Patents

Literature

36results about How to "No waterproof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

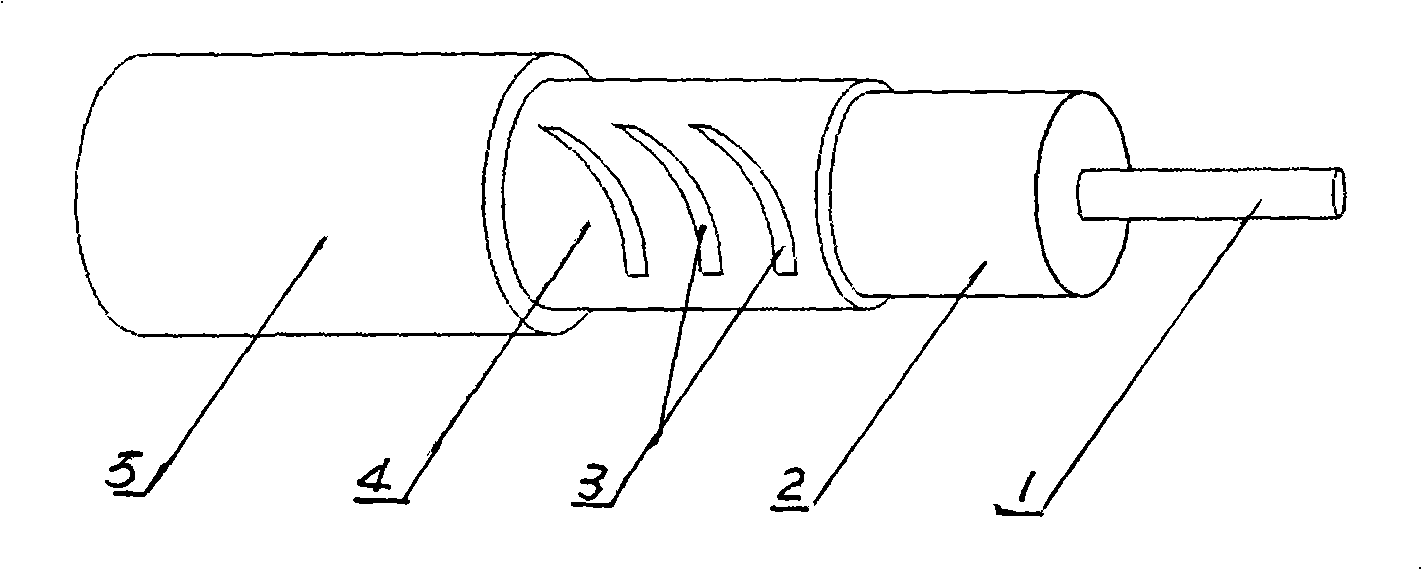

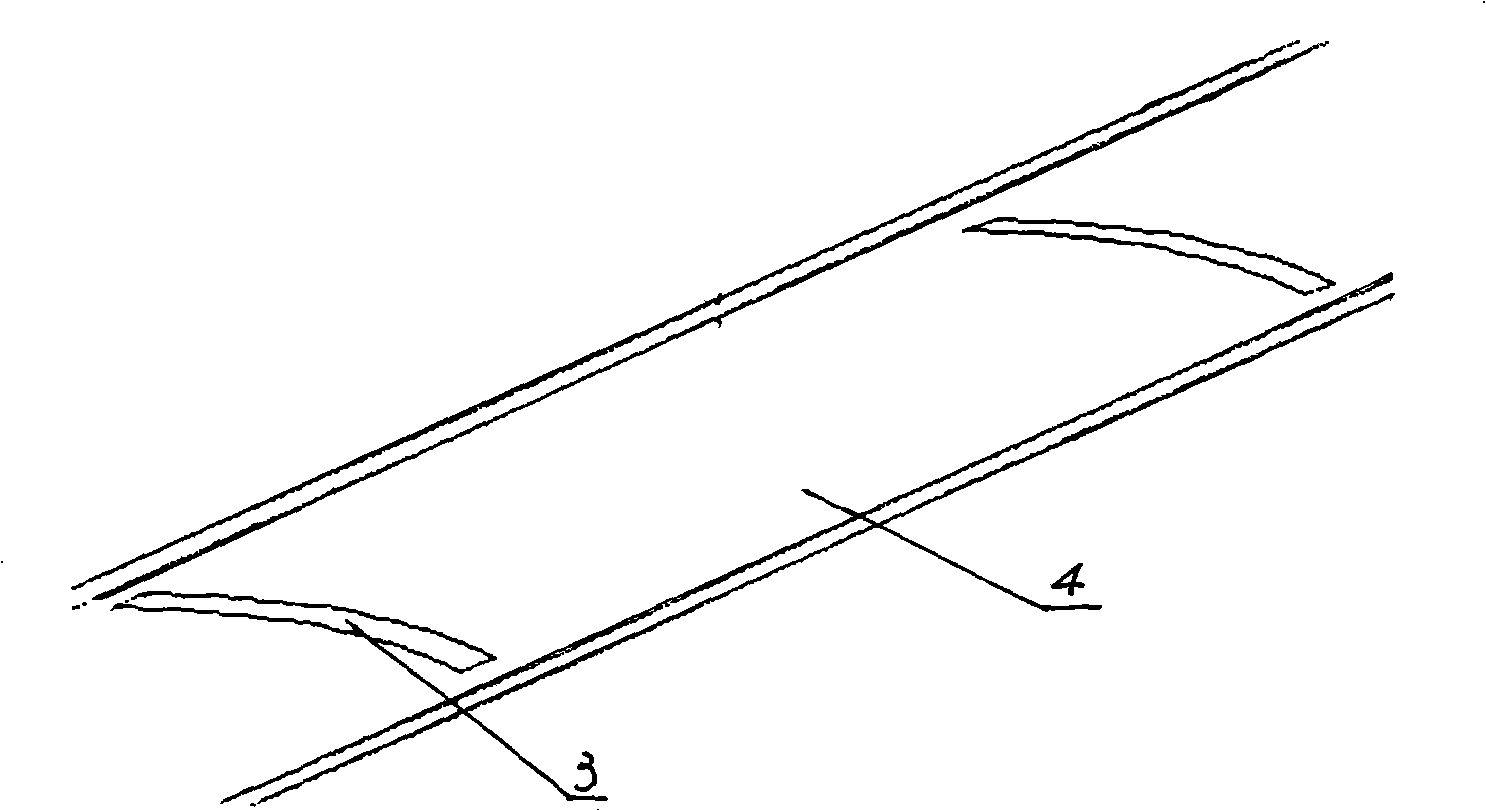

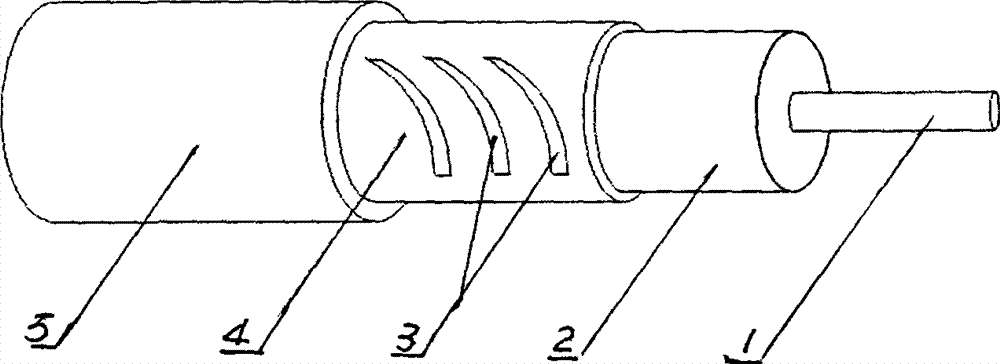

Broad band radiation type leak coaxial cable for subway and its production method

ActiveCN101404350AUniformly foamed poresUniform field strengthCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsInsulation layerElectrical conductor

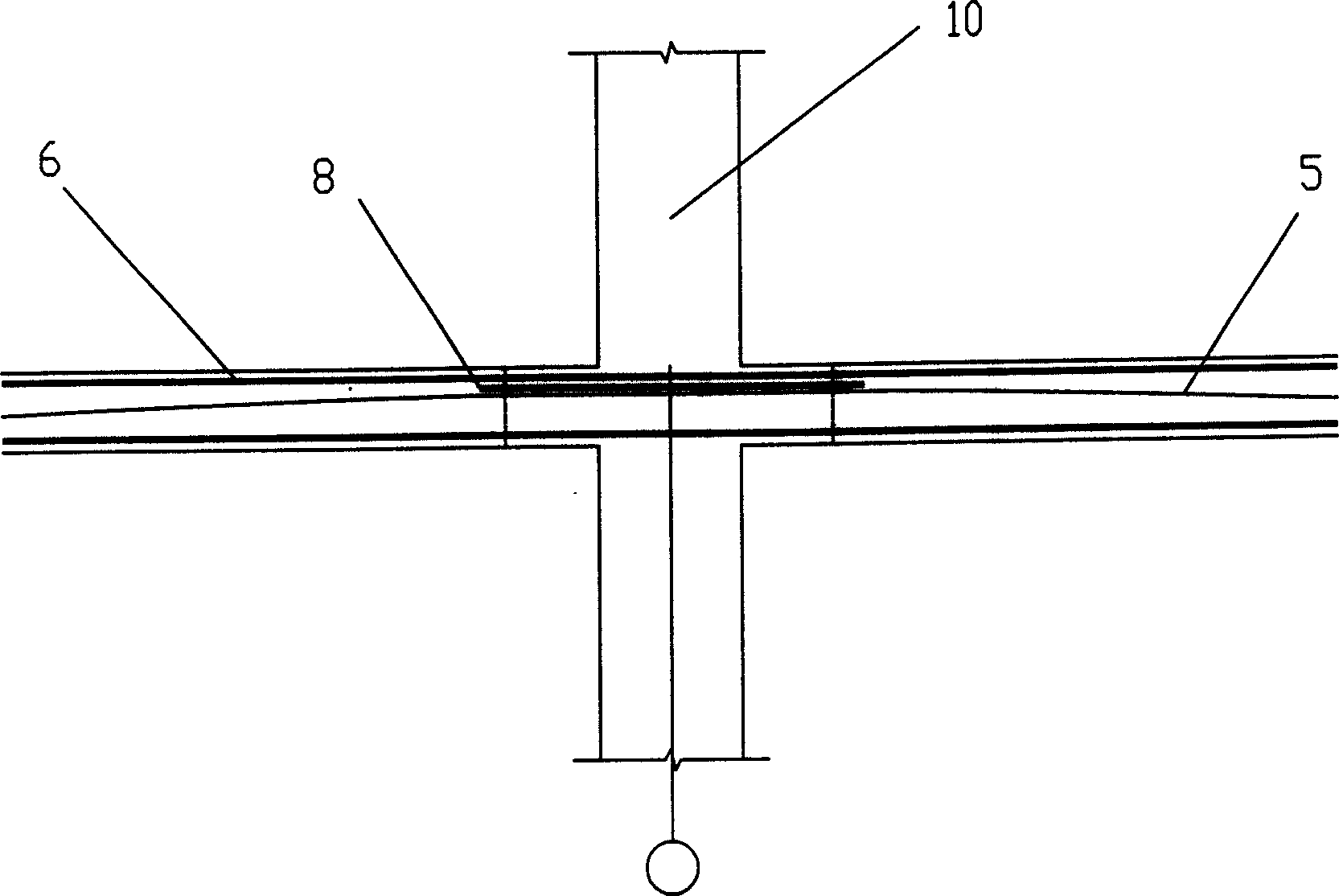

The invention relates to a broadband radial pattern leaky coaxial cable used for subway and a manufacturing method thereof, and the leaky coaxial cable has the double functions of transmission line of information and duplexer. The structure of the leaky coaxial cable consists of an inner conductor, an insulation layer, an outer conductor and a jacket, wherein, the inner conductor is externally covered with the insulation layer which is externally covered with the outer conductor that is externally sheathed with the jacket, and the insulation layer that covers on the surface of the inner conductor adopts nitrogen or carbon dioxide physical foam to form a foamed polyethylene insulation layer; cambered slotted holes are opened on a clutch gold belt of the outer conductor covered outside the insulation layer. The manufacturing method comprises the steps: (1) a spiral wrinkle inner conductor is manufactured by longitudinal covering welding and embossing by using a copper strip; (2) the nitrogen or the carbon dioxide are adopted to be injected into the smelted polyvinyl plastics, and then the physical foamed polyethylene insulation layer is formed on the surface of the inner conductor by extrusion and cladding; (3) the slotted holes broken out by the clutch gold belt of the outer conductor are the cambered slotted holes; (4) the clutch gold belt of the outer conductor is covered on the insulation layer longitudinally, and the surface of the clutch gold belt of the outer conductor is crowded and covered with the jacket.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

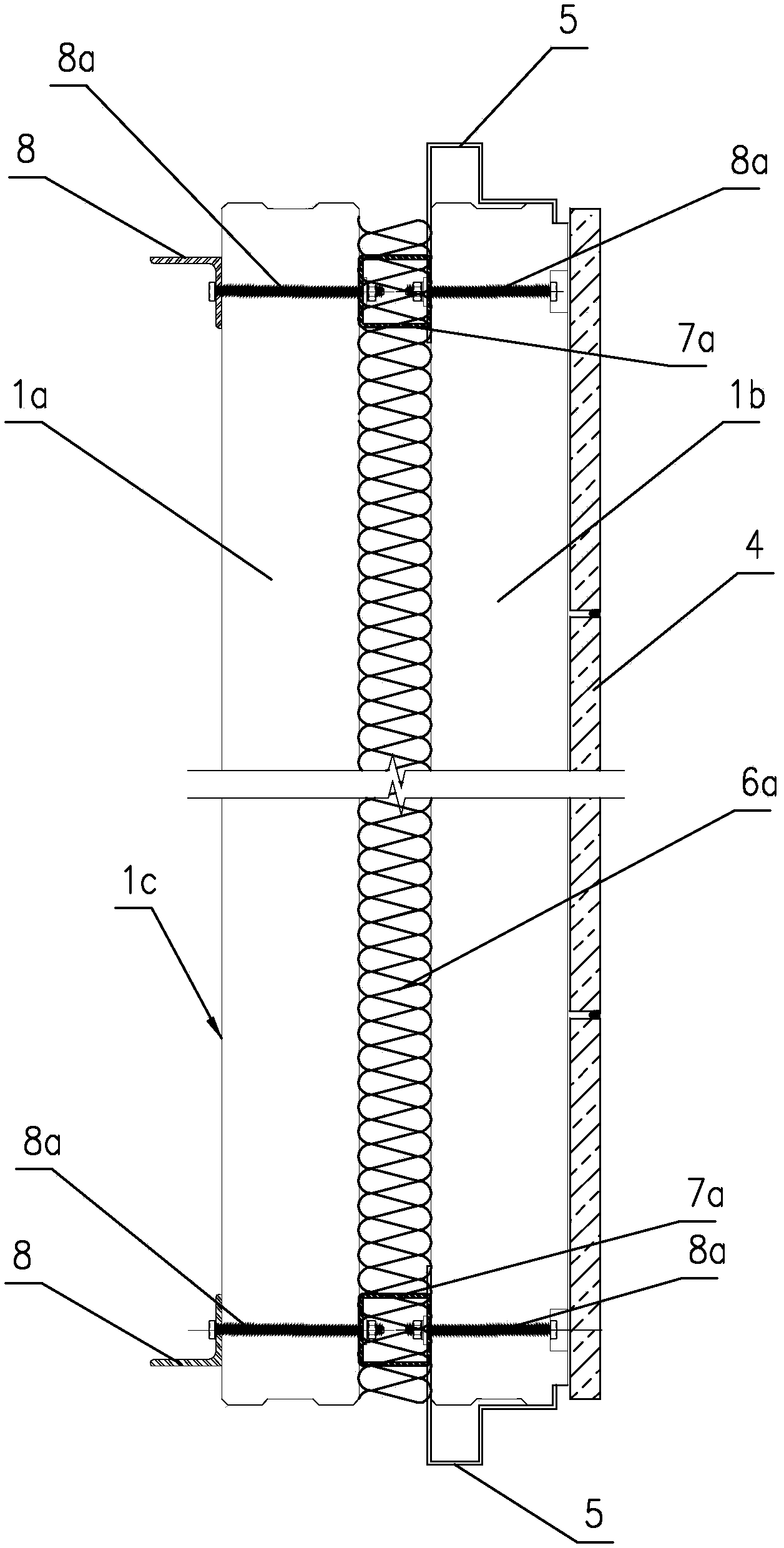

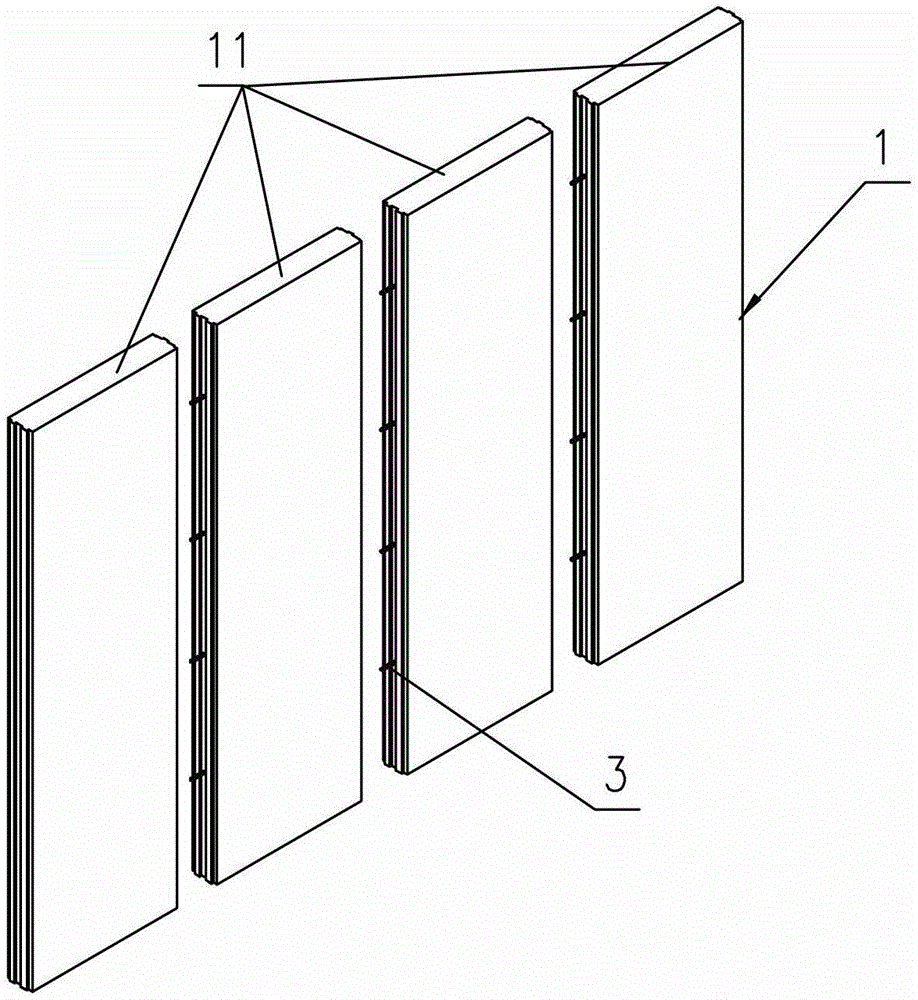

Self-heat-insulation decoration integral multifunctional light-weight concrete composite plate and curtain wall

