Polyurethane pedal pad for vehicles and preparation method of polyurethane pedal pad

A polyurethane and foot pad technology, applied in the field of polyurethane, can solve the problems of insufficient environmental protection, difficult cleaning, poor wear resistance, etc., and achieve the effects of scientific and reasonable formula design, low cost, and simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The polyurethane foot pad for vehicles is composed of component A and component B, the mass ratio of component A and component B is 100:8, wherein:

[0033] (1) Component A is made up of the following raw materials in weight percentage:

[0034] Polyether polyol A 300kg

[0035] Polyether polyol B 20kg

[0036] Diphenylmethane diisocyanate 15kg;

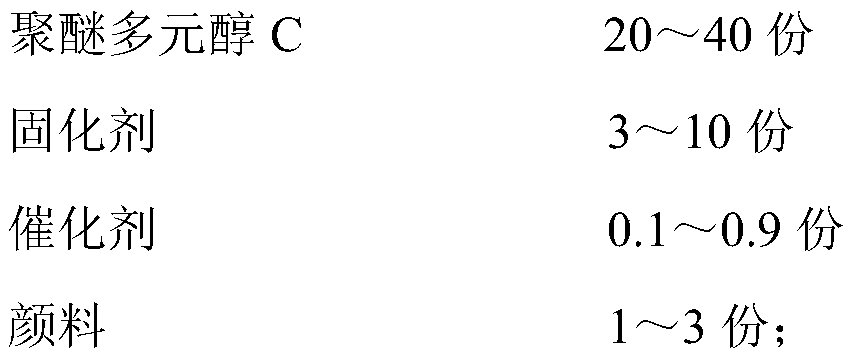

[0037] (2) B component is made up of the raw material of following percentage by weight:

[0038]

[0039] The polyether polyol A is DDL-8000D, produced by Zibo Dexin Federal Chemical Industry Co., Ltd. The products made of this polyether polyol have good elasticity and toughness.

[0040] The polyether polyol B is DMD-3000, produced by Zibo Dexin Federal Chemical Industry Co., Ltd. The products made of this polyether polyol have high hardness and wear resistance.

[0041] The polyether polyol C is DDL-400, produced by Zibo Dexin Federal Chemical Industry Co., Ltd., which acts as a chain extender.

[0042] The preparat...

Embodiment 2

[0047] The polyurethane foot pad for vehicles is composed of component A and component B, the mass ratio of component A and component B is 100:36, wherein:

[0048] (1) Component A is made up of the following raw materials in weight percentage:

[0049] Polyether polyol A 80kg

[0050] Polyether polyol B 70kg

[0051] Diphenylmethane diisocyanate 85kg;

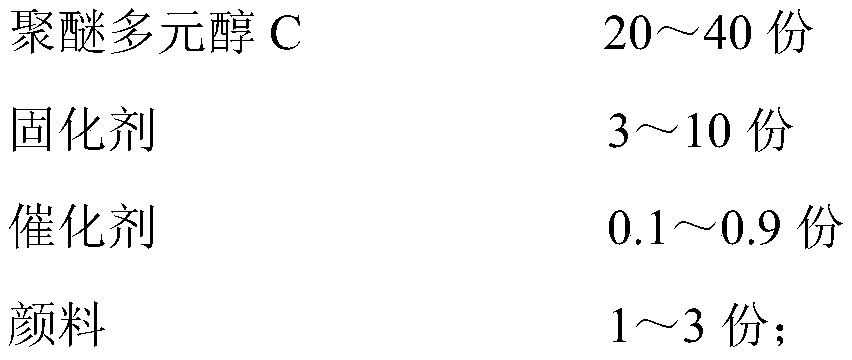

[0052] (2) B component is made up of the raw material of following percentage by weight:

[0053]

[0054] The polyether polyol A is DDL-8000D, produced by Zibo Dexin Federal Chemical Industry Co., Ltd. The products made of this polyether polyol have good elasticity and toughness.

[0055] The polyether polyol B is DMD-3000, produced by Zibo Dexin Federal Chemical Industry Co., Ltd. The products made of this polyether polyol have high hardness and wear resistance.

[0056] The polyether polyol C is DDL-400, produced by Zibo Dexin Federal Chemical Industry Co., Ltd., which acts as a chain extender.

[0057] The preparat...

Embodiment 3

[0062] The polyurethane foot pad for vehicle is composed of component A and component B, the mass ratio of component A and component B is 100:25, wherein:

[0063] (1) Component A is made up of the following raw materials in weight percentage:

[0064] Polyether polyol A 50kg

[0065] Polyether polyol B 50kg

[0066] Diphenylmethane diisocyanate 35kg;

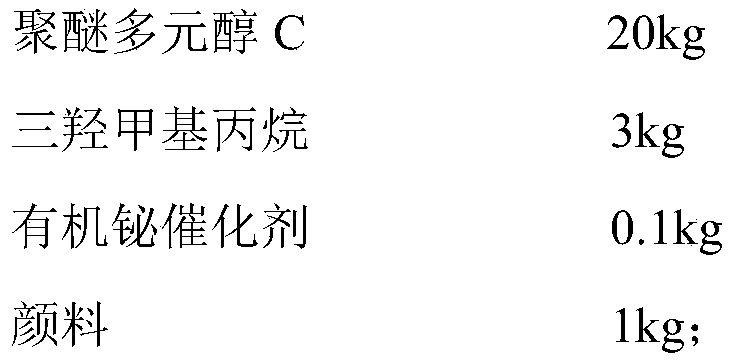

[0067] (2) B component is made up of the raw material of following percentage by weight:

[0068]

[0069] The polyether polyol A is DDL-8000D, produced by Zibo Dexin Federal Chemical Industry Co., Ltd. The products made of this polyether polyol have good elasticity and toughness.

[0070] The polyether polyol B is DMD-3000, produced by Zibo Dexin Federal Chemical Industry Co., Ltd. The products made of this polyether polyol have high hardness and wear resistance.

[0071] The polyether polyol C is DDL-400, produced by Zibo Dexin Federal Chemical Industry Co., Ltd., which acts as a chain extender.

[0072] The preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com