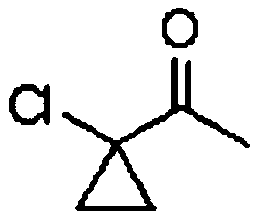

Method for preparing 1-(1-chlorocyclopropyl)ethanone by using micro-channel reactor

A micro-channel reactor and channel reactor technology, which are applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, carbon-based compound preparation, etc. and other problems, to achieve the effect of improving the conversion rate of raw materials and product yield, reducing the generation of by-products, and reducing the incidence of tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

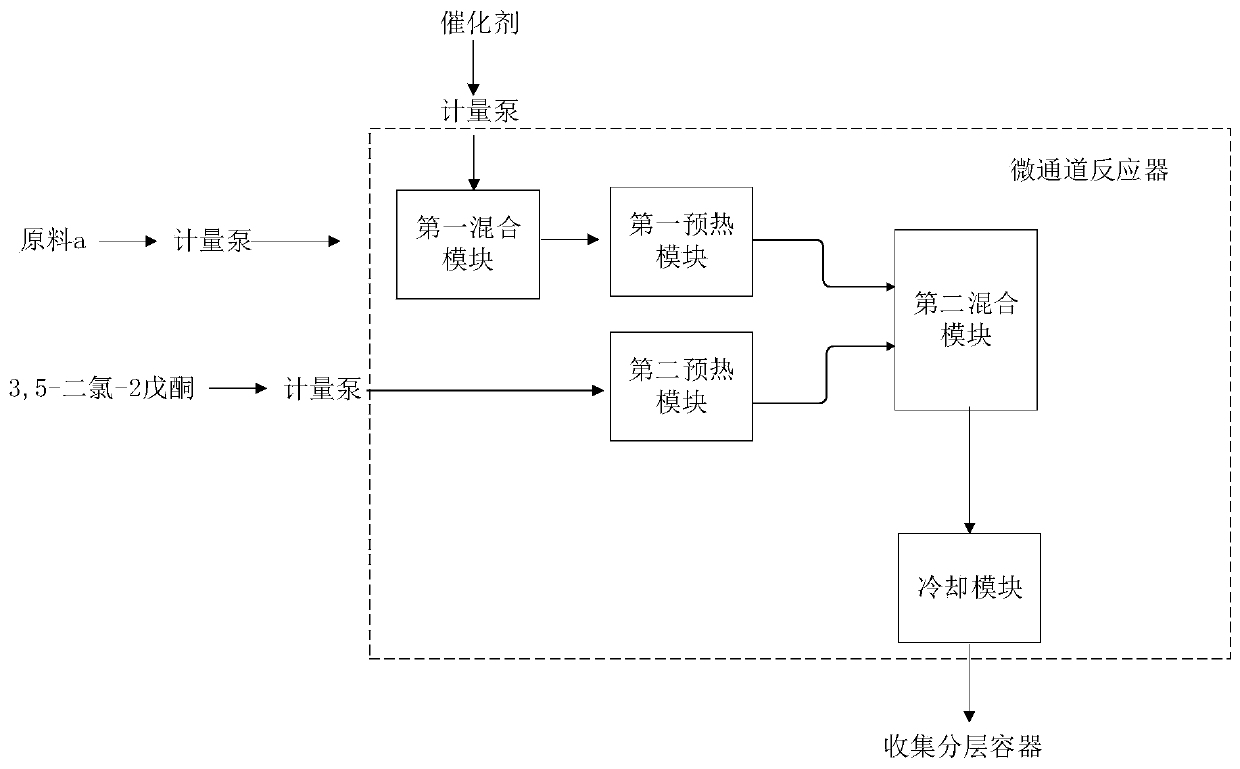

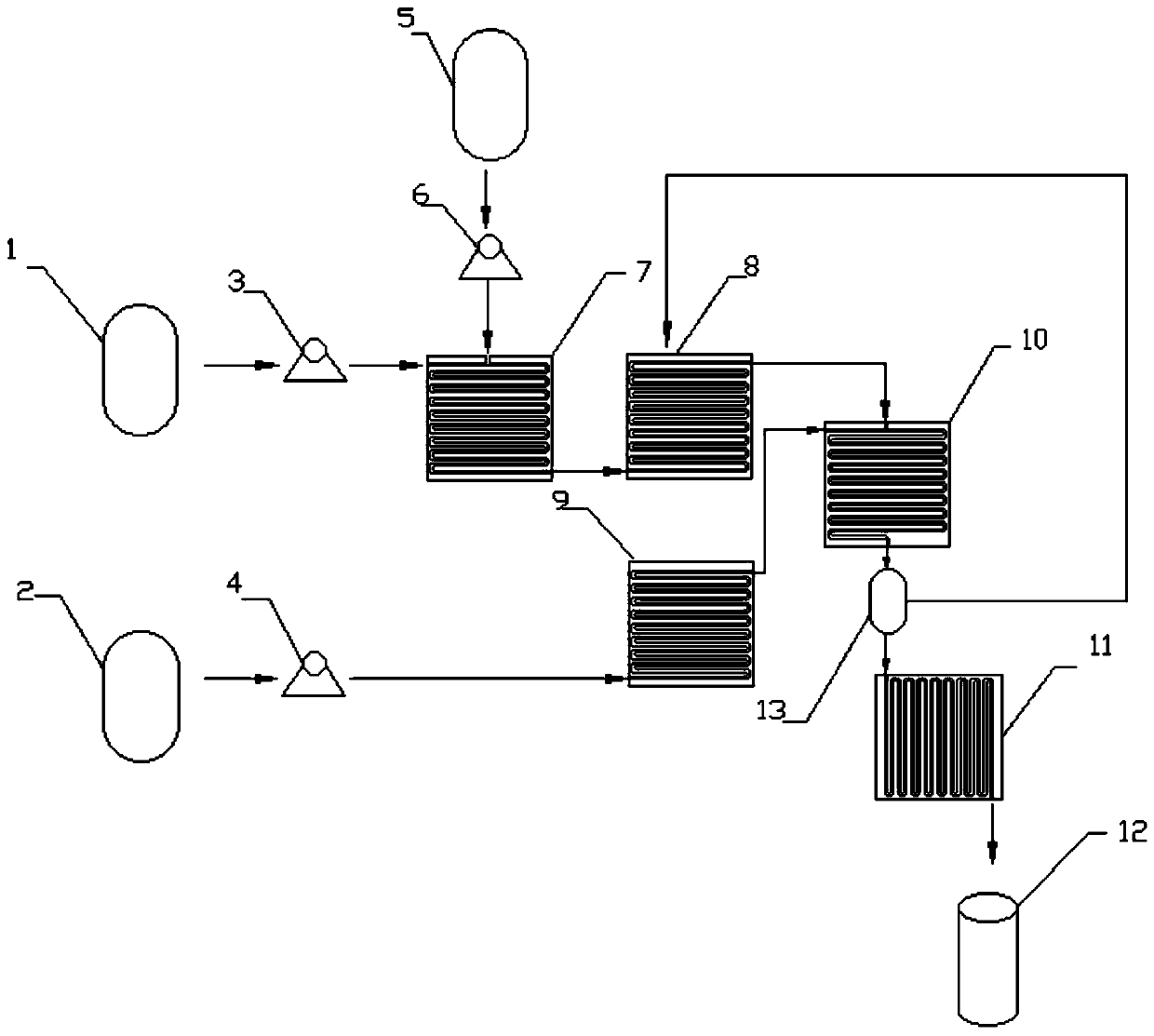

[0049] Such as figure 2 Shown, control metering pump 3,6 so that 20% liquid caustic soda is with the flow rate of 1kg / h, catalyst tetra-n-butylammonium bromide is with 0.25m 3 The flow velocity of / h enters the first mixing module 7 of microchannel reactor, and the mixing time of the first mixing module 7 is set as 1 minute, enters the first preheating module 8 after mixing 1 minute, the setting of the first preheating module 8 The fixed temperature is 70°C, and the preheating time is 2 minutes; the metering pump 4 is controlled so that 3,5-dichloro-2-pentanone enters the second preheating module 9 at a flow rate of 2.2kg / h, and the second preheating module 9 The set temperature is 70°C, and the preheating time is 2 minutes; after 2 minutes of preheating, the mixture of 20% and catalyst and 3,5-dichloro-2-pentanone are simultaneously passed into the second mixing module 10 for cyclic For the cyclization reaction, the set temperature of the second mixing module 10 is 70° C., ...

Embodiment 2

[0051] Such as figure 2 Shown, control metering pump 3,6 so that 20% liquid caustic soda is with the flow rate of 1kg / h, catalyst tetra-n-butylammonium bromide is with 0.25m 3 The flow velocity of / h enters the first mixing module 7 of microchannel reactor, and the mixing time of the first mixing module 7 is set as 3 minutes, enters the first preheating module 8 after mixing 3 minutes, the setting of the first preheating module 8 The fixed temperature is 70°C, and the preheating time is 5 minutes; the metering pump 4 is controlled so that 3,5-dichloro-2-pentanone enters the second preheating module 9 at a flow rate of 2.2kg / h, and the second preheating module 9 The set temperature is 70°C, and the preheating time is 5 minutes; after 5 minutes of preheating, the mixture of 20% and the catalyst and 3,5-dichloro-2-pentanone are simultaneously passed into the second mixing module 10 for cyclic cyclization reaction, the temperature of the second mixing module 10 is set at 70°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com