The invention discloses a self-heat-insulation decoration integral multifunctional light-weight concrete composite plate, which mainly consists of an inner light-weight concrete plate, an outer light-weight concrete plate and heat insulation materials, wherein the outer surface of the outer light-weight concrete plate is used for installing a decoration surface; the inner light-weight concrete plate and the outer light-weight concrete plate are opposite, and in addition, a gap is formed between the inner light-weight concrete plate and the outer light-weight concrete plate; the heat insulation materials are filled in the gap; the inner light-weight concrete plate and the outer light-weight concrete plate are connected and fixed through a connecting structure; and pendants used for being connected with a building main body structure are arranged on the inner light-weight concrete plate. The self-heat-insulation decoration integral multifunctional light-weight concrete composite plate is based on the self structural strength of the light-weight concrete plate; in addition, the double-layer structure formed by the inner and outer light-weight concrete plates and the heat insulation materials arranged in the gap formed between the inner and outer light-weight concrete plates are suitable to be used for building exterior wall enclosure systems in northern area with cold weather; high strength, heat insulation performance, fireproof performance, waterproof performance, low dry shrinkage rate and good sound isolation performance are realized; the factory prefabrication and the in-site installation are realized; construction waste is little; and the installation is safe and fast.

Owner:GUANGDONG HEYUAN LIANTIAN BUILDING INDZATION MFG

Fire-extinguishing bomb thrown through unmanned aerial vehicle

The invention discloses a fire-extinguishing bomb thrown through an unmanned aerial vehicle. The fire-extinguishing bomb comprises a shell, a fire-extinguishing agent, a hanging mechanism and a starting system; the starting system comprises a self-inflammation unit, a throwing delayer, an infrared detector and a starter, the fire-extinguishing agent is placed in the shell, and the starting system is installed on the shell; and the throwing delayer penetrates through the shell, the upper end of the throwing delayer is connected with the hanging mechanism which is a lifting ring, and the lower end of the throwing delayer is connected with the starter. The fire-extinguishing bomb thrown through the unmanned aerial vehicle is reasonable in design, simple in structure, good in exploding orientation of the fire-extinguishing bomb, little in detonating energy and capable of achieving umbrella type covering; and throwing can be conducted towards a fire scene by diversified means, fire fighting is more convenient to be conducted for a site, where people cannot easily enter, with a high mountain and a thick wood, and meanwhile safety of a rescue person is protected.

Owner:BEIJING SHENGTAI FIRE FIGHTING EQUIP

Fructus forsythiae volatile oil medical hydrocolloid dressing and preparation method thereof

InactiveCN101670126AGood hygroscopicityNon-irritatingAbsorbent padsBandagesPolymer scienceFoaming agent

The invention discloses a fructus forsythiae volatile oil medical hydrocolloid dressing that is formed by sticking two layers of materials, one layer of which is base mounting material, and the other layer is composed of the following components in terms of percentage by mass: 0.1%-10% of fructus forsythiae volatile oil, 1%-20% of water-soluble high polymer material, 10%-60% of rubber substrate, 0.01%-0.2% of antioxidant, 1%-9.7% of foaming agent and 0.1%-87.89% of water, wherein the total content of the above components is 100%. The method for preparing the dressing comprises the following steps of: first, adding a proper amount of water in water-soluble high polymer material so as to over-swelling the water-soluble high polymer material, then adding fructus forsythiae volatile oil to form I-phase solution, then adding antioxidant in the rubber substrate and evenly stirring to form II-phase solution, hybrid mixing I-phase solution and II-phase solution, adding foaming agent and rest water, fully stirring, transitively coating on the base mounting material, refrigerating and then unfreezing. The fructus forsythiae volatile oil medical hydrocolloid dressing has exact treatment effect, is safe and reliable, and has obviously economic benefits.

