Broad band radiation type leak coaxial cable for subway and its production method

A leaky coaxial cable, radiation type technology, used in the manufacture of coaxial cables, coaxial cables/analog cables, insulated cables, etc., can solve the problems of incomplete coverage, the antenna gain cannot reach the field strength coverage, and the size of the antenna is limited. , to achieve the effect of uniform coverage field strength, good sealing, and wide operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

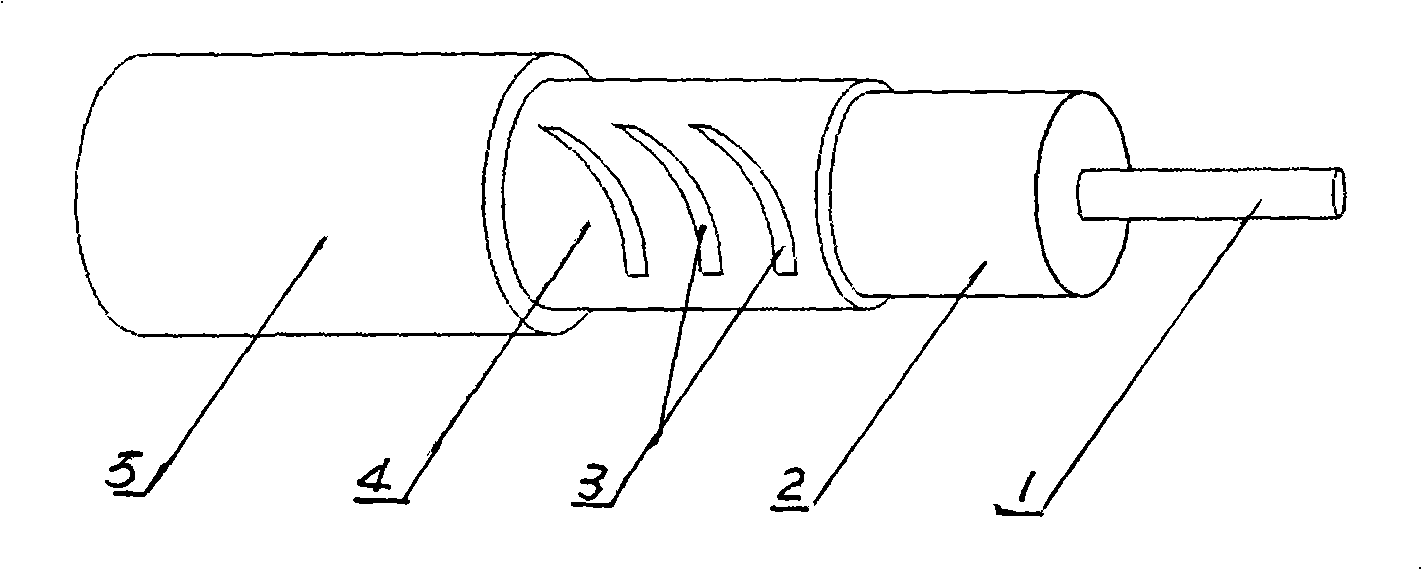

[0026] 1. A copper strip with a thickness of 0.3mm is selected and welded longitudinally to form a copper tube, and then the corrugated inner conductor 1 with an outer diameter of Φ17.4±0.1mm is manufactured by embossing;

[0027] 2. Nitrogen or carbon dioxide with a purity of 99.99% is injected into the molten polyethylene insulator through a high pressure of 350bar, fully mixed at a high temperature of 180°C, and physically foamed, and then extruded and coated on the surface of the inner conductor 1 The insulating layer 2 is formed, the insulating layer 1 has uniform foaming pores, and the foaming pores are closed to each other, the outer diameter of the foamed cable core is uniform and consistent, the foaming degree reaches 80%, and the capacitance is stably controlled within the range of 77±1pF / m Inside;

