Desalination and dehydration method and device of oily waste

A dewatering device and waste technology, applied in separation methods, grease/oily substance/float removal devices, mining wastewater treatment, etc., can solve the problems of desalination and dehydration easily affected by the properties of raw materials, short settling time, poor desalination effect, etc. , to achieve the effect of stable treatment effect, strong safety and compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

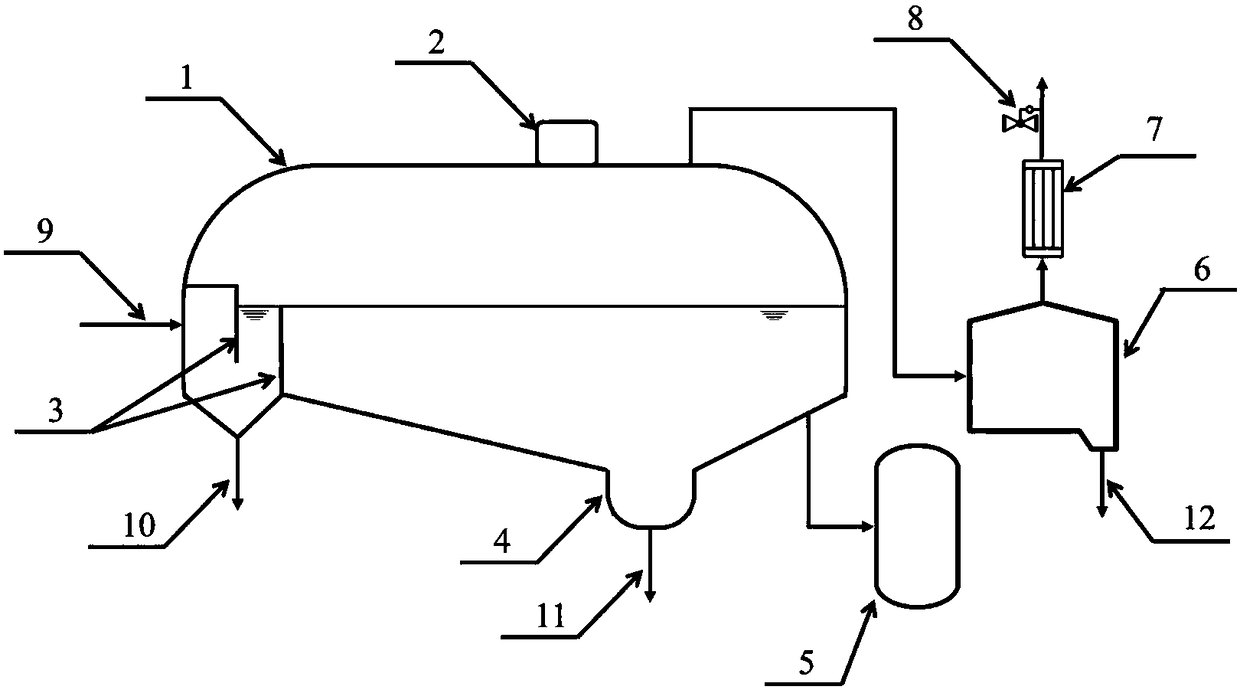

[0072] This example is used to illustrate the method for desalting and dehydrating oily waste of the present invention.

[0073] use figure 1 The shown device pumps dirty oil (water content is 37% by weight, salt content is 453mg NaCl / L, mechanical impurity is 3.3% by weight, and the balance is oil content) from inlet 9 to dehydration tank 1, through The U-shaped flow channel provided at the inlet 9 enters the main body of the dehydration tank 1, and then the pressure reducing valve 8 is closed to keep the dehydration tank 1 in a closed state, and the microwave reactor 2 is opened to carry out microwave heating to the dirty oil in the dehydration tank 1 ( The radiation frequency is 2450MHz, the power is 1200W), and when the temperature of the dirty oil is stabilized to 130°C, stop heating, and after the pressure in the dehydration tank is stabilized, the pressure relief valve 8 is opened to reduce the pressure in the dehydration tank 1 to normal pressure (approximately 101.3k...

Embodiment 2

[0076] This example is used to illustrate the method for desalting and dehydrating oily waste of the present invention.

[0077] According to the method described in embodiment 1, the difference is:

[0078] The treated oily waste is oil tank bottom sludge with a water content of 40.17% by weight, a salt content of 714mg NaCl / L, and mechanical impurities of 14.8% by weight;

[0079] The conditions of microwave heating include: the radiation frequency is 2450MHz, and the power is 1500W;

[0080] Microwave heating until the temperature of the oil sludge is 120°C, the condensed water collected in the light component reflux tank 6 after pressure relief accounts for 6% by weight of the water in the waste oil;

[0081] The moment the pressure is released, the temperature of the residual material in the dehydration tank 1 reaches 70° C., and it is kept at 70° C. for 30 minutes.

[0082] Wherein, the water content of the obtained purified oil was 0.9% by weight, and the dehydration ra...

Embodiment 3

[0084] This example is used to illustrate the method for desalting and dehydrating oily waste of the present invention.

[0085] According to the method described in embodiment 1, the difference is that microwave heating to the temperature of the dirty oil is 100° C., and the condensed water collected in the light component reflux tank 6 after pressure relief accounts for 2% by weight of the water in the dirty oil.

[0086] Thus, the water content of the obtained purified oil was 13.1% by weight, and the dehydration rate was 64.6%; the salt content was 194 mg NaCl / L, and the desalination rate was 57.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com