Owner:姚辉

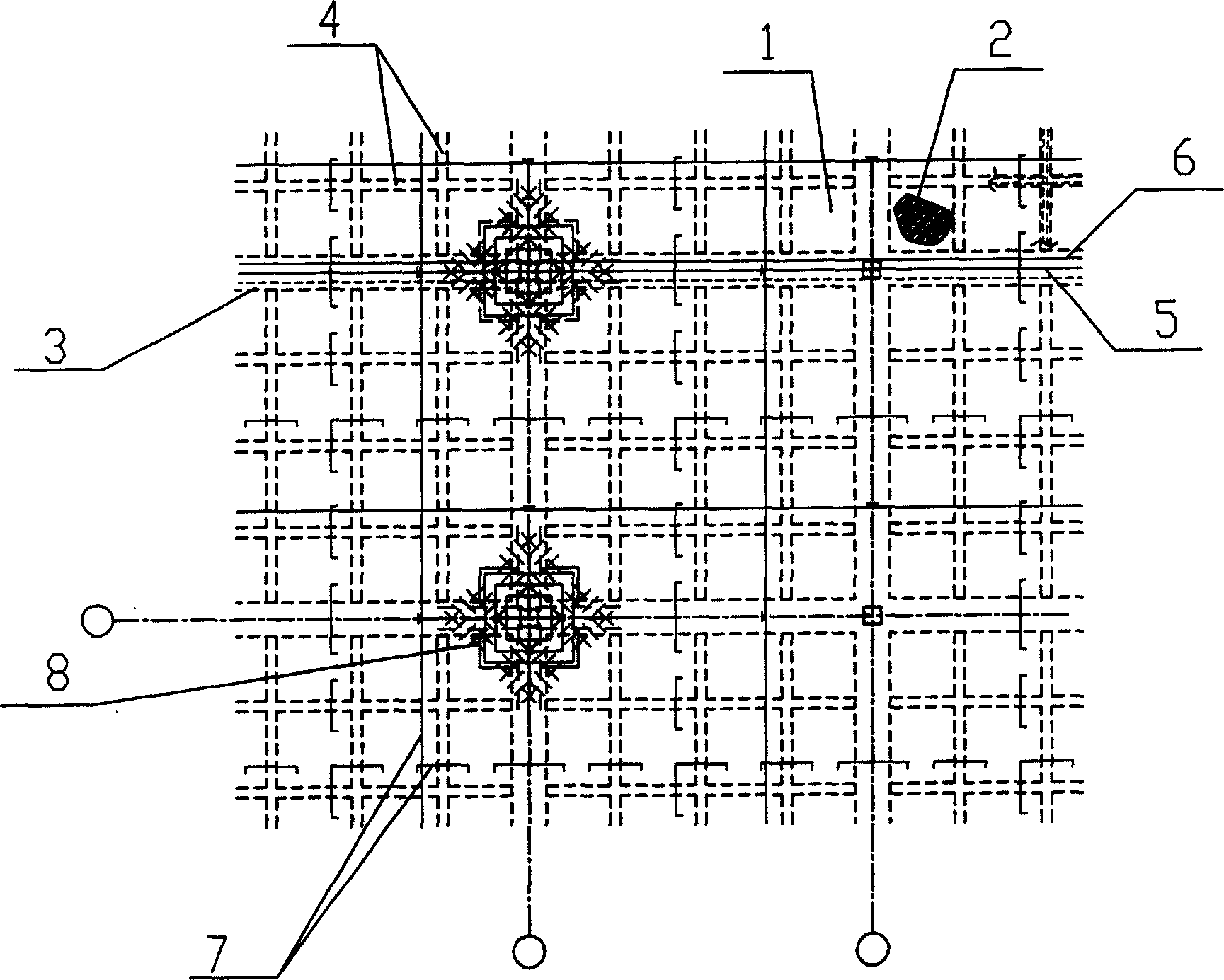

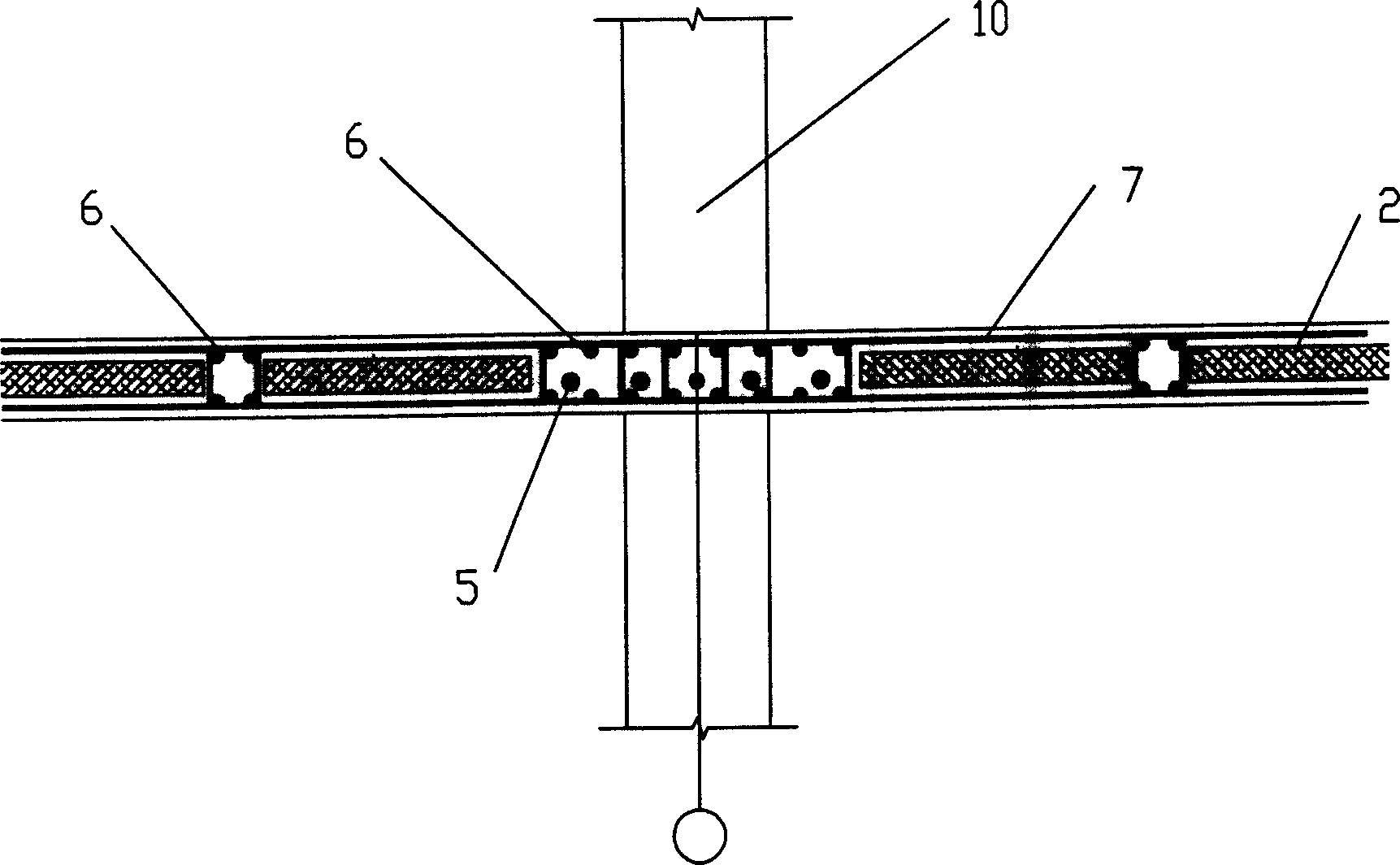

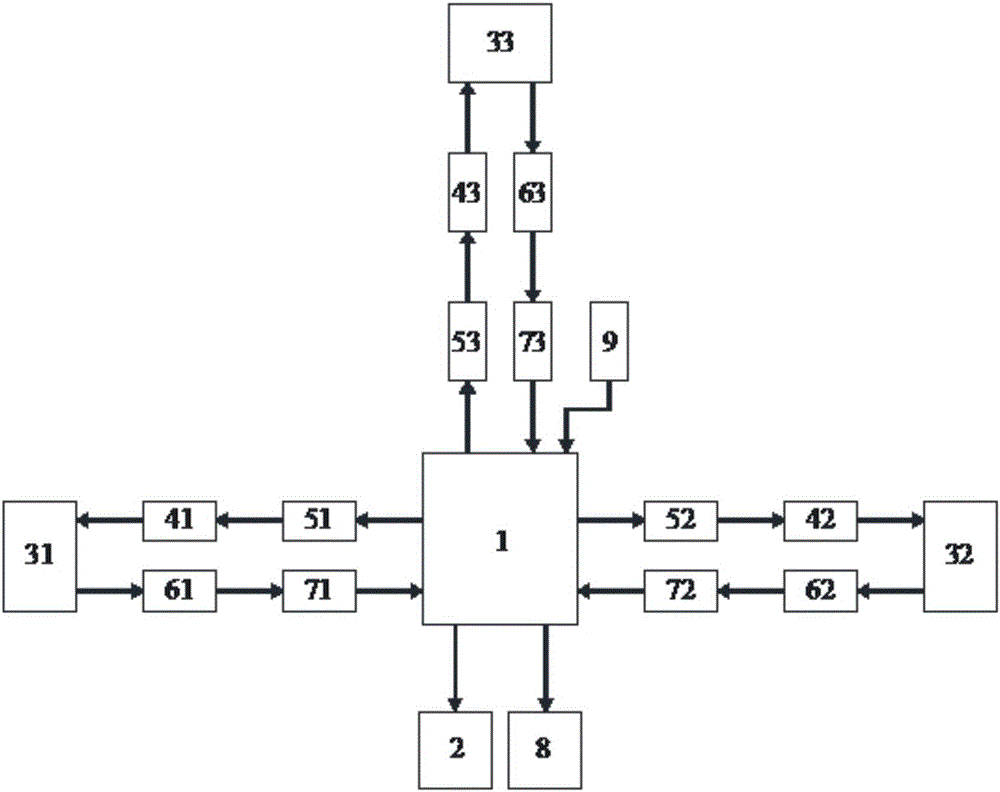

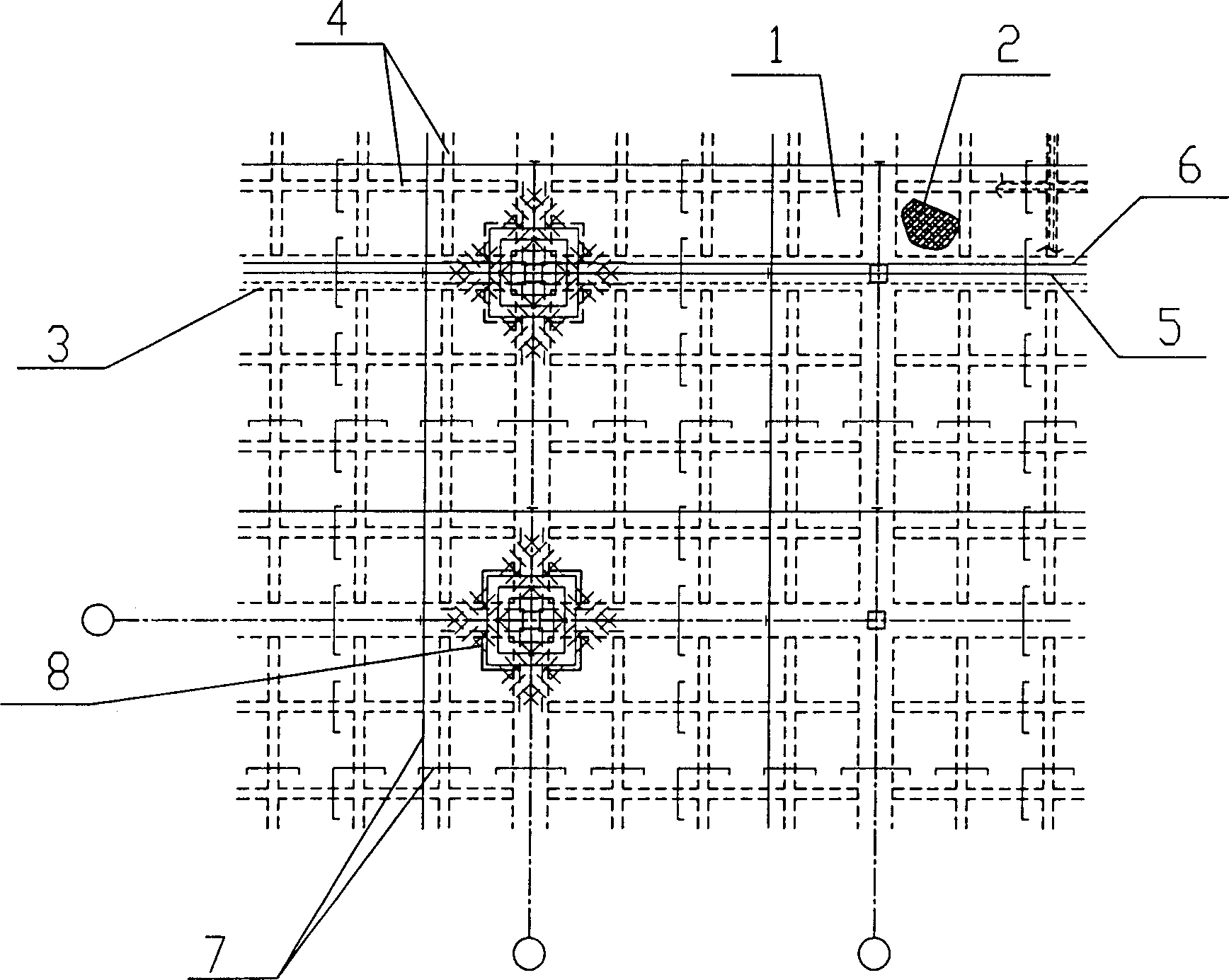

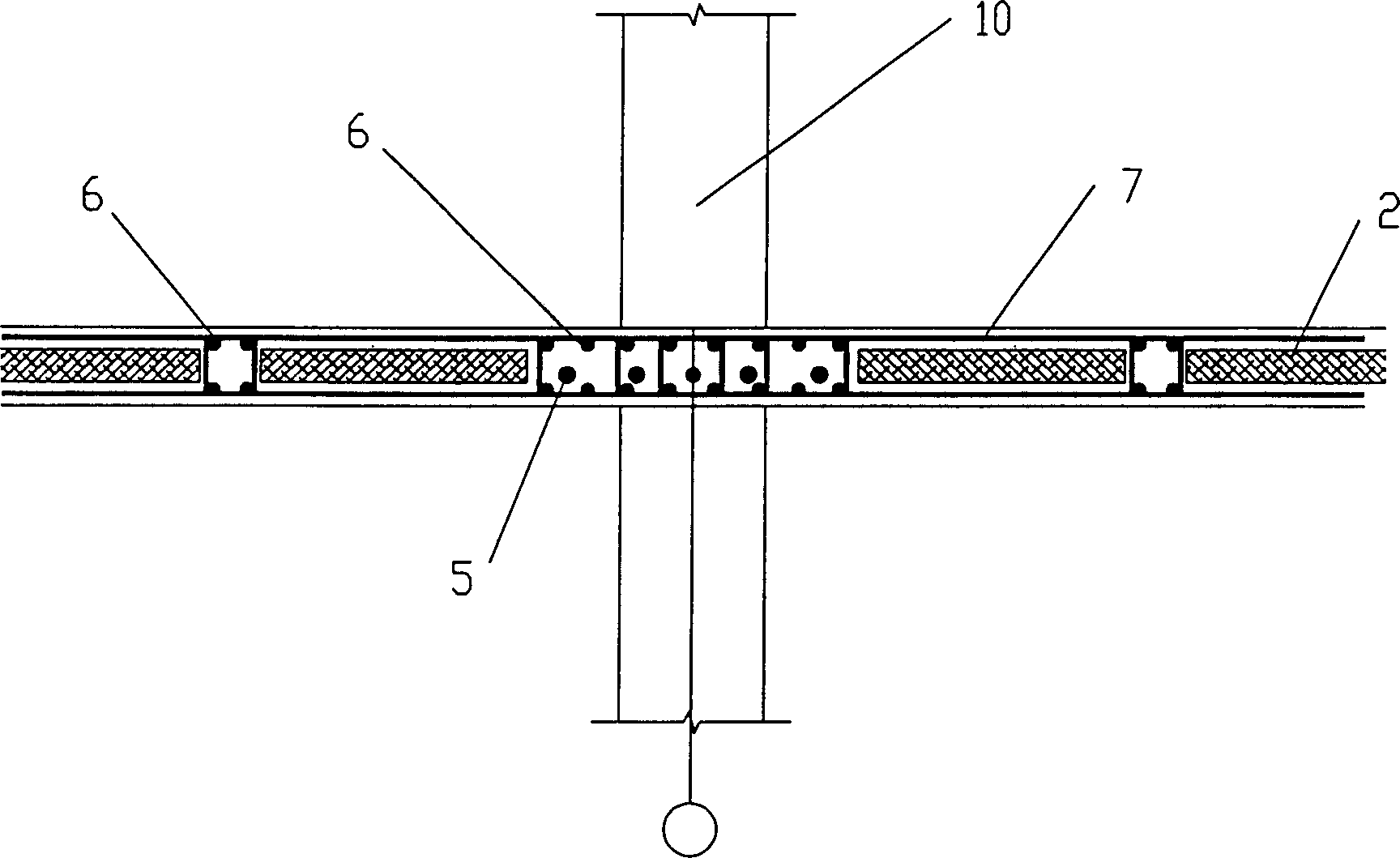

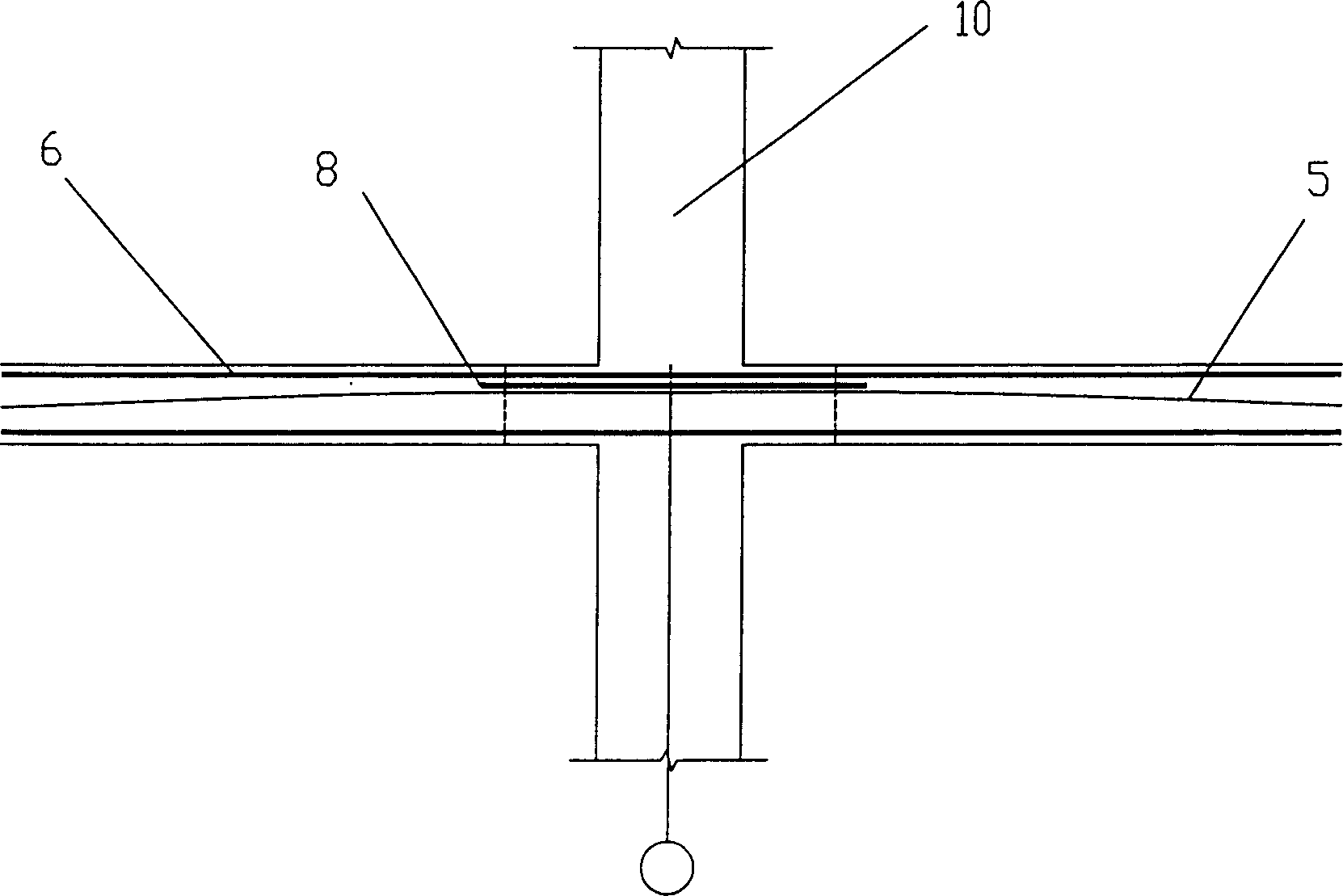

In-site prestressed concrete sandwiched composite beamless floor structure system and construction method

This invention discloses a kind of sandwich and compound beamless slab construction of watering prestress concrete and its constructing method. This construction includes beamless slab body, ribs of inner main and dark slabs and ribs of inner secondary dark slabs with cross arranged. The prestess and stress concrete reinforced bars are arranged in the ribs of main and dark slabs, and the stress concrete reinforced bars are laid out in the upper and lower crust of beamless slab body and in the inner secondary dark slabs with cross arranged. The inner space of the body is stuffed with polystyrene foam sandwich boards. In the job site, first, the form board is propped up and the prestress bars are arranged and stretched and drawn; second, the polystyrene foam sandwich boards should be laid out and fastened and the stress bars are arranged; then the concrete is poured and shaped into the construction, which can satisfy the constructing load-bearing requirements like fireproofing, sound insulation, heat insulation, high-intensity and light quality. Such beamless slab can be used in civilian and various industries construction.

Owner:胡战波

Medical dressing of Shuanghuanglian form-stable hydrogel and preparation method thereof

InactiveCN101664564ANo peeling reactionGood economic benefitsAbsorbent padsBandagesIrritationToxicity

The invention discloses a medical dressing of a Shuanghuanglian form-stable hydrogel and a preparation method thereof. The medical dressing of the Shuanghuanglian form-stable hydrogel is formed by laminating of two layers of materials, one layer is formed by subbottom mounting material, and the other layer comprises: Shuanghuanglian extract, polyoxygen enol, polyoxyethylene, glycerol and water. The preparation method of the medical dressing comprises the following steps: weighing the Shuanghuanglian extract, and dissolving the Shuanghuanglian extract in water, adding the polyoxygen enol, stirring to lead the mixture to swell, then adding the glycerol, stirring to lead the polyoxygen enol to be dissolved, adding the polyoxyethylene after cooling, stirring and dissolving, degassing in vacuum, and coating the mixture on the subbottom mounting material by transitivity, thus obtaining the medical dressing of the Shuanghuanglian form-stable hydrogel. The medical dressing is stuck on the diseased parts of patients, has no toxicity, nonirritant, no irritability and no stripping response, as well as functions of high hygroscopicity, deodorization, water resistance and the like simultaneously.

Owner:姚辉

Combined obstacle meeting alarm phone

InactiveCN105847475ANo pollution in the processSimple modulationMeasurement devicesAlarmsMicrocontrollerAudio power amplifier

The invention discloses a combined obstacle meeting alarm phone. The mobile phone is provided with an integrated microcontroller, an infrared transmission drive circuit, a mobile phone left infrared diode, a mobile phone right infrared diode, an infrared receiving drive circuit, a mobile phone left photosensitive diode, a mobile phone right photosensitive diode, a frequency signal drive amplifying circuit, an ultrasonic transmitter, an ultrasonic receiver, an ultrasonic received signal amplifier and a temperature sensor. Through the mobile phone screen, an alarm mode can be selected, and the default alarm distance is adjusted in a user-defined manner. When an obstacle is within an alarm range, an image appears in the mobile phone screen and / or a mobile phone loudspeaker sounds to give out alarm information. Accidents are prevented when a user watches the mobile phone.