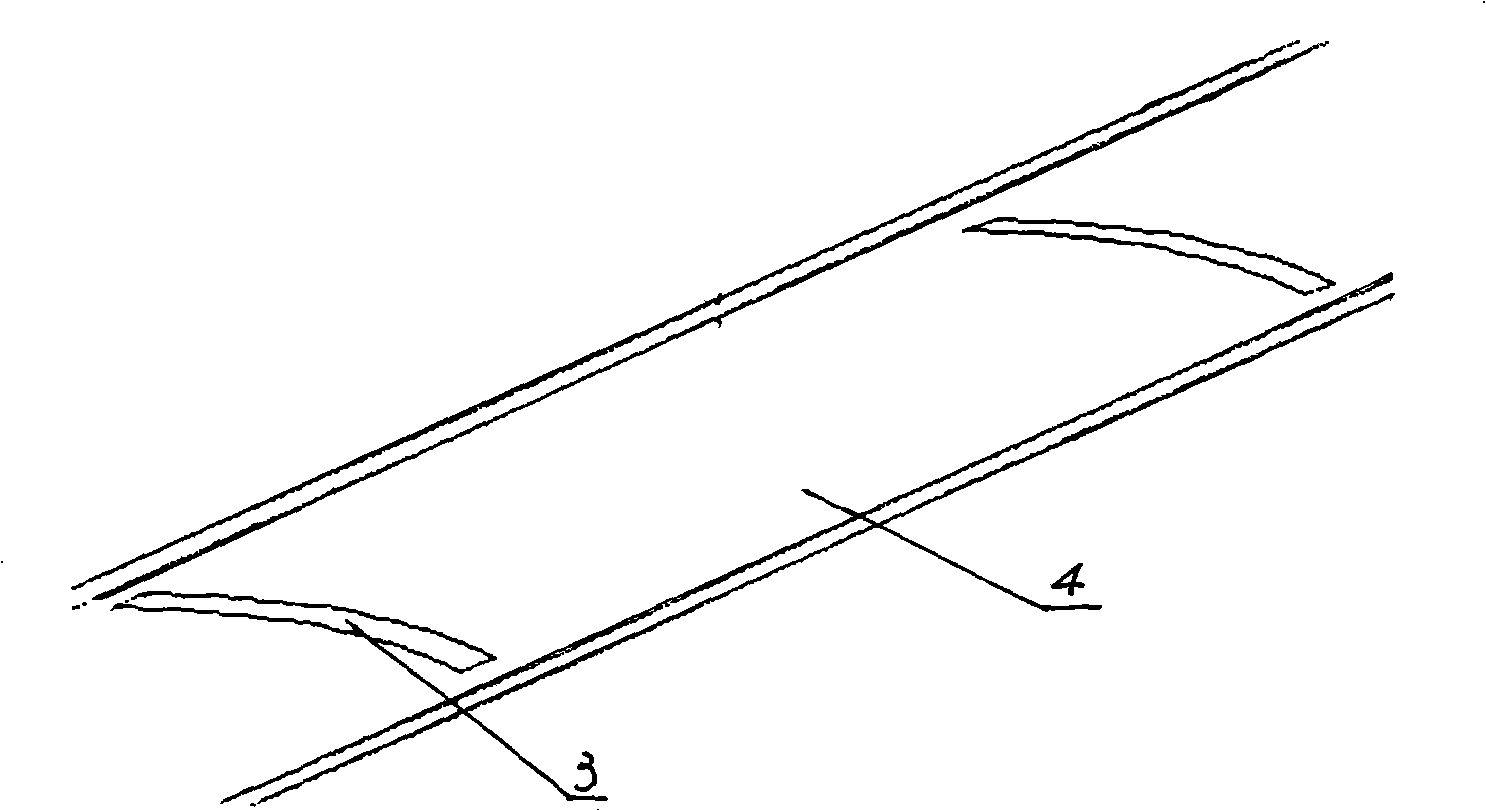

[0028] 3. The outer conductor 4 uses a copper foil strip. First, the copper foil strip is programmed and continuously automatically controlled on a special punching mach...

Embodiment 2

[0031] 1. A copper strip with a thickness of 0.35mm is selected and welded longitudinally to form a copper pipe embossed and integrated to manufacture a spiral corrugated inner conductor 1 with an outer diameter of Φ17.4±0.1mm;

[0032] 2. Nitrogen or carbon dioxide with a purity of 99.99% is injected into the molten polyethylene insulator through a high pressure of 350bar, fully mixed at a high temperature of 190°C, and physically foamed, and then extruded and coated on the surface of the inner conductor 1 The insulating layer 2 is formed, the insulating layer 1 has uniform foaming pores, and the foaming pores are closed to each other, the outer diameter of the foamed cable core is uniform and consistent, the foaming degree reaches 80%, and the capacitance is stably controlled within the range of 77±1pF / m Inside;

[0033] 3. The outer conductor 4 uses a copper foil strip. First, the copper foil strip is programmed and continuously automatically controlled on a special punchin...

Embodiment 3

[0036] 1. A copper strip with a thickness of 0.4mm is selected and welded longitudinally to form a copper tube embossed and integrated to manufacture a spiral corrugated inner conductor 1 with an outer diameter of Φ17.4±0.1mm;

[0037]2. Nitrogen or carbon dioxide with a purity of 99.99% is injected into the molten polyethylene insulator through a high pressure of 350bar, fully mixed at a high temperature of 200°C, and physically foamed, and then extruded and coated on the surface of the inner conductor 1 The insulating layer 2 is formed, the insulating layer 1 has uniform foaming pores, and the foaming pores are closed to each other, the outer diameter of the foamed cable core is uniform and consistent, the foaming degree reaches 80%, and the capacitance is stably controlled within the range of 77±1pF / m Inside;

[0038] 3. The outer conductor 4 uses a copper foil strip. First, the copper foil strip is programmed and continuously automatically controlled on a special punching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com