A preparing method of aliphatic/aromatic copolyester

A technology of aromatic and copolyester, which is applied in the field of copolyester synthesis and preparation, can solve the problems of restricting the scale-up industrial production of biodegradable aliphatic-aromatic copolyester, not suitable for continuous production, waste of manpower and material resources, etc. , to achieve the effect of streamlining equipment, less addition amount and improving reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

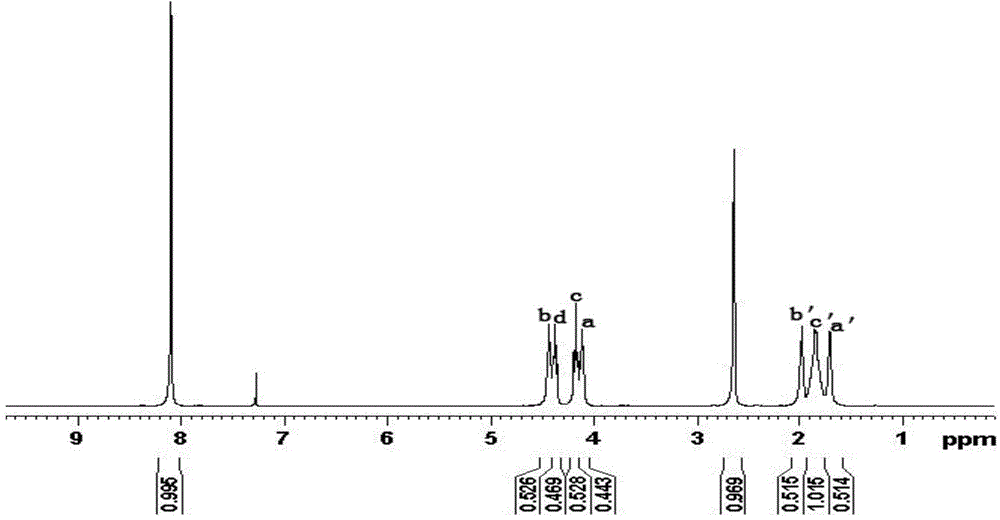

Method used

Image

Examples

Embodiment 1~5

[0032] 1) Esterification: Add 70.63g (0.425mol) terephthalic acid, 55g (0.466mol) succinic acid (0.466mol), 108.3g (1.20mol) 1,4-butanediol into a 500ml three-neck flask, and add titanium catalyst at the same time C-94 (provided by Sachtleben, Germany) and synergistic catalyst (provided by Shanghai Sinopharm Group, see Table 2), nitrogen protection, stirring and heating, the reaction temperature is controlled at 150-230 ° C, the esterification water is collected, and the end is completed after 2.5 hours reaction;

[0033]2) Prepolymerization: After the reaction is finished, the system is slowly evacuated, the vacuum degree is 200-300Pa, the temperature is 230-250℃, and the duration is 1-2 hours;

[0034] 3) Polycondensation: Then apply a high vacuum, the vacuum degree is ≤100pa, the temperature is 240-260°C, and the duration is 3-5h. The white product is aliphatic / aromatic copolyester.

[0035] The reaction conditions of each step of Examples 1-5 are shown in Table 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com