Owner:QINGDAO UNIV

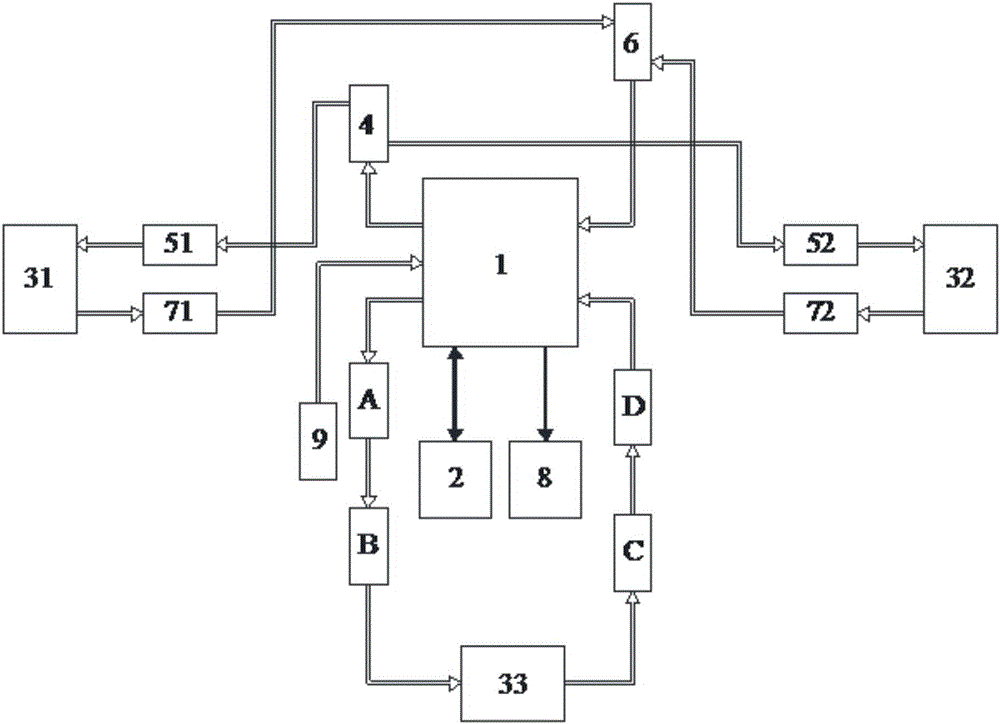

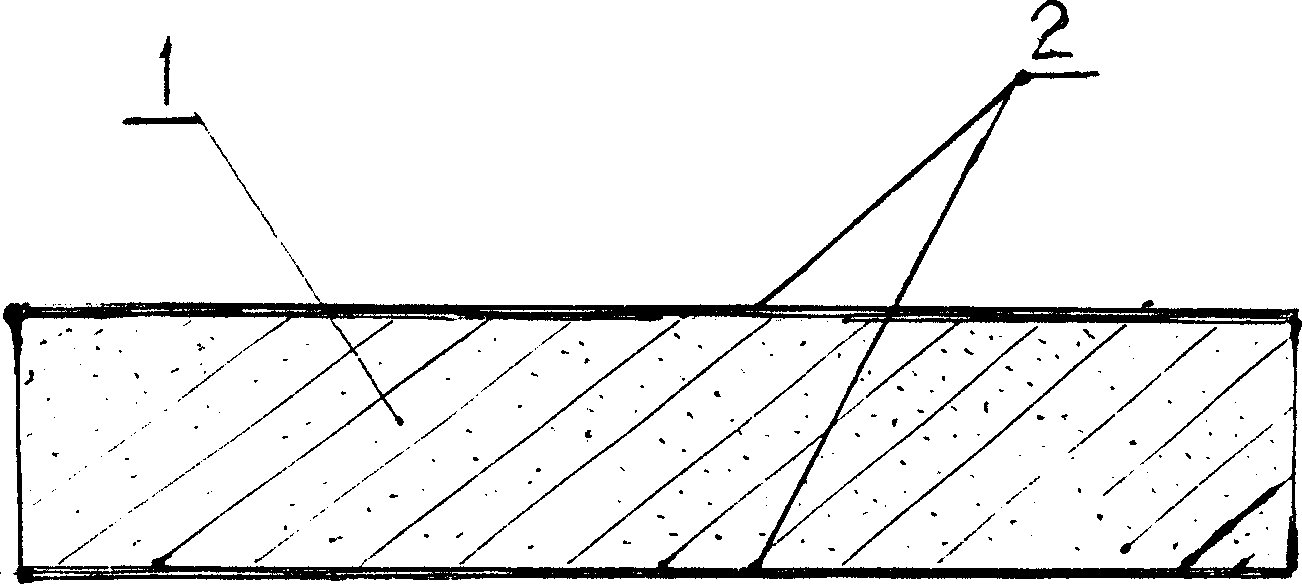

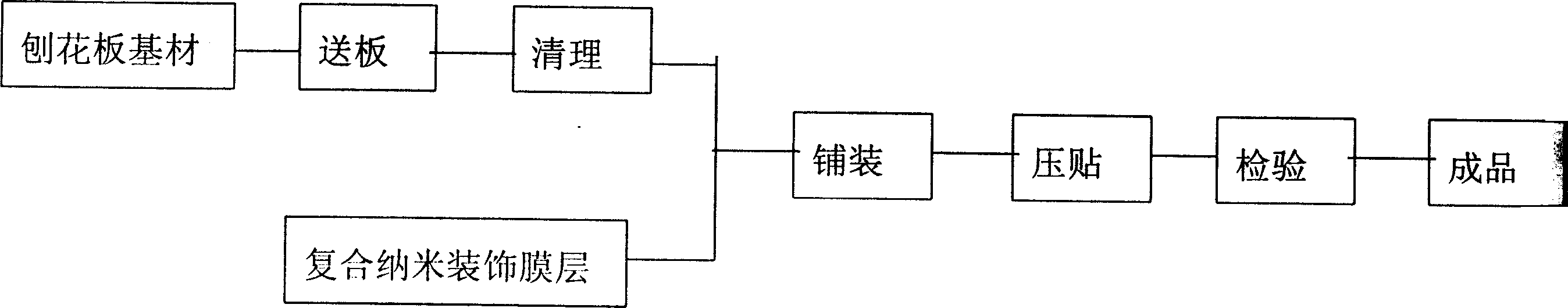

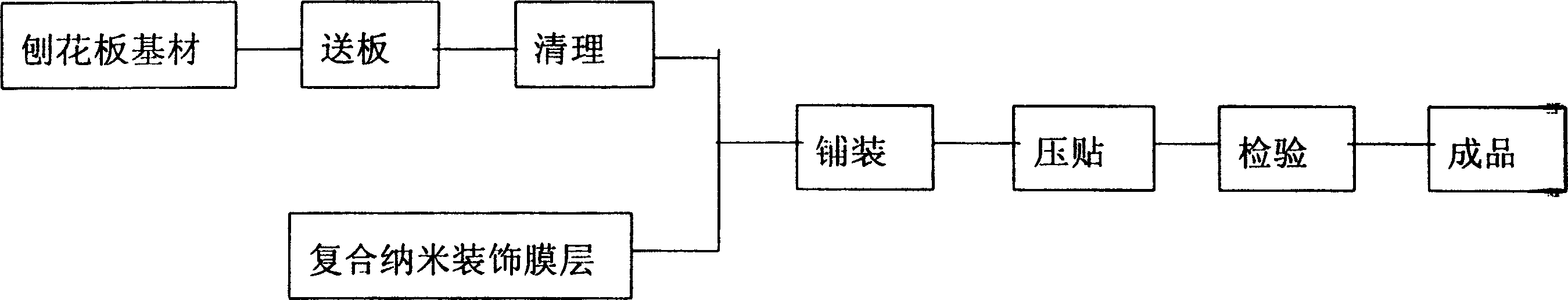

Nano sterilized health care board and producing method

InactiveCN1562630AExcellent materialThe production method is simple and scientificSynthetic resin layered productsWood layered productsIonNanometre

Owner:上海美连商务信息咨询服务有限公司

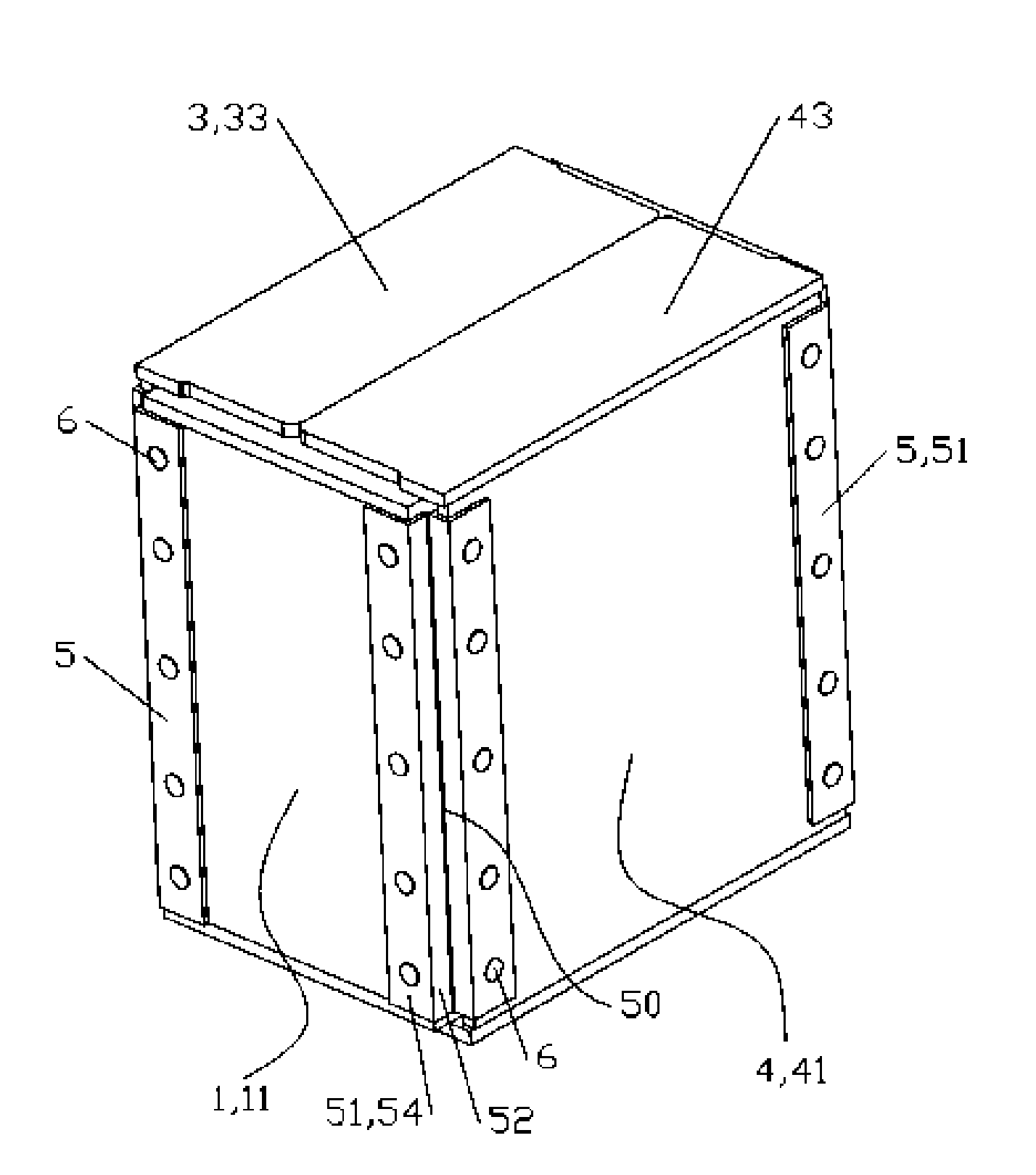

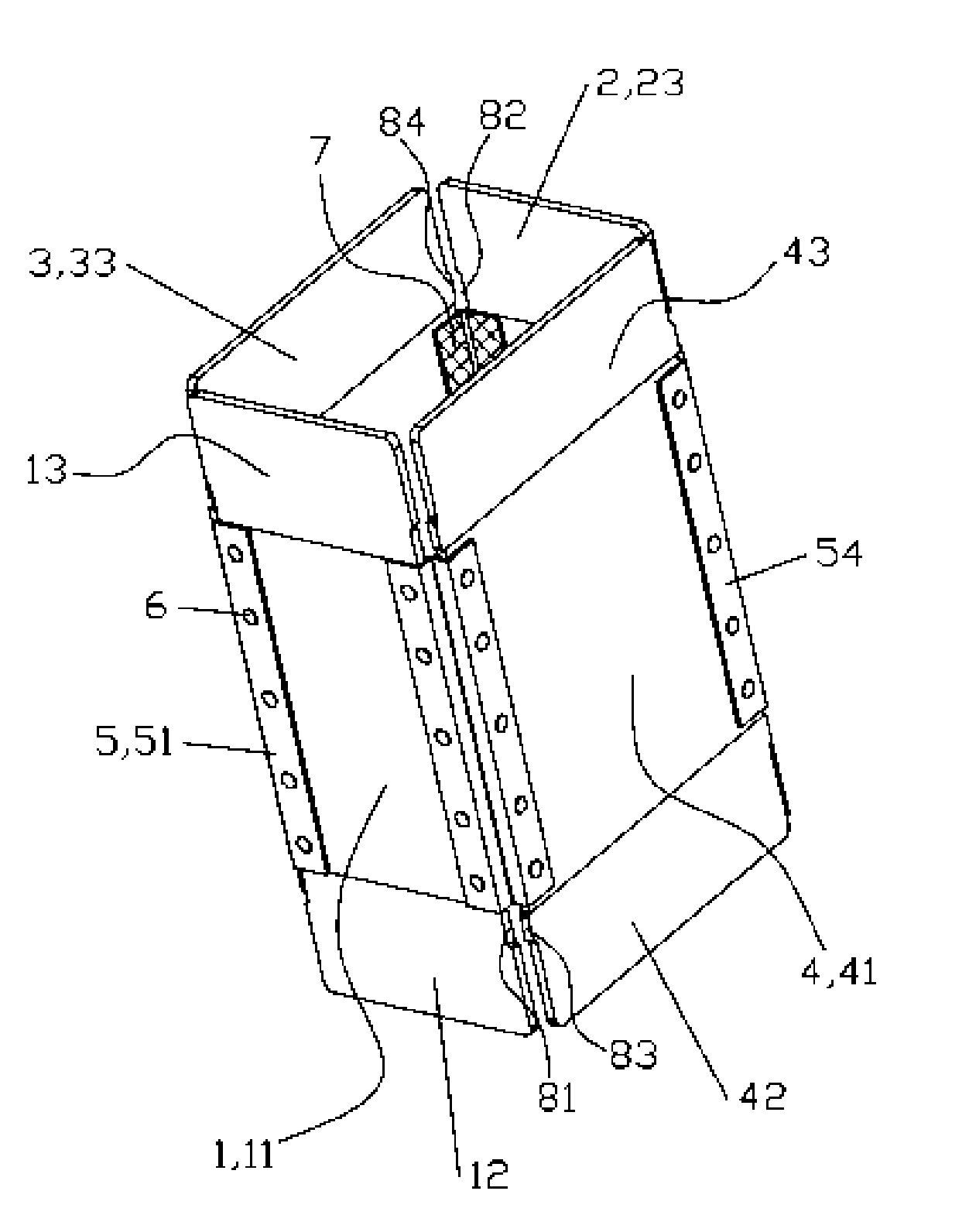

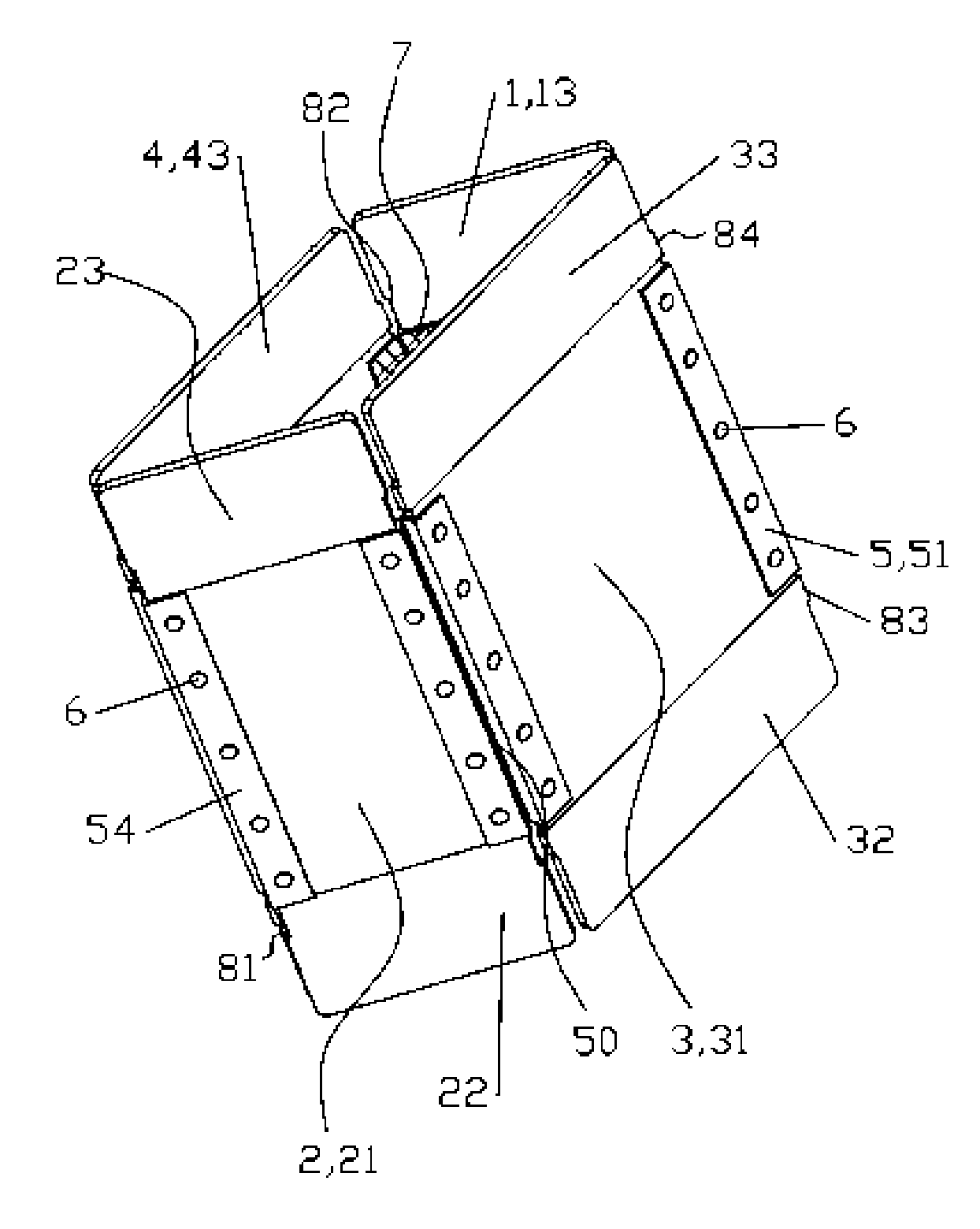

Folding type hollow plate reusable container

ActiveCN101665167ASimple structureEasy to foldPackage recyclingNon-removalbe lids/coversHinge angleEngineering

The invention discloses a folding type hollow plate reusable container, comprising a first plate, a second plate, a third plate, a fourth plate and four hinges, wherein the first plate, the second plate, the third plate and the fourth plate are all plastic hollow plates; the first plate and the second plate have same structure and are arranged in parallel from front to rear; the third plate and the fourth plate have same structure and are arranged in parallel from left to right; the four plates are stamped and bent so as to form a front plate, a rear plate, a left plate, a right plate, four top covers and four bottom covers; two sides of the front plate, the rear plate, the left plate and the right plate are respectively provided with three to eight rivet mounting holes, and the four hinges are also provided with corresponding rivet mounting holes; the first plate, the second plate, the third plate and the fourth plate are riveted and fixed by the four hinges and rivets, thus connecting together and forming a rectangular box body; and protecting strips made of PE cotton are attached on the parts of the four hinges in the box body and protect stored articles in the box from being collided and scratched. The folding type hollow plate container has simple structure, convenient folding and less occupied space.

Owner:JIANGSU HUASHENG PLASTIC

Heat-insulating TPU protective film

InactiveCN109554132ALong-term elasticityImprove physical propertiesFireproof paintsAntifouling/underwater paintsCross-linkMicrosphere

The invention discloses a heat-insulating TPU (thermoplastic polyurethane) protective film which comprises a base material layer and a rubber layer arranged at the lower part of the base material layer, wherein the base material layer is a TPU film, the upper surface of the TPU film is provided with a heat insulation coating, the heat insulation coating comprises the following components in partsby weight: 20-50 parts of a heat-insulating filler, 50-80 parts of polyurethane acrylic resin, 0.01 to 6 parts of a cross-linking agent and 0.01 to 10 parts of a metal oxide; wherein the heat-insulating filler is hollow glass beads or / and high-molecular microspheres. The TPU film provided by the invention has good mechanical property, heat resistance, heat insulation property and oil contaminationresistance, and is especially suitable for kitchen utensils and building outer windows.

