Preparation method for cold-resistant plasticizer dioctyl sebacate

A technology of dioctyl sebacate and cold-resistant plasticizer, which is applied in the field of preparation of PVC additives, can solve the problems of low product yield and purity, long esterification reaction time, and incomplete catalytic reaction, etc. The effect of esterification reaction time, reduction of water consumption and sewage discharge, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

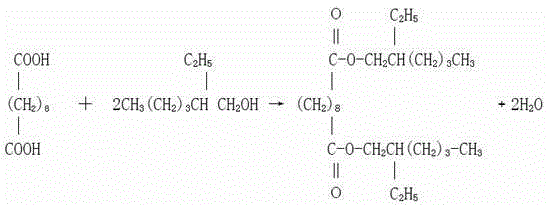

Image

Examples

specific Embodiment 1

[0028] A kind of preparation method of cold-resistant plasticizer dioctyl sebacate described in the present embodiment, comprises the following steps:

[0029] Step 1, esterification reaction process

[0030] Add 2940 kilograms of 2-ethylhexanol and 1200 kilograms of sebacic acid into 6m by mass ratio 2.45:1.0 3 In the esterification reaction kettle, the temperature was raised to 150°C while stirring, 5.0 kg of tetraisopropyl titanate was added, and the temperature was raised to 215°C. After 3.5 hours of reaction, samples were taken, and the acid value of the reaction product was measured to be 0.185 mgKOH / g .

[0031] Step 2, dealcoholization process

[0032] After the esterification reaction is complete, dealcoholize under normal pressure for 1 hour at 190°C to remove 1200 kg of excess alcohol, and then dealcoholize in vacuum for 30 minutes at a vacuum degree of -0.085 to -0.075MPa to remove excess alcohol and 162 kg of partial esters, the acid value of the detected produ...

specific Embodiment 2

[0041] A kind of preparation method of cold-resistant plasticizer dioctyl sebacate described in the present embodiment, comprises the following steps:

[0042] Step 1, esterification reaction process

[0043] According to the ratio of mass ratio 2.5:1.0, put 2800 kg of 2-ethylhexanol and 1120 kg of sebacic acid into 6m 3 In the esterification reaction kettle, the temperature was raised to 160°C while stirring, 4.8 kg of butyl phthalate was added, and the temperature was raised to 220°C to carry out the esterification reaction; after 3 hours, a sample was taken, and the acid value of the product was measured to be 0.178mgKOH / g .

[0044] Step 2, dealcoholization process

[0045] After the esterification reaction is completed, dealcoholize under normal pressure at 205°C for 1 hour to remove 1150 kg of excess alcohol, and then dealcoholize in vacuum for 40 minutes at a vacuum degree of -0.090 to -0.080 MPa to remove excess alcohol and 172 kg of partial esters; the acid value of ...

specific Embodiment 3

[0054] A kind of preparation method of cold-resistant plasticizer dioctyl sebacate described in the present embodiment, comprises the following steps:

[0055] Step 1, esterification reaction process

[0056] According to the mass ratio of 2.6:1.0, put 2990 kg of 2-ethylhexanol and 1150 kg of sebacic acid into the esterification reaction kettle, heat up to 155 °C while stirring, add 4.6 kg of tetramethyl titanate, and heat up After the esterification reaction was carried out at 225° C. for 4.0 hours, a sample was taken, and the acid value of the product was measured to be 0.186 mgKOH / .

[0057] Step 2, dealcoholization process

[0058] After the esterification reaction is completed, dealcoholize under normal pressure for 1 hour and 20 minutes at 200°C to remove 1,260 kg of excess alcohol, and then use vacuum dealcoholization for 40 minutes at a vacuum degree of -0.090 to -0.080 MPa to remove excess alcohol. 220 kg of alcohols and some esters; the acid value of the tested pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com