Method for rapid synthesis of multi-element layered positive material of lithium-ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as difficult to accurately control the operation process, difficult to industrialize production, complex synthesis process, etc., to reduce energy consumption and improve material performance , the effect of rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

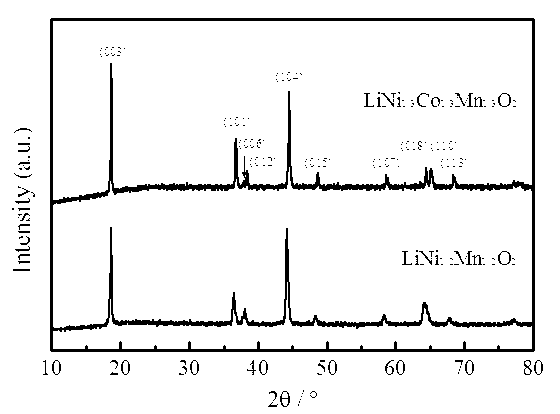

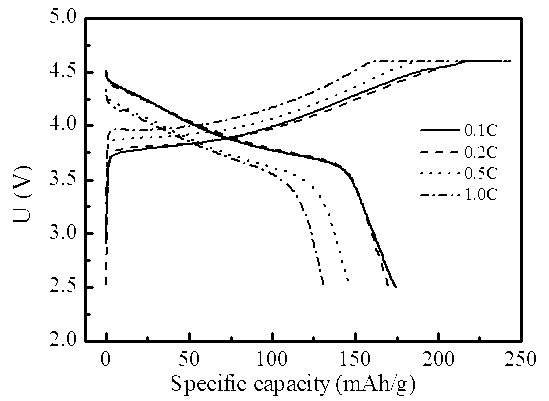

[0018] Rapid synthesis of binary layered cathode material LiNi for lithium ion batteries using lithium acetate, nickel nitrate and manganese acetate as raw materials 1 / 2 mn 1 / 2 o 2 .

[0019] (1) According to n(Li):n(Ni):n(Mn) (molar ratio) = 1.1:0.5:0.5, accurately weigh lithium acetate, nickel nitrate and manganese acetate, and put them into corundum crucibles.

[0020] (2) Heat the crucible containing the raw materials prepared in step (1) on an electric furnace to melt the raw materials to form a uniform liquid.

[0021] (3) Move the crucible containing the liquid obtained in step (2) into an electric furnace heated to 500°C and keep the temperature constant to make it burn.

[0022] (4) Collect the reaction product obtained in step (3), grind it, pass through a 100-mesh sieve, and press it into a disc under a pressure of 15 MPa with a tablet machine.

[0023] (5) Place the wafer obtained in step (4) in a microwave oven at 900°C for 120 minutes, and then cool in the ov...

Embodiment 2

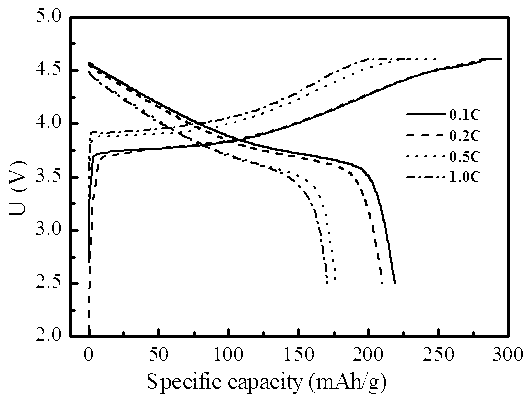

[0027] Rapid synthesis of ternary layered cathode material LiNi for lithium ion batteries from lithium acetate, nickel nitrate, cobalt nitrate and manganese acetate as raw materials 1 / 3 co 1 / 3 mn 1 / 3 o 2 .

[0028] (1) Accurately weigh lithium acetate, nickel nitrate, cobalt nitrate and manganese acetate according to n(Li):n(Ni):n(Co):n(Mn) (molar ratio)=1.1:0.33:0.33:0.33, into a corundum crucible.

[0029] (2) Heat the crucible containing the raw materials prepared in step (1) on an electric furnace to melt the raw materials to form a uniform liquid.

[0030] (3) Move the crucible containing the liquid obtained in step (2) into an electric furnace heated to 500°C and keep the temperature constant to make it burn.

[0031] (4) Collect the reaction product obtained in step (3), grind it, pass through a 100-mesh sieve, and press it into a disc under a pressure of 15 MPa with a tablet machine.

[0032] (5) Place the wafer obtained in step (4) in a microwave oven at 900°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com