Owner:SHANGHAI NAR INDAL +1

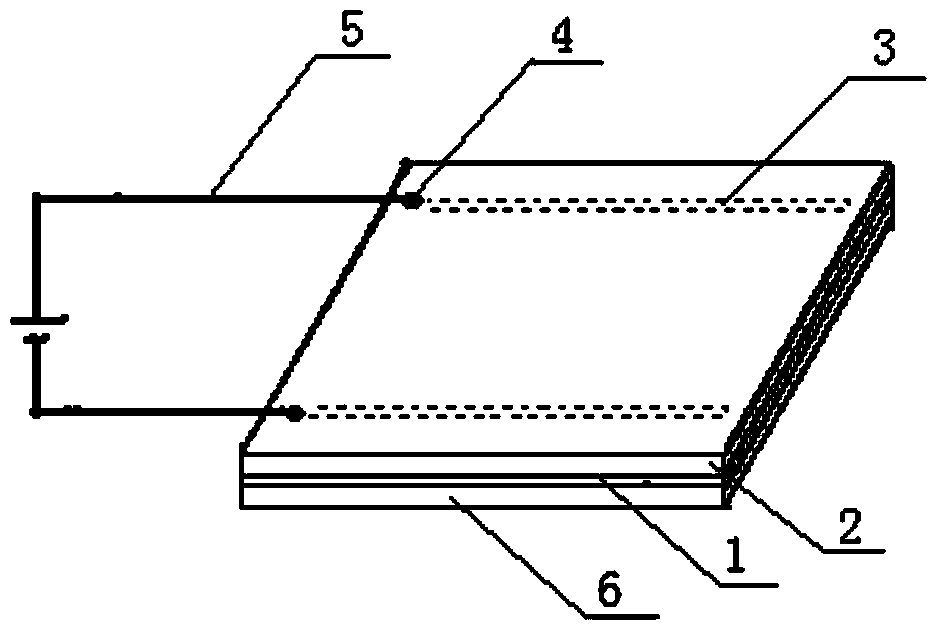

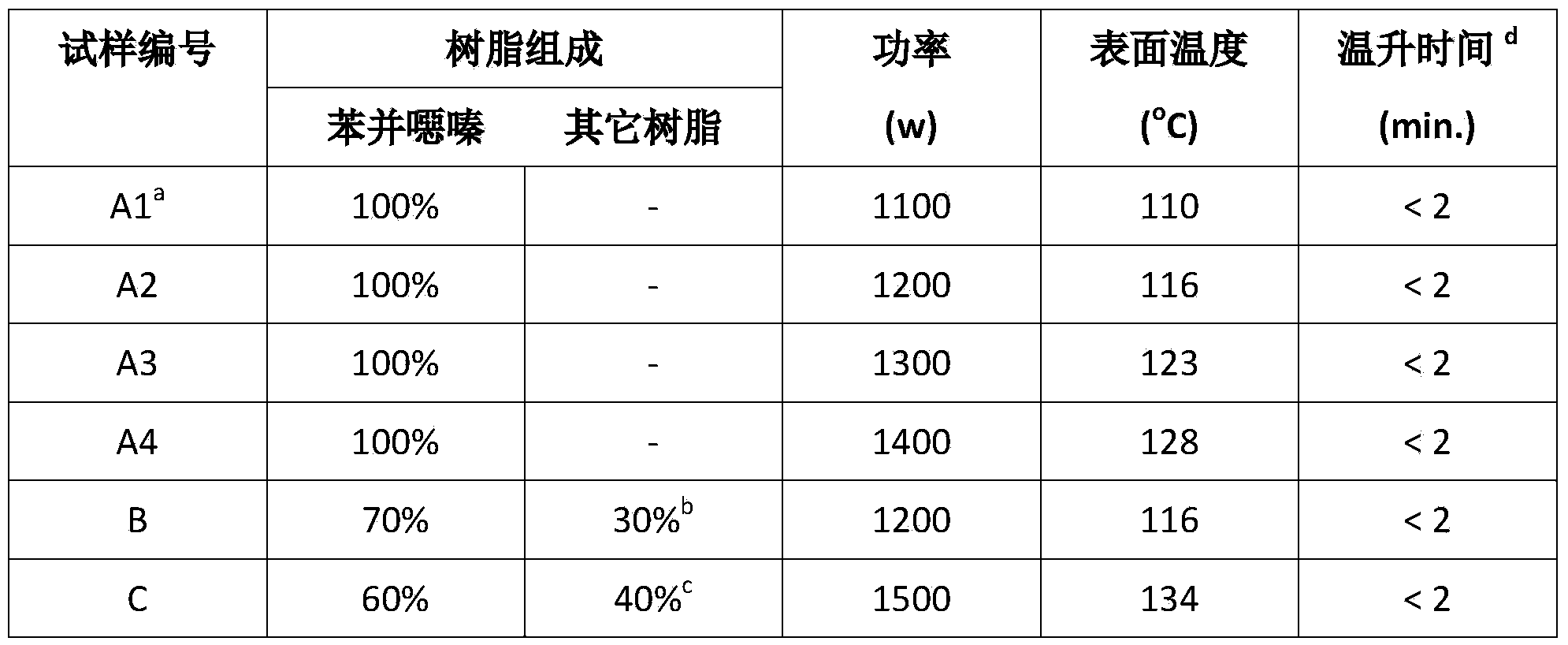

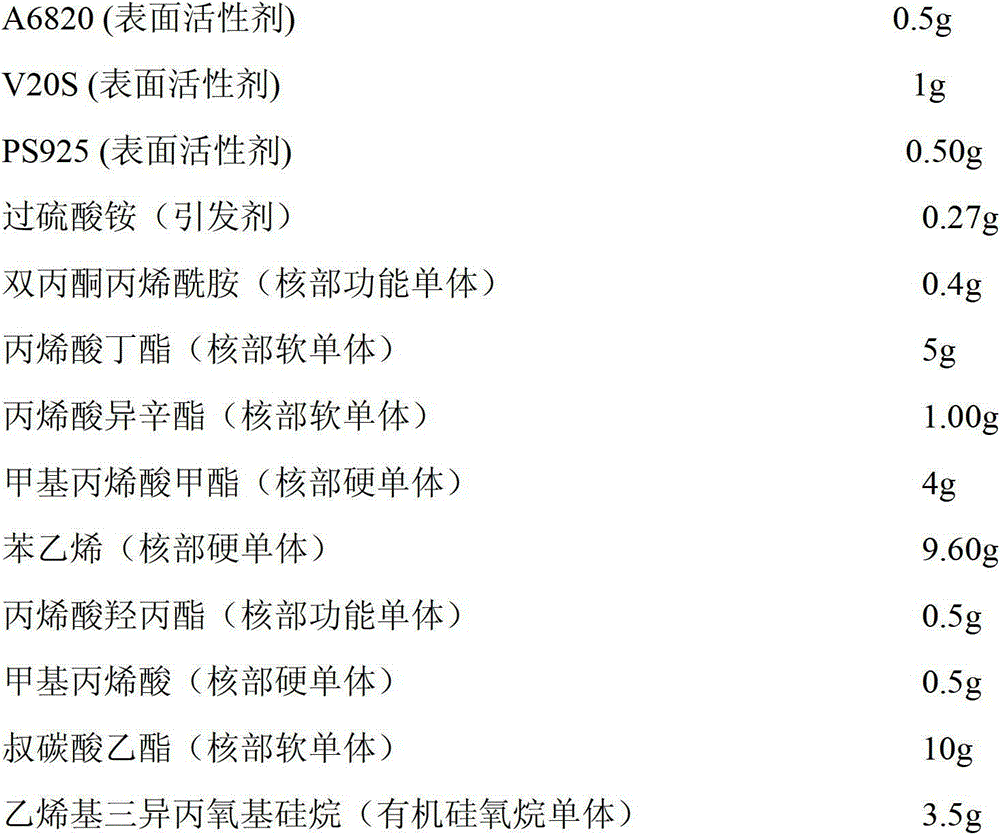

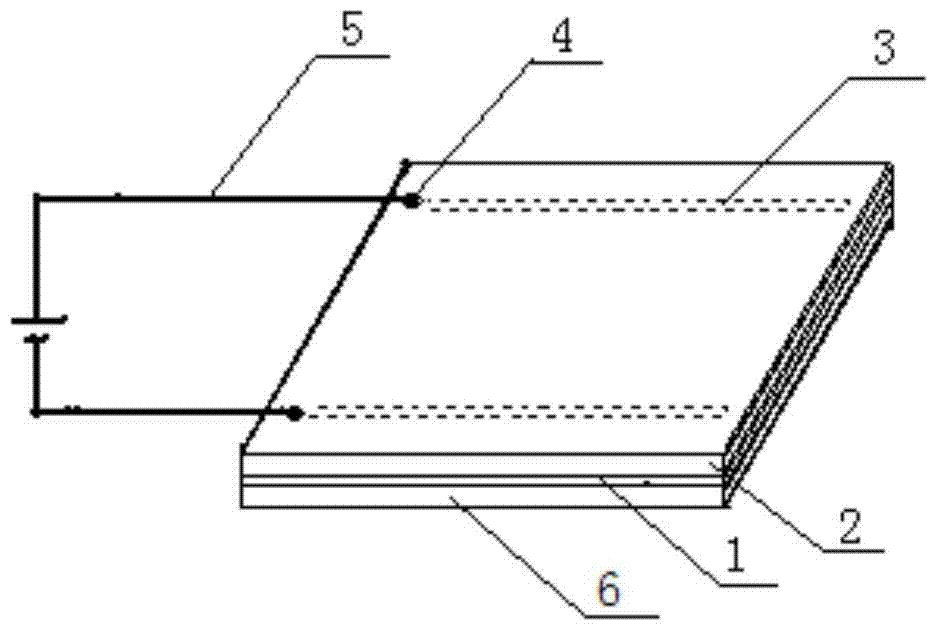

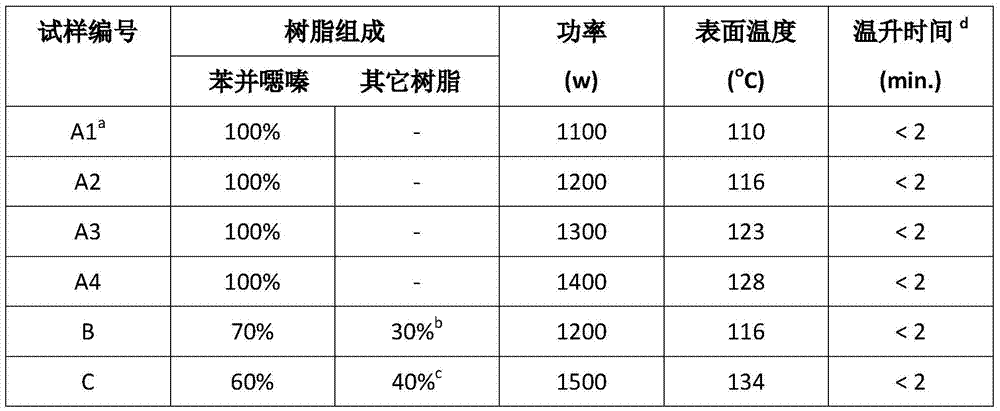

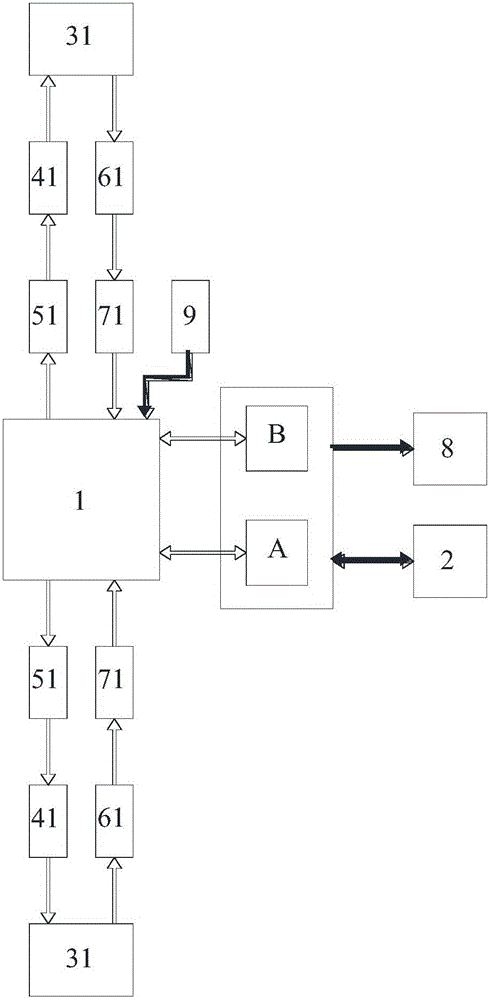

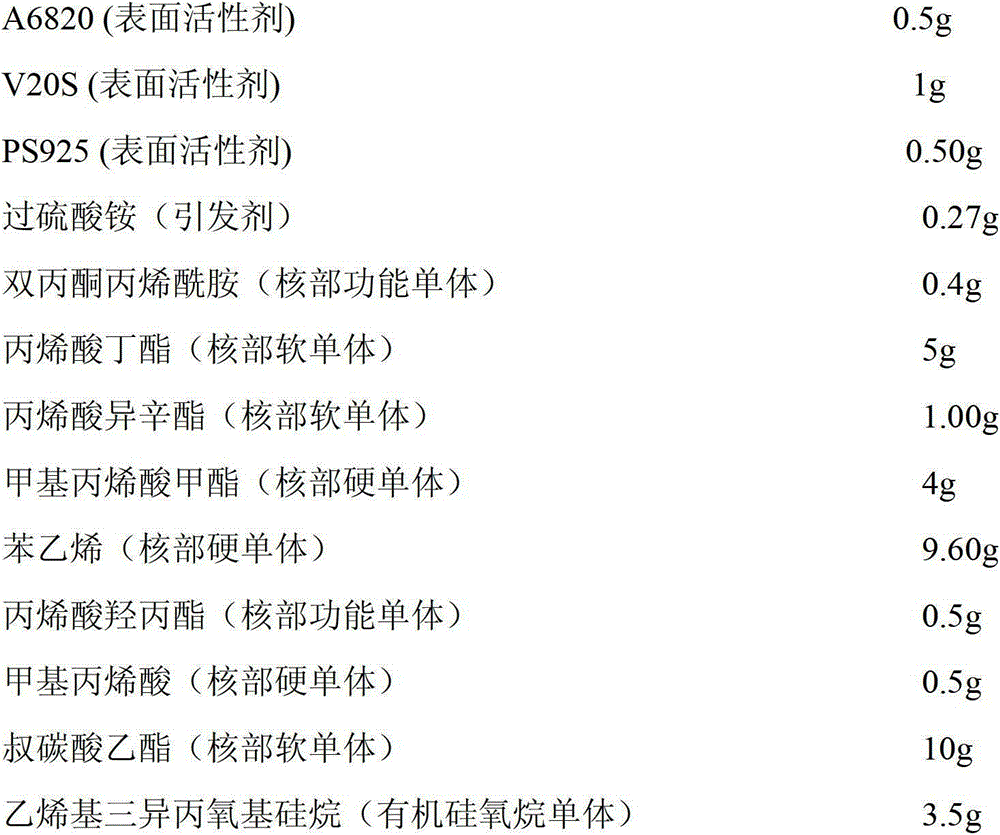

High-power carbon fiber electric heating plate, production process and application device

ActiveCN104290414ALow costTo promote metabolismLamination ancillary operationsSynthetic resin layered productsEpoxyFiber

The invention discloses a high-power carbon fiber electric heating plate, a production process and an application device. The high-power carbon fiber electric heating plate comprises a plurality of layers, namely a benzoxazine resin insulation layer I, carbon paper and a benzoxazine resin insulation layer II which are sequentially arranged from top to bottom, wherein the middle layer of carbon paper is encapsulated up and down by the benzoxazine resin insulation layer I and the benzoxazine resin insulation layer II; a conductive material in contact with the carbon paper is also encapsulated between the carbon paper and the benzoxazine resin insulation layer I and / or between the carbon paper and the benzoxazine resin insulation layer II; the conductive material is used as an electrode and is connected with a power supply by virtue of a lead; the benzoxazine resin insulation layer I and the benzoxazine resin insulation layer II respectively comprise cured benzoxazine resin or cured and modified benzoxazine resin; glass cloth is used as a resin reinforcing material. According to the high-power carbon fiber electric heating plate, epoxy resin is replaced by the benzoxazine resin and the modified resin of the benzoxazine resin, so that the carbon fiber electric heating plate with high-heat-resistance upper and lower insulation layers and development power reaching 1100-1500w is obtained.

Owner:SHANDONG UNIV

Electronic textile

The invention discloses an electronic textile. The electronic textile is formed by carrying out one-wrap and three-weft blending on 30-40% by volume of electroluminescent wire and 60-70% by volume of fiber, wherein the electroluminescent wire is electrically contacted with a 6-12V direct current power supply by virtue of a lead. The electroluminescent wire (EL wire) produces no heat, is nonradiative and waterproof, can bend at will, is bright in colour and rich in lighting colours and has power consumption of being only 50-70% of that of a light-emitting diode, and the EL wire is fibrous and can be blended with other fibers, so that the EL wire can be fused with the textile into a whole, the EL wires in different colours can be adopted as required, and the textile can obtain particoloured visual effect.

