Polyformaldehyde composite low in formaldehyde emission and preparation method thereof

A technology of low formaldehyde release and composite material, applied in the field of low formaldehyde release polyoxymethylene composite material and its preparation, can solve the problems of poor thermal stability, limit the use range of materials, affect molding appearance, color and performance, etc. Stability, effect of reducing odor levels and formaldehyde emissions, good color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of polyoxymethylene composite material in the embodiment of the application is as follows:

[0035] Mix POM resin, primary antioxidant, secondary antioxidant, diisooctyl sebacate, allantoin, EBS and additives in a high-speed mixer for 1-2 minutes to obtain a premix, which is double- A screw extruder melts and extrudes at 150-220° C., cools, and pelletizes to obtain a polyoxymethylene composite material. Wherein, the temperature of each screw barrel of the twin-screw extruder from the feeding port to the machine head is respectively: 150°C-180°C, 170°C-220°C, 170°C-220°C, 170°C-210°C, 170°C- 210°C, 170°C-200°C, 170°C-200°C, 170°C-200°C, 170°C-200°C, 170°C-210°C, the screw speed is 250-350 rpm, and the feeding amount is 50-200kg / h, the degree of vacuum is (-0.1) ~ 0MPa.

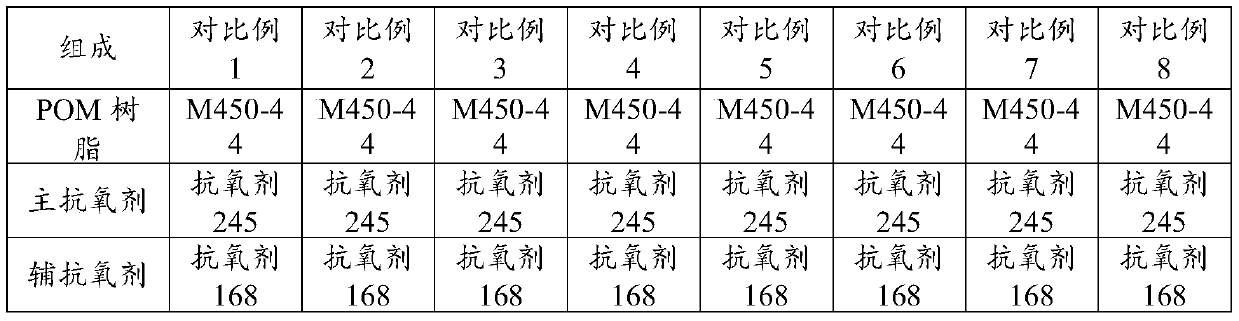

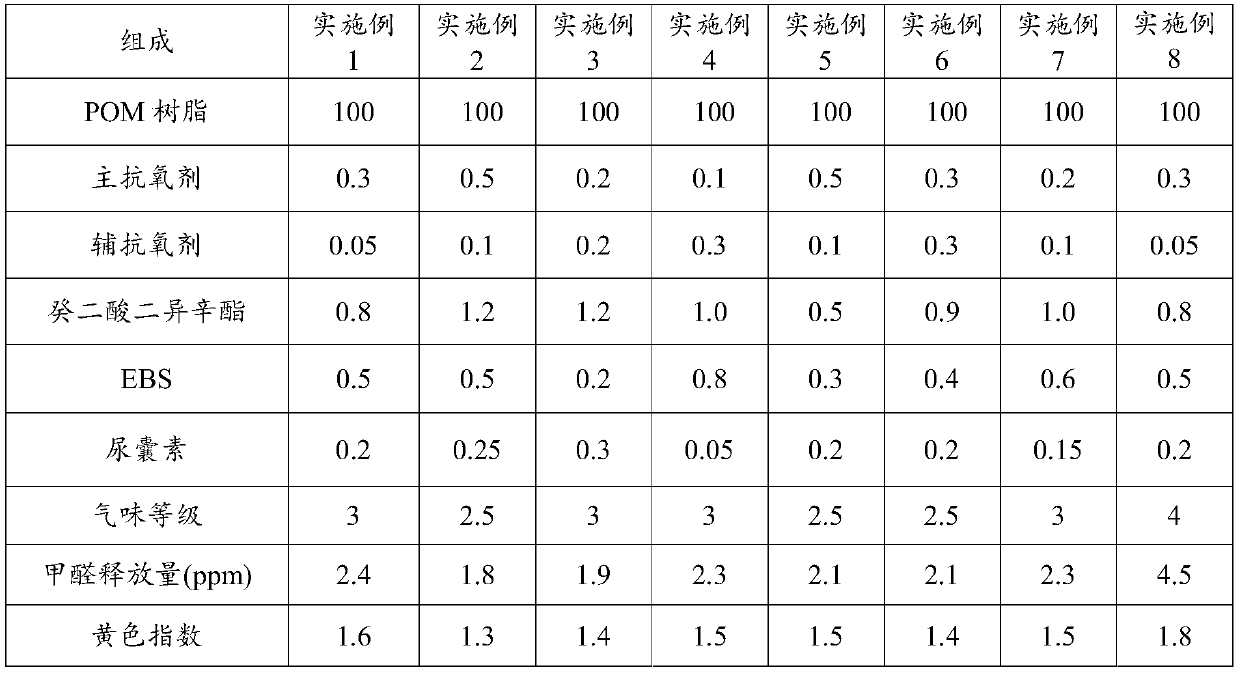

[0036] This application sets embodiment 1~8 and comparative example 1~8, and the specific selection of POM resin, antioxidant in embodiment 1~8 is as shown in table 1, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com