LED coating for encapsulating quantum dots by multiple layers and preparation method thereof

A technology of quantum dots and packaging material layers, applied in luminescent coatings, electrical components, circuits, etc., can solve the problems of strong absorption, quenching of quantum dots, poor stability of quantum dots, etc., to improve utilization efficiency, simplify control procedures, realize The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below.

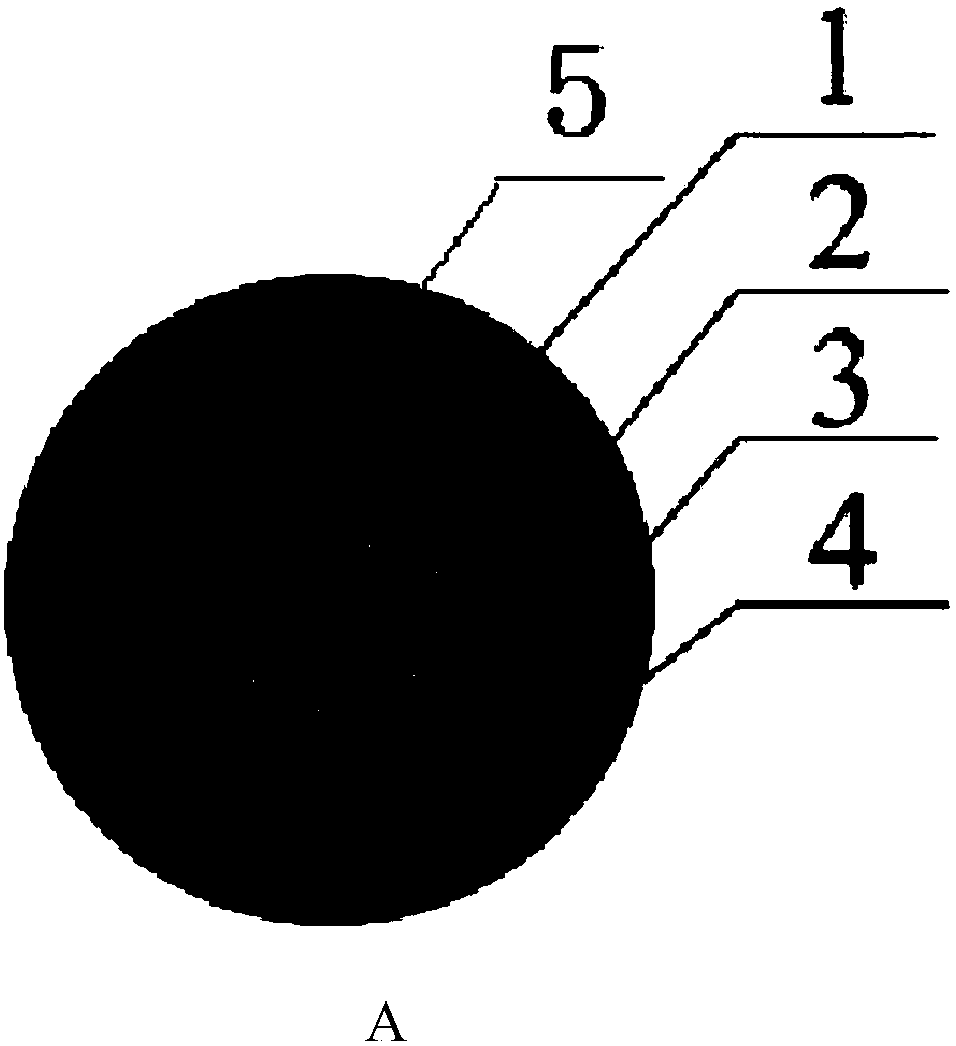

[0034] like figure 1 , figure 2 As shown, a kind of LED coating of multi-layer encapsulation quantum dot, comprises traditional encapsulation material layer 4 and the encapsulation particle 6 of several quantum dots and scattering particle scattered in the traditional encapsulation material layer 4, the quantum dot and the encapsulation particle 6 of scattering particle The encapsulating particle 6 includes quantum dots 1 , a compatible polymer layer 2 and a water-oxygen barrier film layer 3 sequentially from inside to outside, and a number of inorganic nano-scattering particles 5 are scattered and distributed in the compatible polymer layer 2 .

[0035] The material of the compatible polymer layer 2 is any one or a combination of polymethyl methacrylate, hydrogenated styrene-butadiene-styrene block copolymer, polyvinylidene fluoride, and polystyrene . The material of the water and oxygen barrier fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com