Owner:WUXI YUTONG FABRIC IND

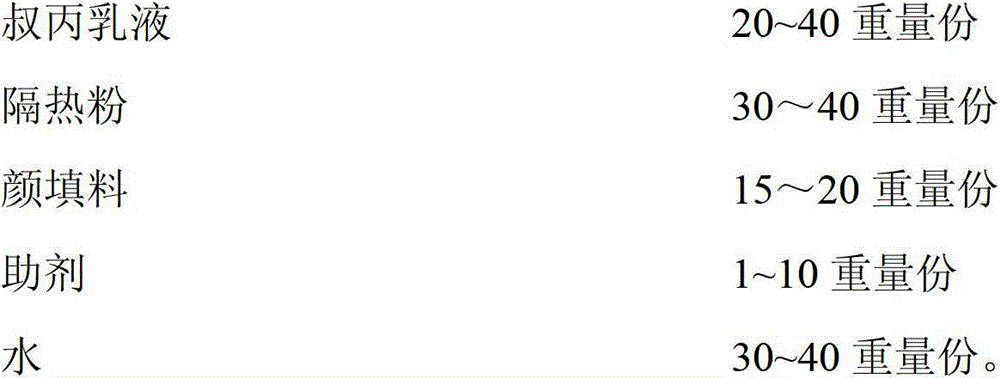

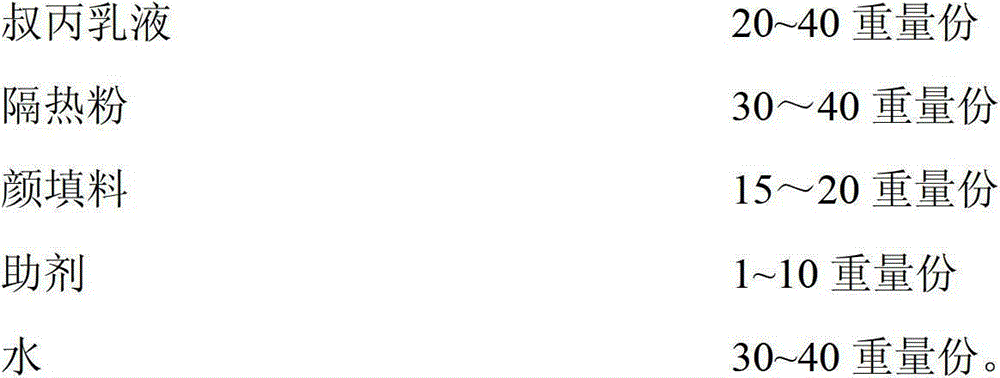

Reflective thermal insulation paint, preparation and applications thereof

ActiveCN103937363AGood air permeabilityReduce the temperatureAntifouling/underwater paintsPaints with biocidesThermal insulationEmulsion

The invention relates to the field of thermal insulation construction material, and specifically relates to a reflective thermal insulation paint, preparation and applications thereof. The reflective thermal insulation paint is composed of the following components in parts by weight: 20 to 40 parts of tert-acetic styrene acrylic emulsion, 30 to 40 parts of thermal insulation powder, 15 to 20 parts of pigments and fillers, 1 to 10 parts of auxiliary agent, and 30 to 40 parts of water. The reflective paint is composed of tert-acetic styrene acrylic emulsion and thermal insulation powder with a high reflectivity, has the advantages of no toxicity, no odor, waterproofness, and good gas permeability, and can effectively reflect the infrared rays in sunshine lights so as to reduce the temperature.

Owner:上海绿色建材研究中心有限公司

Preparation method for macromolecular plastic hollow plate

The invention discloses a macromolecular plastic hollow plate which comprises the following raw materials in parts by weight: mixed resin, polyethylene, flatting agent, polyethylene low-molecular waxdispersing agent, powdered colorant, ethyl alcohol solvent, organic pigment, color control agent, modified nanometer activated carbon, diisooctyl, reactive diluent, polyether amine, flexibilizer and curing agent. A preparation method for the macromolecular plastic hollow plate comprises the following steps: S1) smashing and mixing the raw materials; S2) adding additives; S3) pre-plasticizing; S4)setting under the conditions of pressurizing and cooling; S5) molding the product. The produced macromolecular plastic hollow plate is a green environment-friendly product, is non-toxic, non-pollution, waterproof, shake-proof, anti-aging, anti-corrosion and rich in color, is pollution-free to environment, is simple in use, is recyclable, and is reasonably utilized so as to realize renewable resources.

Owner:佛山市仁享精密五金塑料制品有限公司

Decorative fragrant mud and preparation process thereof

PendingCN114085613AAchieve zero additionPlay a decorative roleStarch coatingsLignin material coatingsBiologyOrganic chemistry

The invention discloses decorative fragrant mud and a preparation process thereof, the raw materials are natural plant aromatic substances, resin, wood and the like, the processed fragrant mud coating can emit the natural aromatic odor of plants, can be used as a decorative material, can play roles in refreshing air and improving the environment, and is non-toxic, free of peculiar smell, waterproof, and good in air permeability, the product has the decorative effect, people can enjoy the incense culture at any time without going out while playing a role in decoration, and the incense can be widely applied to residential houses, office buildings, hospitals, schools, hotels, shopping malls, underground garages, pharmaceutical factories, food factories, ships and the like to improve the indoor environment air quality, decoration and protection.

Owner:郭建美

Cement-based quick repair mortar for internal wall and preparation method of mortar

The invention discloses cement-based quick repair mortar for an internal wall and a preparation method of the mortar, wherein the cement-based quick repair mortar for the internal wall is prepared from the following ingredients in parts by weight: 200-300 parts of ordinary Portland cement, 100-200 parts of sulphoaluminate cement, 600-650 parts of sand, 150-200 parts of water, 100 parts of a filler, 1-5 parts of lithium sulfate, 2 parts of a water reducing agent, 1.5-3 parts of cellulose ether, 10-30 parts of rubber powder, 0.5-2 parts of a wetting tackifier and 2-6 parts of a retarder. The cement-based quick repair mortar for the internal wall prepared by the invention has few components, low raw material cost and good shrinkage and expansibility, can be dried quickly, does not shrink or crack, is waterproof, and does not require maintenance.

Owner:湖南大迈新材科技有限公司

Rock paint

The invention relates to the field of building paint, in particular to rock paint. The invention is characterized in that the rock paint comprises natural marble powder, paint, water, cellulose, thickening agents, defoaming agents, lubricating agents and corrosion agents. The invention has the advantages of good safety performance, water prevention, heat insulation, safe and simple operation and low cost.

Owner:郎叶龙

A high-power carbon fiber electric heating plate, processing technology and application equipment

ActiveCN104290414BLow costTo promote metabolismLamination ancillary operationsSynthetic resin layered productsEpoxyFiber

The invention discloses a high-power carbon fiber electric heating plate, a production process and an application device. The high-power carbon fiber electric heating plate comprises a plurality of layers, namely a benzoxazine resin insulation layer I, carbon paper and a benzoxazine resin insulation layer II which are sequentially arranged from top to bottom, wherein the middle layer of carbon paper is encapsulated up and down by the benzoxazine resin insulation layer I and the benzoxazine resin insulation layer II; a conductive material in contact with the carbon paper is also encapsulated between the carbon paper and the benzoxazine resin insulation layer I and / or between the carbon paper and the benzoxazine resin insulation layer II; the conductive material is used as an electrode and is connected with a power supply by virtue of a lead; the benzoxazine resin insulation layer I and the benzoxazine resin insulation layer II respectively comprise cured benzoxazine resin or cured and modified benzoxazine resin; glass cloth is used as a resin reinforcing material. According to the high-power carbon fiber electric heating plate, epoxy resin is replaced by the benzoxazine resin and the modified resin of the benzoxazine resin, so that the carbon fiber electric heating plate with high-heat-resistance upper and lower insulation layers and development power reaching 1100-1500w is obtained.

Owner:SHANDONG UNIV

Intelligent shoes with function of giving alarm via ultrasonic waves when meeting obstacle

InactiveCN105768326AWith obstacle alarm functionImprove securityFootwearAcoustic wave reradiationMicrocontrollerAudio power amplifier

The invention belongs to the technical field of intelligent wearing and relates to a pair of intelligent shoes with a function of giving an alarm via ultrasonic waves when meeting an obstacle. Each of the intelligent shoes is provided with a single chip microprocessor, a first frequency signal driving and amplifying circuit, a second frequency signal driving and amplifying circuit, a first ultrasonic receiving signal amplifier, a second ultrasonic receiving signal amplifier, a WIFI connection module, a Bluetooth connection module, a temperature sensor, a first ultrasonic transmitter, a second ultrasonic transmitter, a first ultrasonic receiver and a second ultrasonic receiver. When the distance between the intelligent shoes and an obstacle is within an alarm range, alarm information is sent by a mobile phone and the ultrasonic ranging accuracy is high, so that the safety of a walker is good. Since a small-angle and small-blind-area ultrasonic sensor, the intelligent shoes have the advantages of accurate measurement, no contact, waterproof and anti-corrosion effects and low cost.

Owner:QINGDAO UNIV

A kind of reflective heat insulation coating and its preparation and application

ActiveCN103937363BEffective reflectionNo smellAntifouling/underwater paintsPaints with biocidesEmulsionThermal insulation

The invention relates to the field of thermal insulation construction material, and specifically relates to a reflective thermal insulation paint, preparation and applications thereof. The reflective thermal insulation paint is composed of the following components in parts by weight: 20 to 40 parts of tert-acetic styrene acrylic emulsion, 30 to 40 parts of thermal insulation powder, 15 to 20 parts of pigments and fillers, 1 to 10 parts of auxiliary agent, and 30 to 40 parts of water. The reflective paint is composed of tert-acetic styrene acrylic emulsion and thermal insulation powder with a high reflectivity, has the advantages of no toxicity, no odor, waterproofness, and good gas permeability, and can effectively reflect the infrared rays in sunshine lights so as to reduce the temperature.

Owner:上海绿色建材研究中心有限公司

Obstacle meeting ultrasonic alarm mobile phone

InactiveCN105847477AImprove ranging accuracyAnti-corrosionAlarmsTelephone set constructionsSignal amplifierLoudspeaker

The invention discloses an obstacle meeting ultrasonic alarm mobile phone. The mobile phone is provided with an integrated single-chip, a mobile phone left ultrasonic transmitter, a mobile phone right ultrasonic transmitter, a mobile phone head ultrasonic transmitter, a mobile phone left frequency signal drive amplifying circuit, a mobile phone right frequency signal drive amplifying circuit, a mobile phone head frequency signal drive amplifying circuit, a mobile phone left ultrasonic receiver, a mobile phone right ultrasonic receiver, a mobile phone head ultrasonic receiver, a mobile phone left ultrasonic received signal amplifier, a mobile phone right ultrasonic received signal amplifier, a mobile phone head ultrasonic received signal amplifier and a temperature sensor. An ultrasonic sensor is provided with near, middle and far alarm modes. The default alarm distances are 0.5m, 1m and 3m. When an obstacle is within an alarm range, an image appears in a mobile phone screen and / or a mobile phone loudspeaker sounds to give out alarm information. Various accidents are effectively prevented when a user watches the mobile phone.

Owner:QINGDAO UNIV

In-site prestressed concrete sandwiched composite beamless floor structure system and construction method

This invention discloses a kind of sandwich and compound beamless slab construction of watering prestress concrete and its constructing method. This construction includes beamless slab body, ribs of inner main and dark slabs and ribs of inner secondary dark slabs with cross arranged. The prestess and stress concrete reinforced bars are arranged in the ribs of main and dark slabs, and the stress concrete reinforced bars are laid out in the upper and lower crust of beamless slab body and in the inner secondary dark slabs with cross arranged. The inner space of the body is stuffed with polystyrene foam sandwich boards. In the job site, first, the form board is propped up and the prestress bars are arranged and stretched and drawn; second, the polystyrene foam sandwich boards should be laid out and fastened and the stress bars are arranged; then the concrete is poured and shaped into the construction, which can satisfy the constructing load-bearing requirements like fireproofing, sound insulation, heat insulation, high-intensity and light quality. Such beamless slab can be used in civilian and various industries construction.

Owner:胡战波

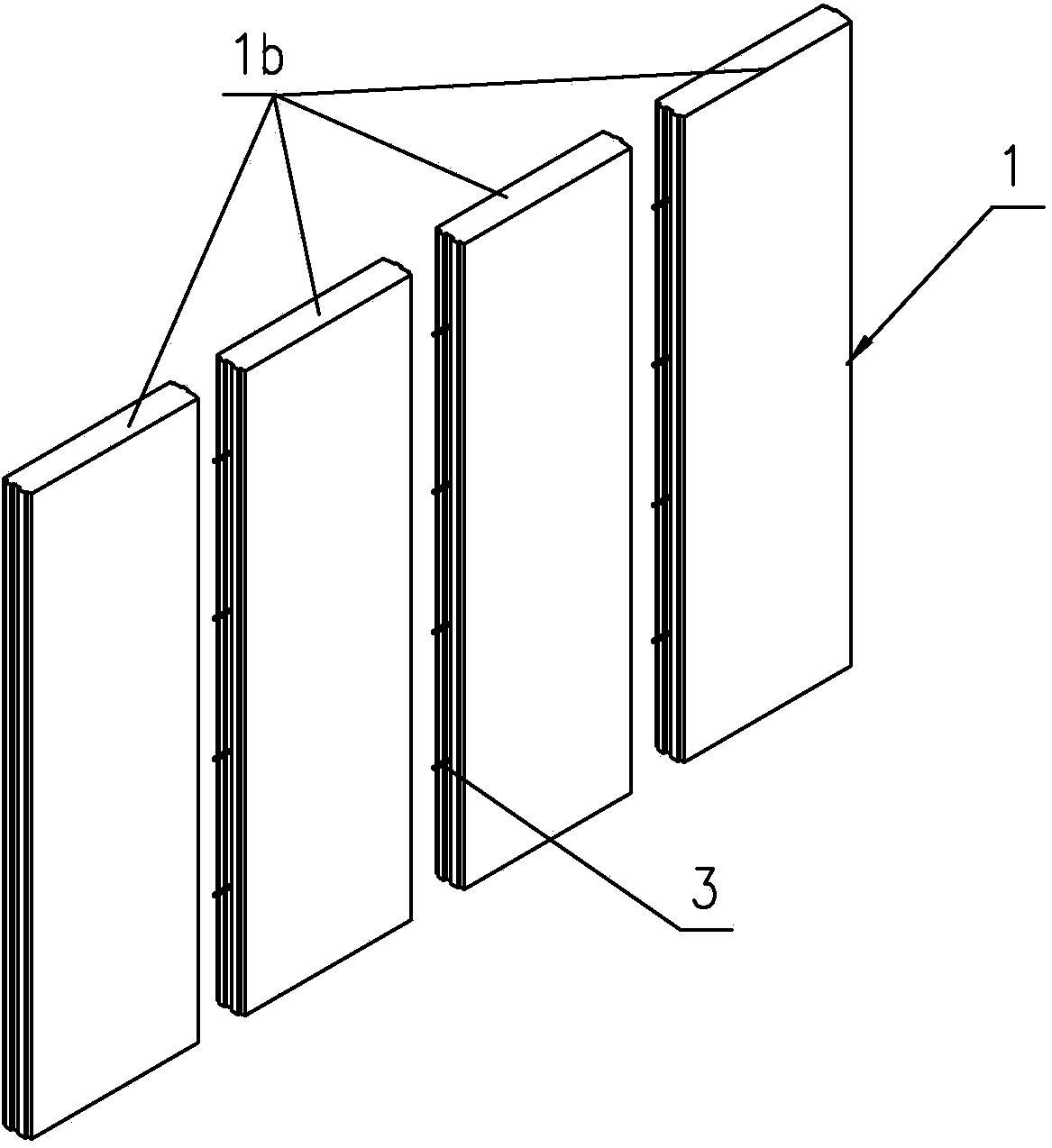

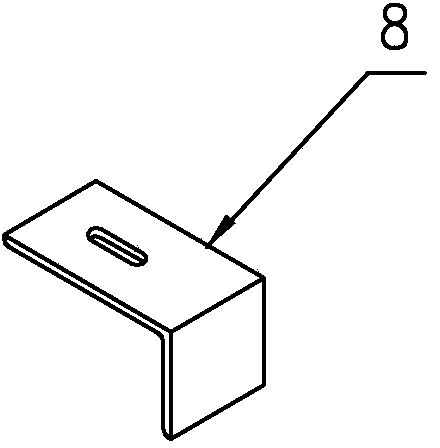

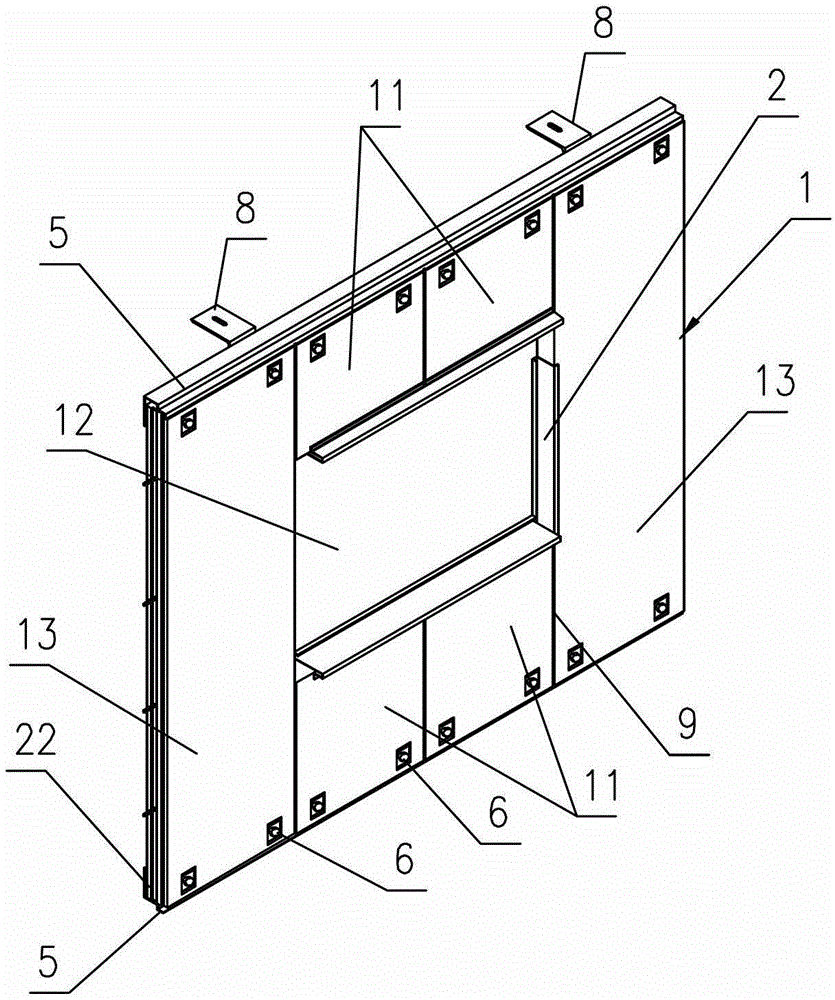

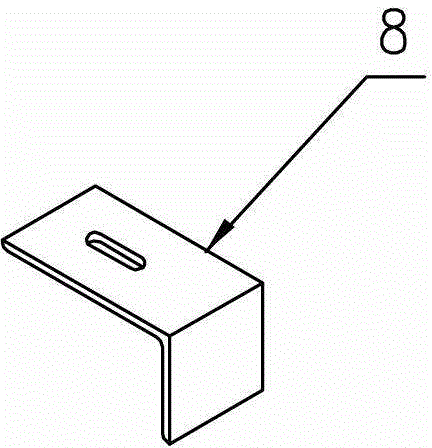

A kind of multifunctional combined lightweight concrete curtain wall and its making method

ActiveCN103374986BNo skeletonNo insulationWallsBuilding material handlingUltimate tensile strengthWeight light

The invention discloses a multifunctional combined lightweight concrete curtain wall and a constructing method thereof. The multifunctional combined lightweight concrete curtain wall is mainly composed of lightweight concrete board units along the outer surface of the main structure of a building. Each lightweight concrete board unit comprises at least two lightweight concrete boards which are horizontally arranged and spliced. A decorating surface is disposed on the outer surface of each lightweight concrete board. The upper end and lower end of each lightweight concrete board unit are respectively clamped into profile steel with a grooved cross section, and the profile steel located at the upper end of the lightweight concrete board unit is provided with hanging pieces for being connected with the main structure of the building. Gaps among the lightweight concrete boards and among the lightweight concrete board units are filled. The multifunctional combined lightweight concrete curtain wall based on self-structural-strength of the lightweight concrete boards and having the advantages of the lightweight concrete curtain walls has the advantages that structure and decoration are produced at one step in factories, construction garbage is few, noise pollution is reduced, safe and fast mounting is achieved, work efficiency is high, construction cost is lowered, and the multifunctional combined lightweight concrete curtain wall is widely applicable to building outer wall containment systems.

