High-power carbon fiber electric heating plate, production process and application device

A carbon fiber, electric heating plate technology, applied in applications, home appliances, electronic equipment, etc., can solve the problem of low power, and achieve the effects of high power, simple manufacturing, and rapid temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

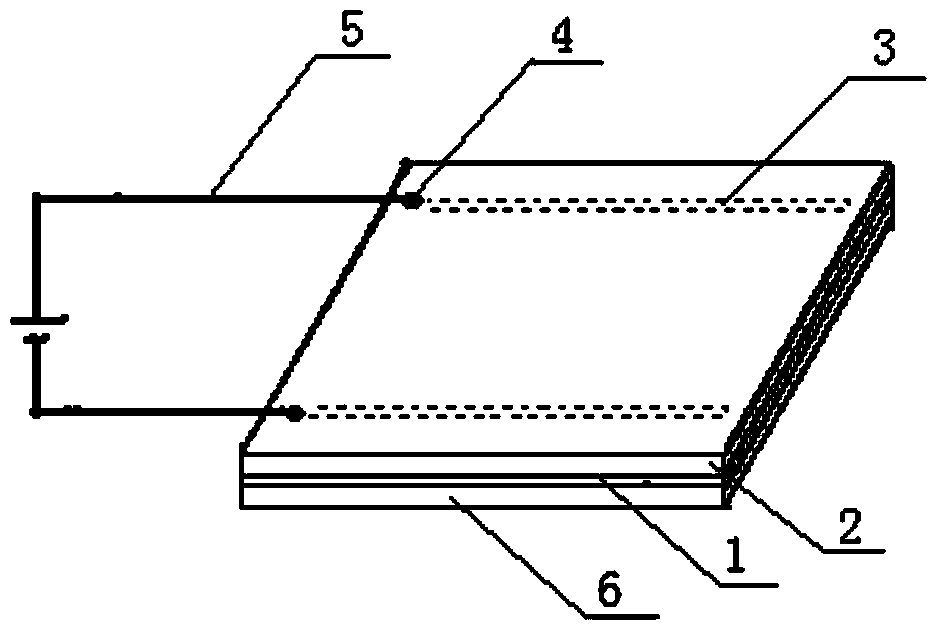

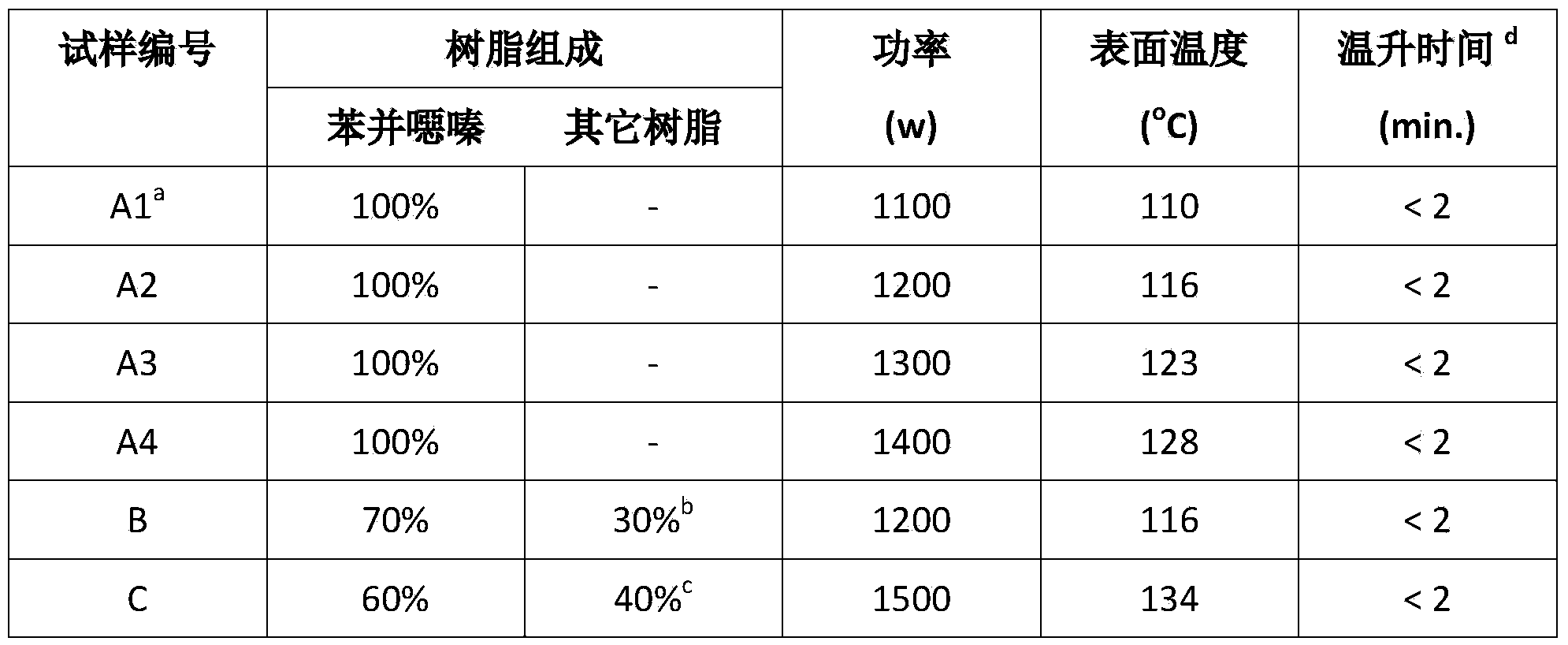

Embodiment 1

[0047]Soak the glass cloth in the benzoxazine resin solution, dry and remove the solvent to obtain the benzoxazine resin prepreg, and the glue content is 50%. Spread the benzoxazine resin prepreg, and then lay carbon paper and copper foil tape on it. After the laying is completed, cover the benzoxazine resin prepreg again. Finally, it is cured and molded at a temperature of 170°C, a pressure of 4-8 MPa, and a time of 180 minutes, and then heat-treated in an oven at 200°C for 120 minutes. The copper foil electrode and the wire are connected by welding to produce a carbon fiber electric heating plate A.

preparation Embodiment 2

[0049] The benzoxazine resin in the above preparation example 1 was blended at a ratio of 70% by weight and 30% by weight of epoxy resin. Then, carbon fiber electric heating plate B was prepared according to the steps in Example 1 for the preparation of high-power carbon fiber electric heating plate.

Embodiment 3

[0051] The benzoxazine resin in the above Preparation Example 1 was blended at a ratio of 60% by weight and 40% by weight of bismaleimide. Then, a carbon fiber electric heating plate C was prepared according to the steps in Example 1 for the preparation of a high-power carbon fiber electric heating plate.

[0052] Example 4 of the preparation of high-power carbon fiber electric heating plate

[0053] The benzoxazine resin in the above preparation example 1 is blended with epoxy resin and bismaleimide at a weight percentage of 60% by weight, wherein the epoxy resin accounts for 10%. The bismaleimide accounted for 30%; then the carbon fiber electric heating plate D was prepared according to the steps in Example 1 for the preparation of the high-power carbon fiber electric heating plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com