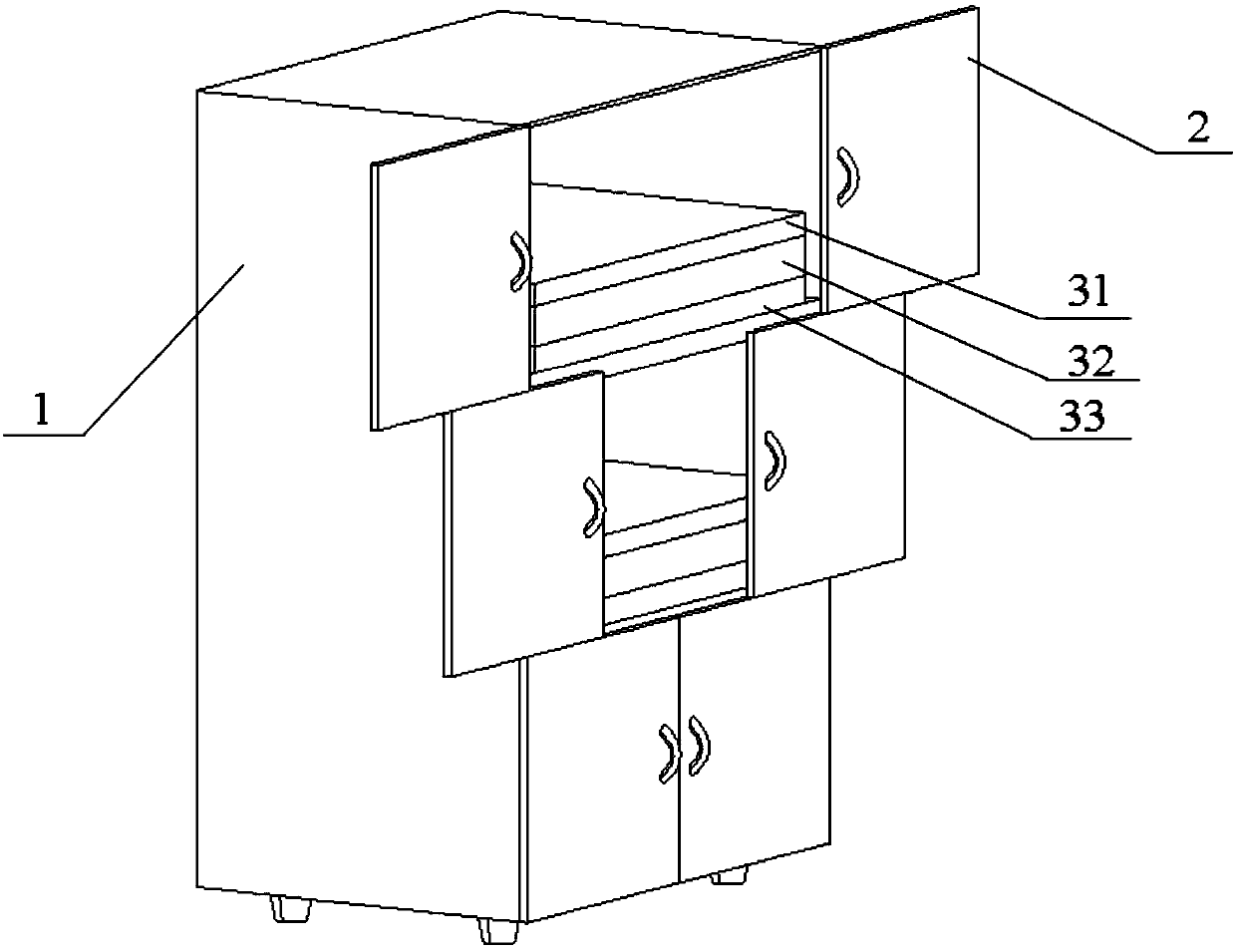

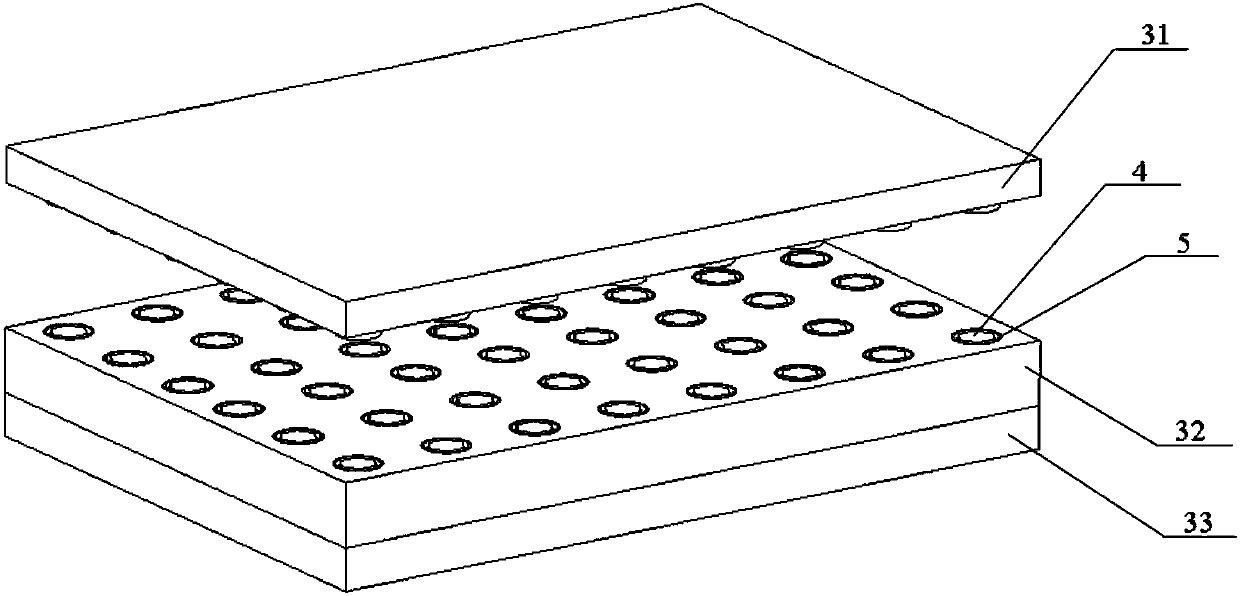

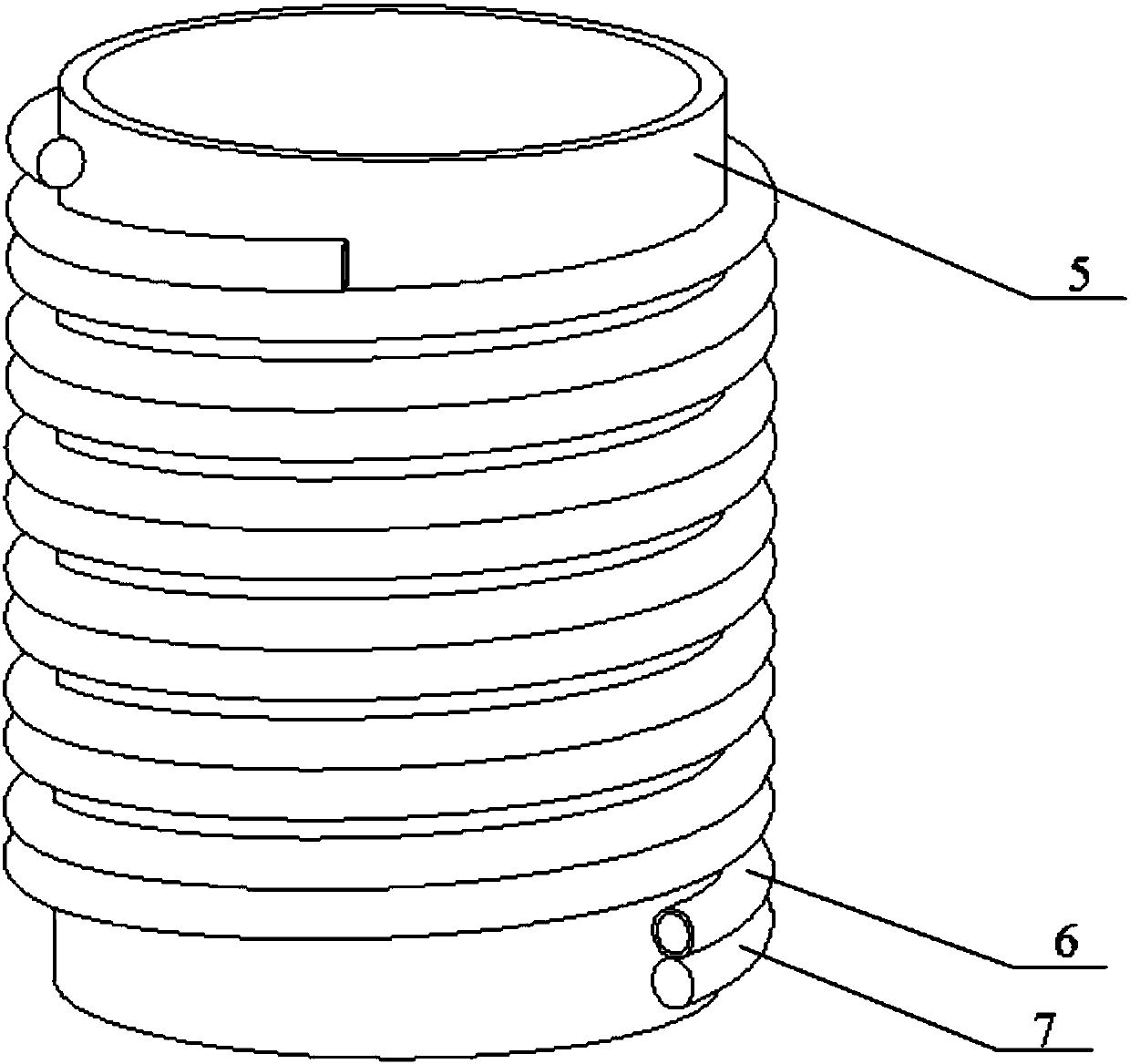

[0022] Such as Figure 1-3 As shown, a high-throughput hydrothermal synthesis and surface treatment device includes a device body 1 and a heating and cooling treatment device 3 arranged in the device body 1; the heating and cooling treatment device 3 includes an upper cover 31, a bottom cover 33 and The heat insulation part 32 arranged between the upper cover 31 and the bottom cover 33; the heat insulation part 32 is provided with a plurality of heat conduction sleeves 5, and the heat conduction sleeve 5 is provided with a hydrothermal reaction synthesis kettle 4; Cooling water pipes 6 and electric furnace wires 7 are wound on the surface; both cooling water pipes 6 and electric furnace wires 7 are connected to a temperature control device.

[0023] Further, the device body 1 is a box structure, and is provided with a box door 2 .

[0024] Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com