Heterogeneous catalyst and application of same to preparation of polyester

A kind of heterogeneous catalyst, catalyst technology, applied in the field of polyester preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

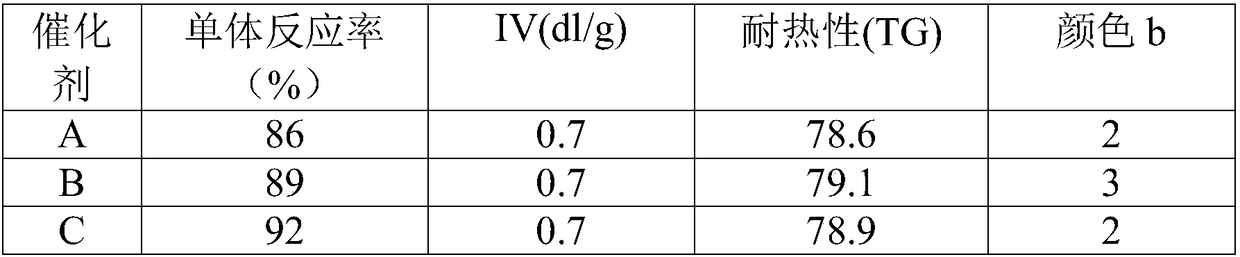

Embodiment 1

[0031] Catalyst A preparation

[0032] The preparation of described catalyst A can operate according to the following steps:

[0033] First, add 100mL of methanol, 10mL of ammonia water with a mass fraction of 28% and 30mL of deionized water into a 250mL three-necked flask, stir mechanically for 30 minutes, and then add 4.2g of ethyl orthosilicate dropwise into it, and stir at 60°C for 3 hours , after centrifuging and washing with water and drying, the catalyst SiO 2 Silicon spheres.

[0034] Take 2g of prepared SiO 2 Suspend the silicon spheres in 20 mL of absolute ethanol, add 2 mL of polyethylene glycol 200 as a dispersant, and add 0.32 g of BiCl under stirring conditions 3 with 0.095gTiCl 4 (BiCl 3 with TiCl 4 The molar ratio is about 2:1) and mix evenly, slowly add ammonia water with a mass fraction of 28% under stirring to adjust the pH to 5, age at room temperature for 6 hours, filter and dry, and calcinate at 500°C for 4 hours.

[0035] Suspend 2 g of calcined s...

Embodiment 2

[0037] Catalyst B preparation

[0038] The preparation method of catalyst B is the same as that of catalyst A in Example 1, except that the BiCl used 3 with TiCl 4 The molar ratio is about 1:1.

Embodiment 3

[0040]Catalyst C Preparation

[0041] The preparation method of catalyst C is the same as that of catalyst A in Example 1, except that the BiCl used 3 with TiCl 4 The molar ratio is about 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com