Owner:GUANGDONG HEYUAN LIANTIAN BUILDING INDZATION MFG

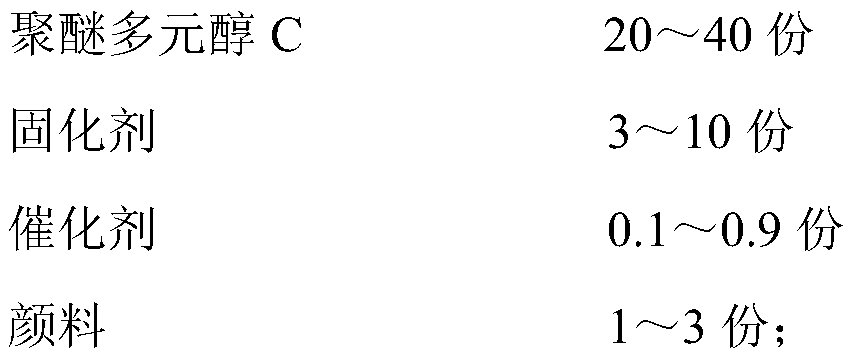

Polyurethane pedal pad for vehicles and preparation method of polyurethane pedal pad

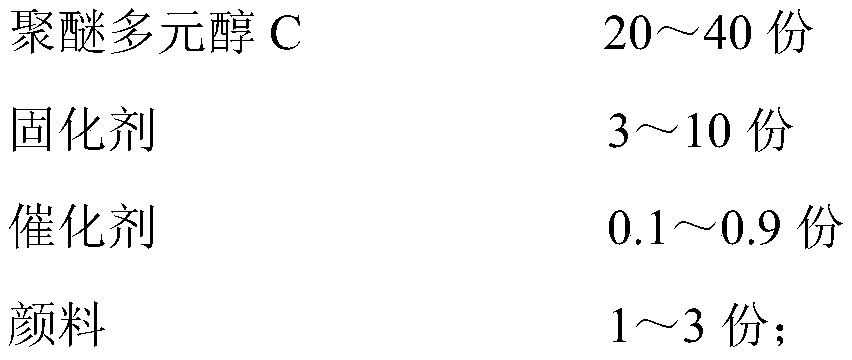

The invention relates to a polyurethane pedal pad for vehicles and a preparation method of the polyurethane pedal pad, and belongs to the technical field of polyurethane. The polyurethane pedal pad for the vehicles comprises a component A and a component B in a mass ratio of 100: 8-36, wherein (1), the component A is prepared from 30-80 parts of polyether polyol A, 20-70 parts of polyether polyolB and 15-85 parts of diphenylmethane-4,4'-diisocyanate; (2) the component B is prepared from 20-40 parts of polyether polyol C, 3-10 parts of a curing agent, 0.1-0.9 parts of a catalyst and 1-3 partsof pigment. The polyurethane pedal pad for the vehicles has the advantages of being good in elasticity, free of peculiar smell, waterproof, wear resistant, acid and alkali resistant, easy to clean, environmentally friendly and the like; the preparation method is simple and easy to implement.

Owner:耿佃勇

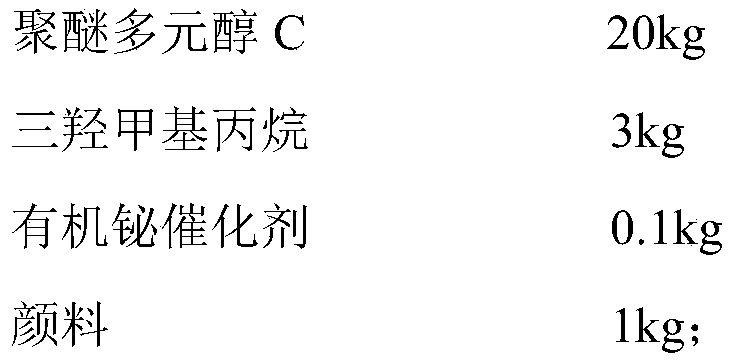

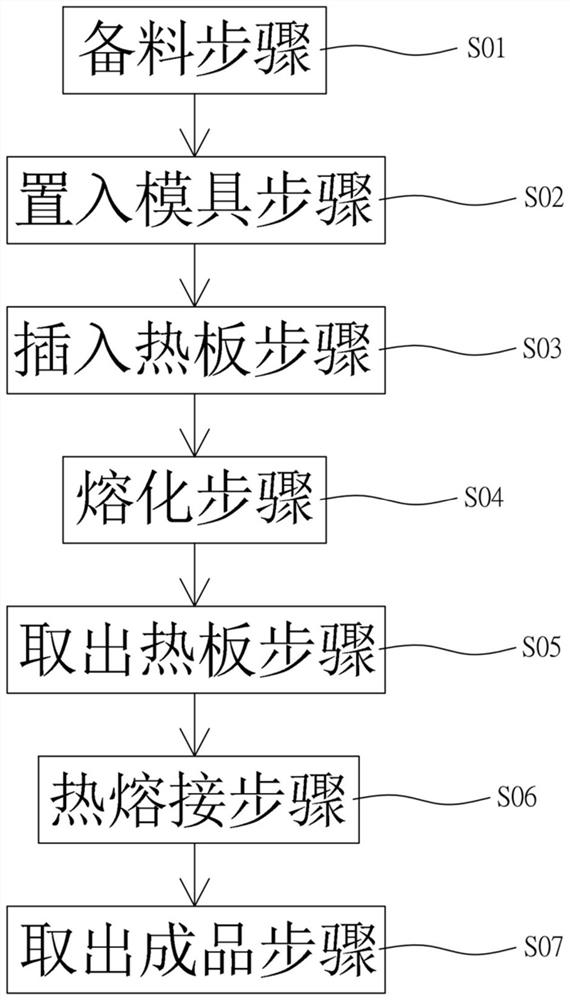

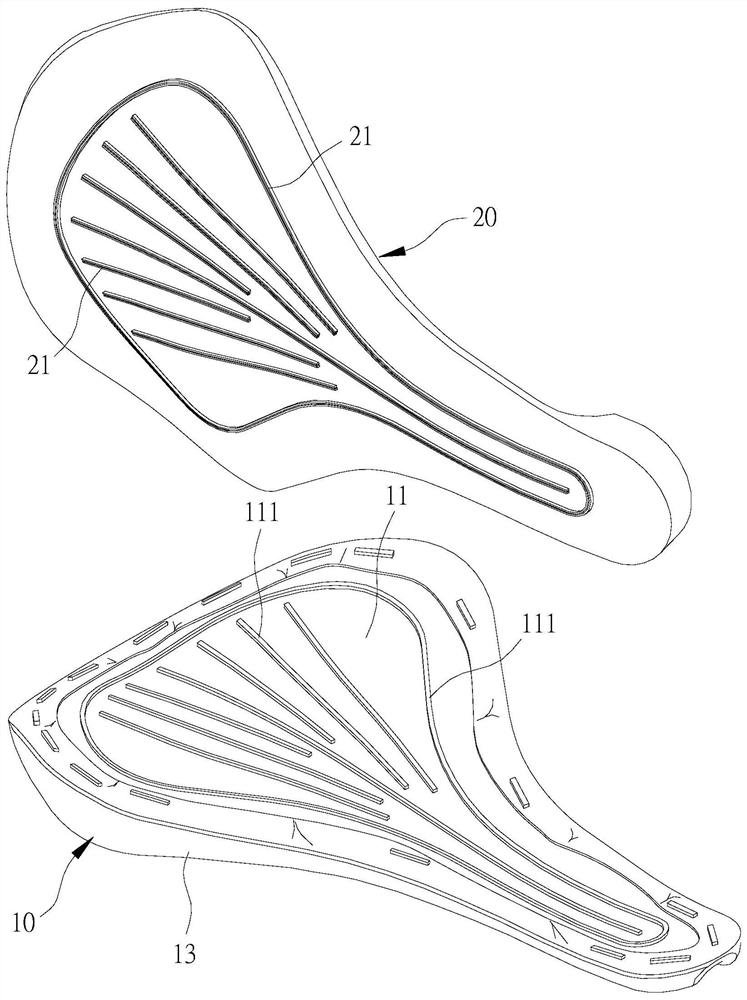

Integrated hot melting process of seat cushion

The invention provides an integrated hot melting process of a seat cushion. The integrated hot melting process comprises the following steps: a material preparation step: preparing a seat cushion body and a bottom shell layer; a mold placing step: placing the seat cushion body into a lower mold in an inverted manner, and placing the bottom shell layer into an upper mold in an inverted manner for adsorption; a hot plate inserting step: inserting a hot plate between the upper die and the lower die; a melting step: enabling the upper mold and the lower mold to be close to the hot plate, enabling the plurality of first hot melting line end surfaces and the plurality of second hot melting line end surfaces to be in contact with the hot plate, and melting into a molten state; taking out the hot plate: withdrawing the upper die and the lower die, and withdrawing the hot plate outwards; a hot melting step: the upper mold and the lower mold are closed, so that the rubber shell layer and the bottom shell layer are welded and combined into a whole through the plurality of first hot melting lines and the plurality of second hot melting lines; taking out a finished product: withdrawing the upper mold and the lower mold, and taking out the finished product; therefore, the attractiveness and the firmness of the seat cushion can be improved.

Owner:FOMING BICYCLE PARTS

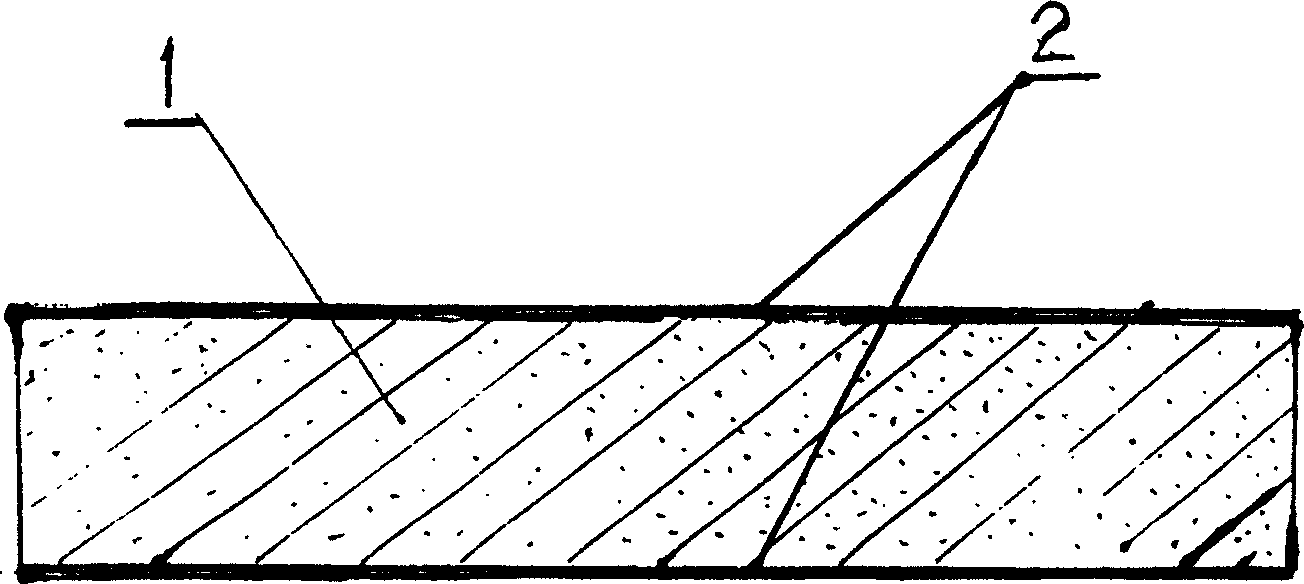

Nano sterilized health care board and producing method

InactiveCN1292898CStable physical and chemical propertiesNo flame retardantSynthetic resin layered productsWood layered productsNanometreIon

Owner:上海美连商务信息咨询服务有限公司

Fructus forsythiae volatile oil medical hydrocolloid dressing and preparation method thereof

InactiveCN101670126BGood hygroscopicityNon-irritatingAbsorbent padsBandagesPolymer scienceFoaming agent

The invention discloses a fructus forsythiae volatile oil medical hydrocolloid dressing that is formed by sticking two layers of materials, one layer of which is base mounting material, and the other layer is composed of the following components in terms of percentage by mass: 0.1%-10% of fructus forsythiae volatile oil, 1%-20% of water-soluble high polymer material, 10%-60% of rubber substrate, 0.01%-0.2% of antioxidant, 1%-9.7% of foaming agent and 0.1%-87.89% of water, wherein the total content of the above components is 100%. The method for preparing the dressing comprises the following steps of: first, adding a proper amount of water in water-soluble high polymer material so as to over-swelling the water-soluble high polymer material, then adding fructus forsythiae volatile oil to form I-phase solution, then adding antioxidant in the rubber substrate and evenly stirring to form II-phase solution, hybrid mixing I-phase solution and II-phase solution, adding foaming agent and rest water, fully stirring, transitively coating on the base mounting material, refrigerating and then unfreezing. The fructus forsythiae volatile oil medical hydrocolloid dressing has exact treatment effect, is safe and reliable, and has obviously economic benefits.

