Ultra-high molecular weight polyacrylamide composite initiator and method for preparing ultra-high molecular weight polyacrylamide by using same

A polyacrylamide and ultra-high molecular weight technology, applied in the field of ultra-high molecular weight polyacrylamide, can solve the problems of low molecular weight of ultra-high molecular weight polyacrylamide, achieve scientific and reasonable formula design, simple and easy preparation method, improve molecular weight and The effect of solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

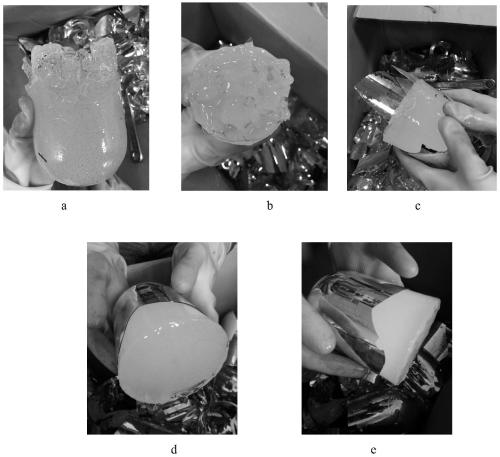

Image

Examples

Embodiment 1

[0039] A composite initiator, made of the following raw materials in mass percentage: 20% of tetramethylethylenediamine, 10% of N,N dimethyl-p-toluidine, 20% of β-2-methylpropionitrile, three Ethylene glycol amine 5%, cetyl alcohol 3%, water 42%.

[0040] Utilize above compound initiator to prepare the method for ultrahigh molecular weight polyacrylamide, specifically comprise the following steps:

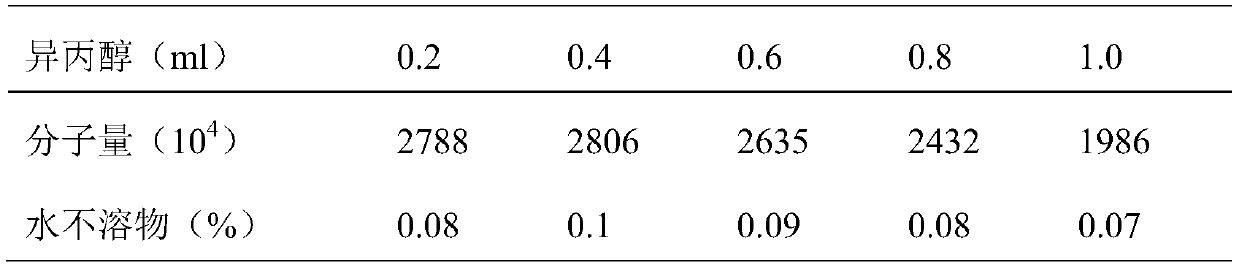

[0041] (1) Add acrylamide monomer to the polymerization kettle, then add water, then add 0.02% isopropanol, 5% urea, and 0.001% thiourea in sequence, measure according to the mass of acrylamide monomer, stir, and adjust the pH at 7.75 ;

[0042] (2) The reaction temperature of the system is controlled at 1 ± 0.5 ° C, and then nitrogen is introduced to control the nitrogen pressure to remain at 0.2 MPa; after 15 minutes, 0.2% of the composite initiator and 0.004% of sulfurous acid are added at intervals of 5 minutes. Sodium hydrogen and 0.005% potassium persulfate, measured by the...

Embodiment 2

[0046] A composite initiator, made of the following raw materials in mass percentage: 30% of tetramethylethylenediamine, 20% of N,N dimethyl-p-toluidine, 10% of β-2-methylpropionitrile, three Ethylene glycol amine 10%, cetyl alcohol 5%, water 25%.

[0047] Utilize above compound initiator to prepare the method for ultrahigh molecular weight polyacrylamide, specifically comprise the following steps:

[0048] (1) Add acrylamide monomer to the polymerization kettle, then add water, then add 0.03% isopropanol, 10% urea, and 0.003% thiourea in sequence, measure according to the mass of acrylamide monomer, stir, and adjust the pH at 7.95 ;

[0049] (2) The reaction temperature of the system is controlled at 1 ± 0.5°C, and then nitrogen is introduced to control the nitrogen pressure to remain at 0.3MPa; after 15 minutes, 0.4% of the composite initiator and 0.005% of sulfurous acid are added at intervals of 5 minutes respectively Sodium hydrogen and 0.007% potassium persulfate, meas...

Embodiment 3

[0053] A composite initiator, made of the following raw materials in mass percentage: 10% of tetramethylethylenediamine, 5% of N,N dimethyl-p-toluidine, 20% of β-2-methylpropionitrile, three Ethylene glycol amine 10%, cetyl alcohol 5%, water 50%.

[0054] Utilize above compound initiator to prepare the method for ultrahigh molecular weight polyacrylamide, specifically comprise the following steps:

[0055] (1) Add acrylamide monomer to the polymerization kettle, then add water, then add 0.025% isopropanol, 8% urea, and 0.002% thiourea in sequence, measure according to the mass of acrylamide monomer, stir, and adjust the pH at 7.80 ;

[0056] (2) The reaction temperature of the system is controlled at 1 ± 0.5 ° C, and then nitrogen is introduced to control the nitrogen pressure to remain at 0.2 MPa; after 15 minutes, 0.3% of the composite initiator and 0.004% of sulfurous acid are added at intervals of 5 minutes. Sodium hydrogen and 0.006% potassium persulfate, measured by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com