3D printing gypsum powder and preparation method thereof

A 3D printing and gypsum powder technology, which is applied in the field of 3D printing gypsum powder and its preparation, can solve the problems of uneven powder spreading of printers, poor fluidity of gypsum powder, and rough surface of products, so as to achieve smooth surface, no concave-convex pits, easy molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Wherein, the preparation method of modified toughening fiber comprises the following steps:

[0052] S1 pretreatment: Dissolve the surface modifier in absolute ethanol, and then spray it on the surface of SF in the form of spray. After the ethanol volatilizes, put it in an oven and dry it at 107°C for 4 hours. Put the resin PLA and PBS in the oven Dry at 83°C for 2 hours; the surface modifier is stearic acid, and the mass ratio of the surface modifier, SF, PLA, and PBS is 1:85:15:5;

[0053] S2 Mixing: mix the pretreated components, add them to the torque rheometer and melt mix; the mixing conditions are: mixing temperature 190°C, mixing speed 30r / min, mixing time 8min;

[0054] S3 Compression Molding: Press the mixed materials that have been compacted into semi-finished boards on a flat vulcanizing machine; the molding conditions are: molding temperature 185 ° C, molding pressure 10 MPa, molding time 6 minutes, cooling time 5 minutes;

[0055] S4 shredding: shredding ...

Embodiment 1

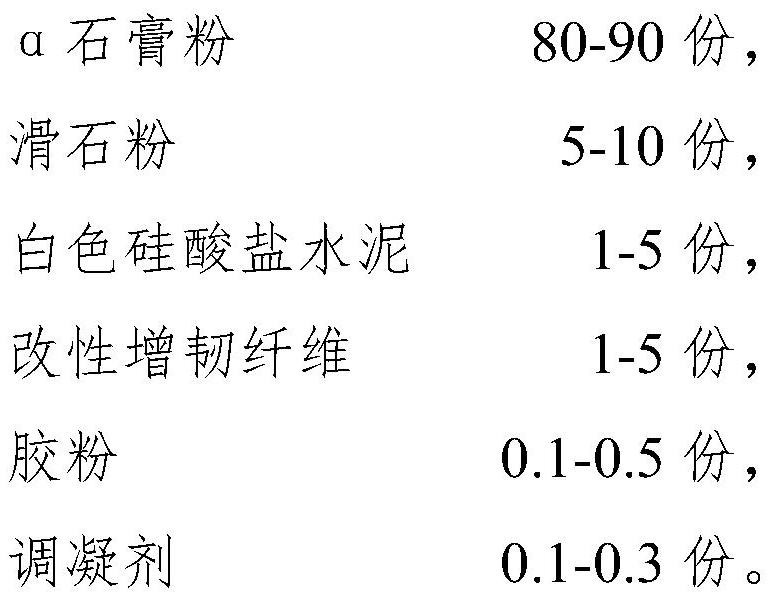

[0059] A kind of 3D printing gypsum powder, the 3D printing gypsum powder includes the following components in parts by mass:

[0060] 80 parts of α gypsum powder,

[0061] Talcum powder 10 parts,

[0062] 1 part of white Portland cement,

[0063] Modified toughening fiber 5 parts,

[0064] 0.1 parts of rubber powder,

[0065] Coagulant regulator 0.3 parts.

Embodiment 2

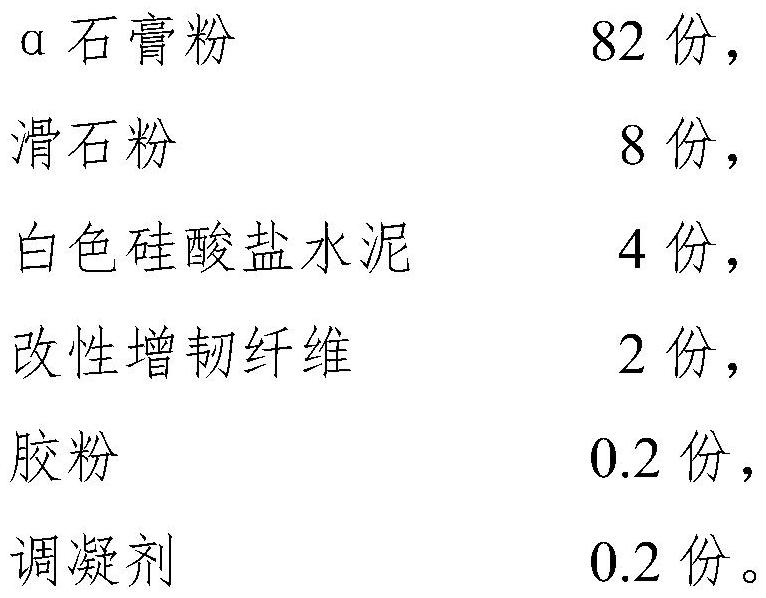

[0067] A kind of 3D printing gypsum powder, the 3D printing gypsum powder includes the following components in parts by mass:

[0068] 82 parts of α gypsum powder,

[0069] 8 parts talcum powder,

[0070] 4 parts of white Portland cement,

[0071]Modified toughening fiber 2 parts,

[0072] 0.2 parts of rubber powder,

[0073] Coagulant regulator 0.2 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com