Owner:姚辉

Broad band radiation type leak coaxial cable for subway and its production method

ActiveCN101404350BUniform capacitanceNo corrosionCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsInsulation layerElectrical conductor

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

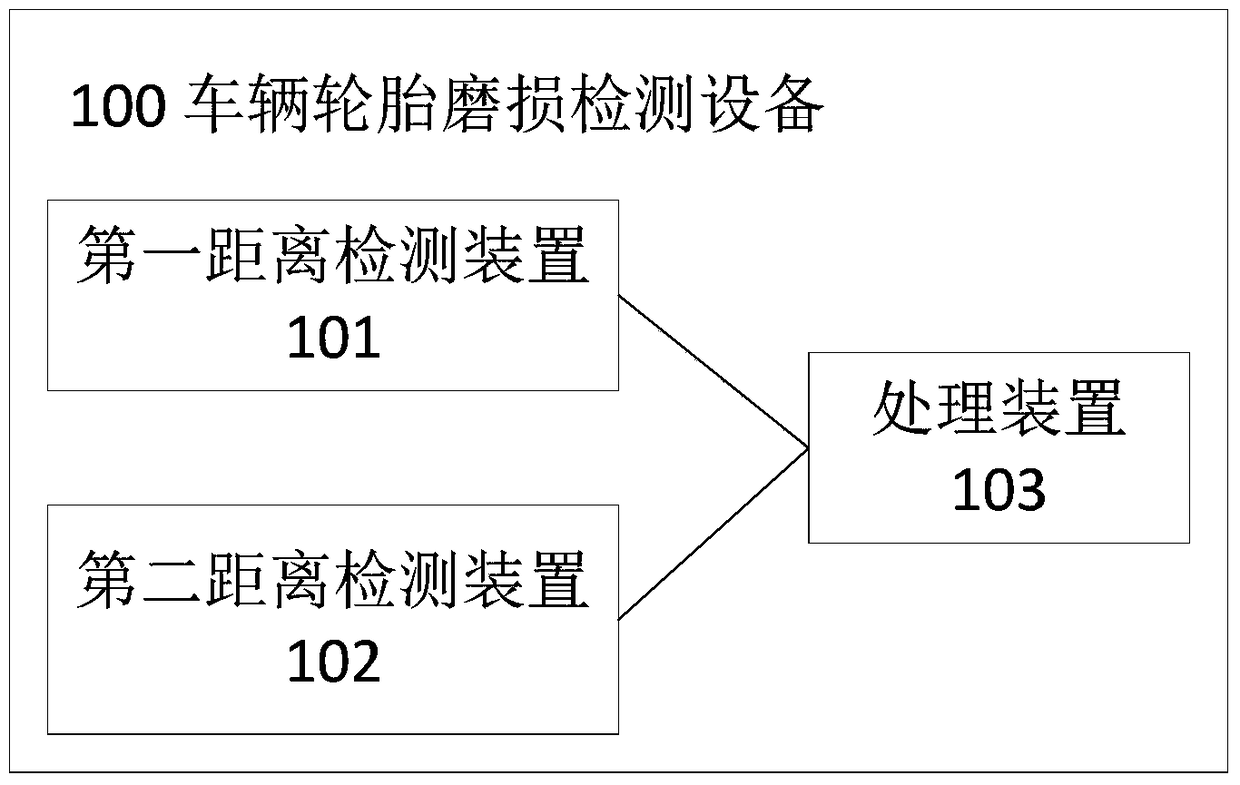

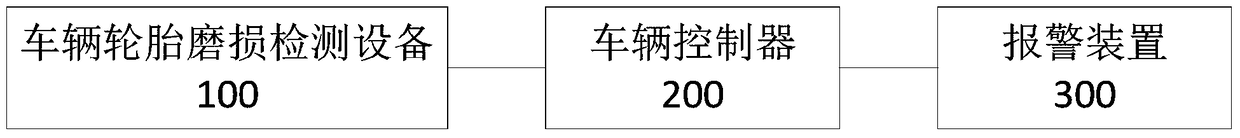

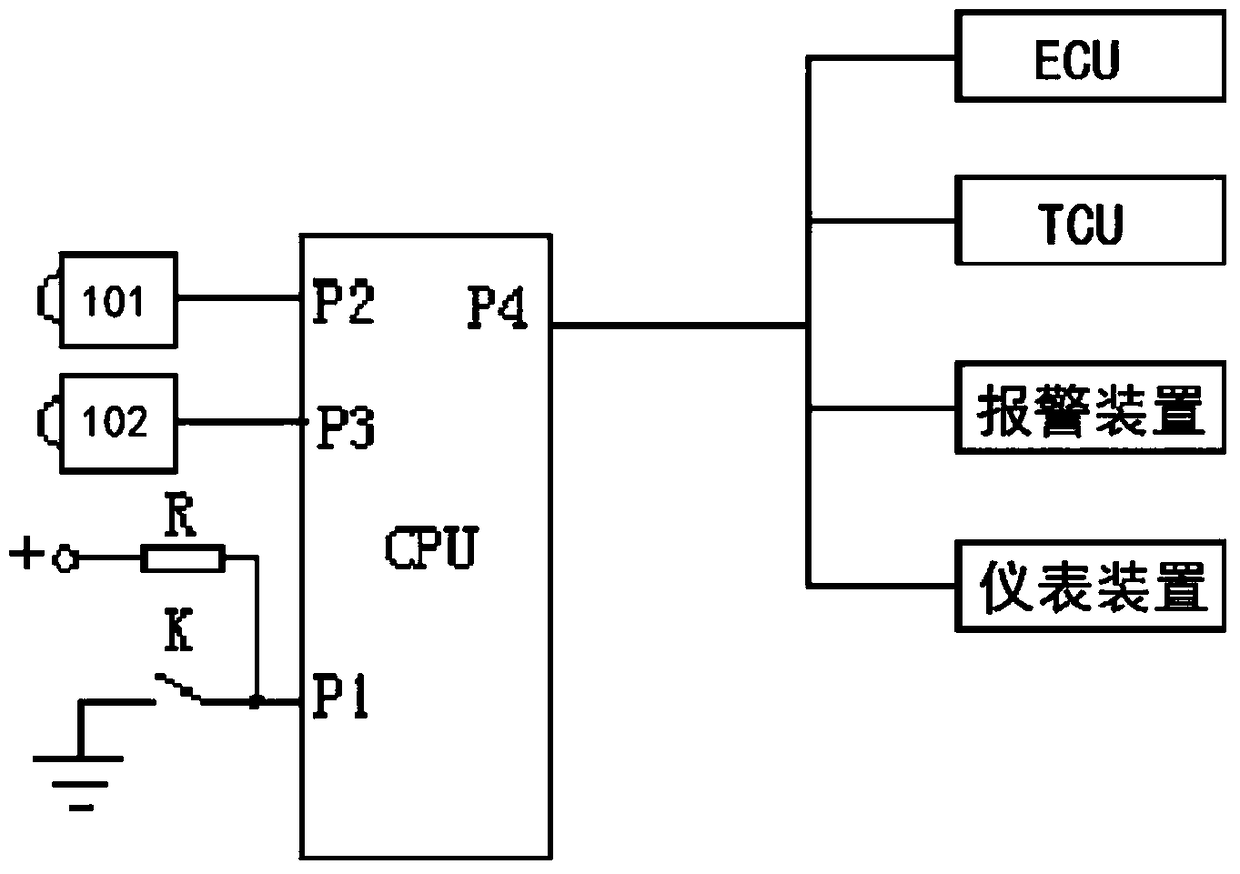

Vehicle tire wear detection device and method and vehicle control system

ActiveCN106626991BSolve the problem of uneven load around or even tire blowoutAvoid the impact of measurement accuracyTyre partsControl systemDistance detection

The invention relates to the field of vehicle tire wearing detection, and provides vehicle tire wearing detection equipment and a method and a vehicle control system. The vehicle tire wearing detection equipment comprises a first distance detection apparatus used for measuring the distance between tire and a wheel cover of the vehicle; a second distance detection apparatus used for measuring the distance between a suspension and a body of the vehicle; a processing apparatus wherein, the practical distance of the suspension and the tire is obtained according to the measured distance between the tire and the wheel cover under vehicle load, and the tire wear extent is calculated according to the practical distance between the suspension and the tire and the initial distance between the suspension and the tire under vehicle kerb mass; and an alarm apparatus used for alarming according to tire wear extent. The technical scheme of the vehicle tire wearing detection equipment is characterized in that under condition of no change of a tire structure, the vehicle tire wearing condition is automatically calculated, and driving safety can be guaranteed by controlling the driving speed according to the tire wear extent.

Owner:GREAT WALL MOTOR CO LTD

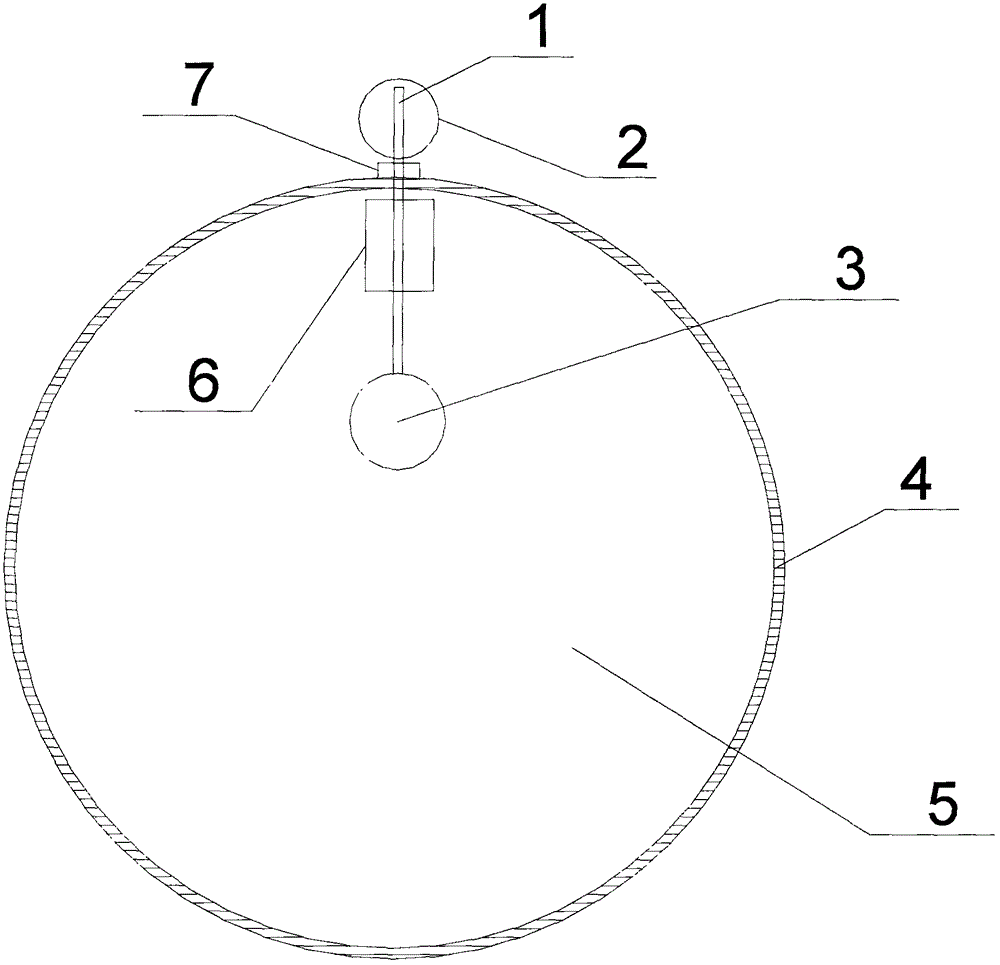

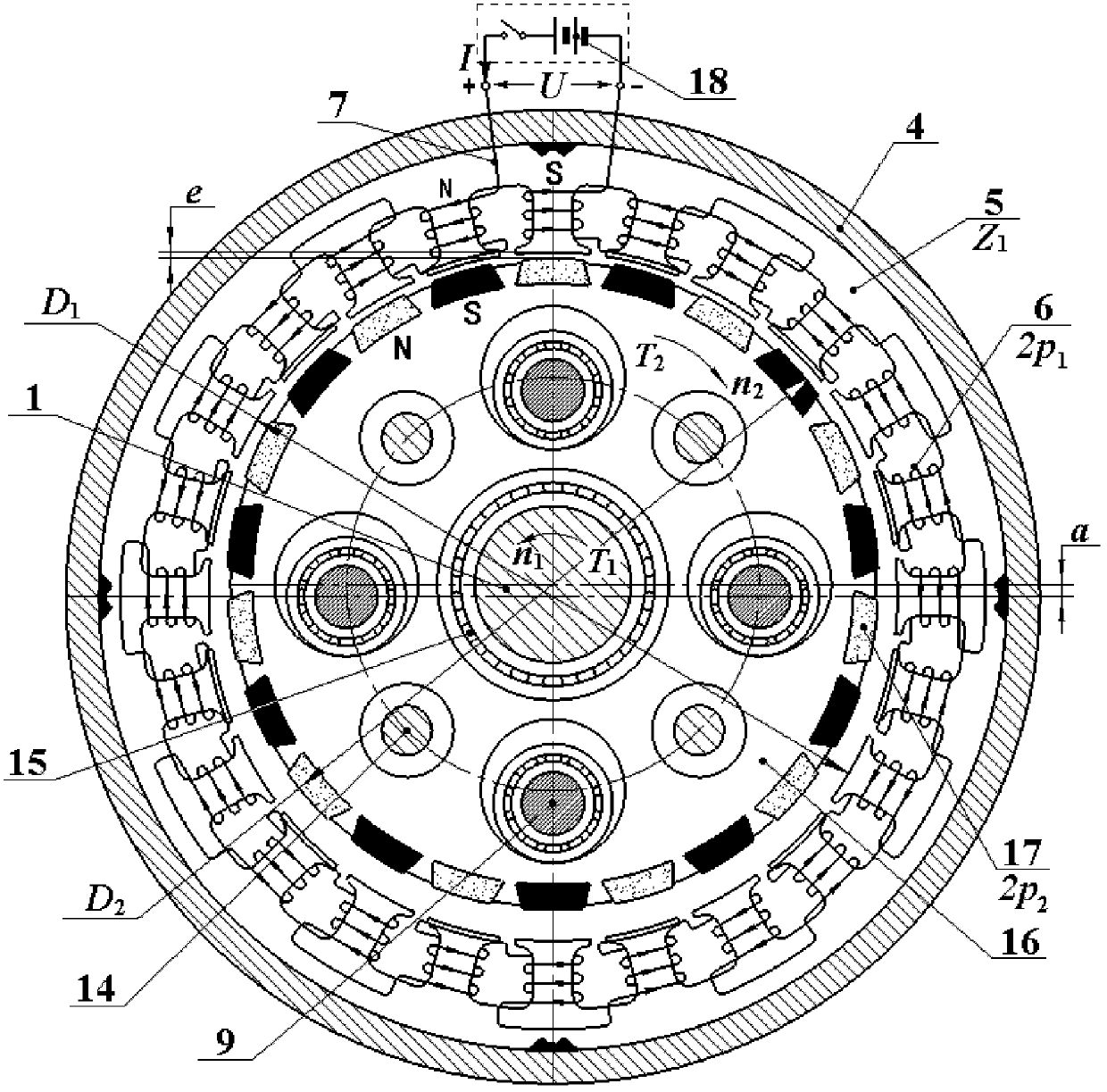

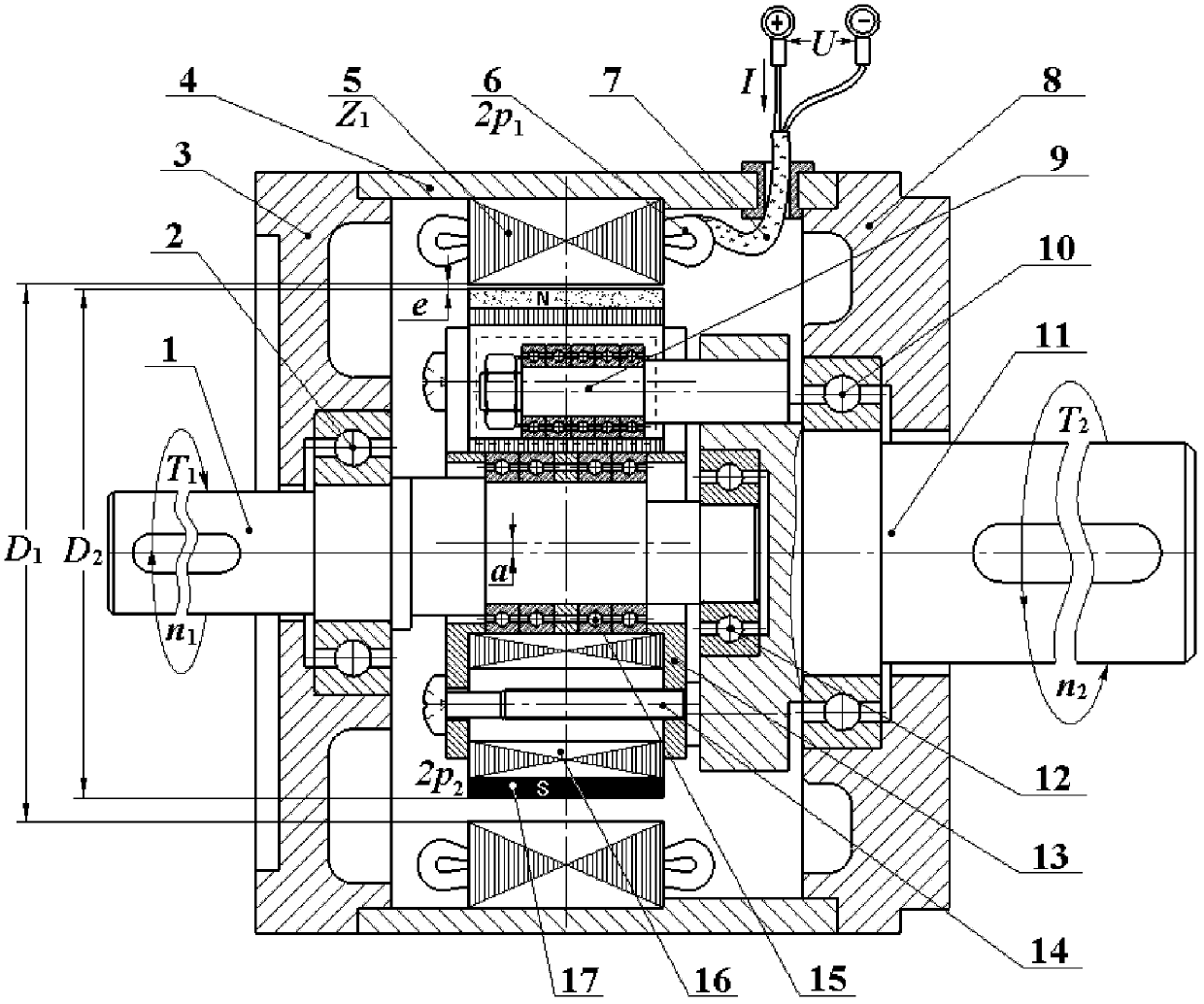

Small-range electromagnetic eccentric magnetic gear pair with novel radial magnetic field

InactiveCN102624196BEliminate contact frictionIn line with the characteristics of low-carbon environmental protection economyDynamo-electric gearsElectric machinesLow speedElectromagnetic field

Owner:余虹锦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com