Castor-oil plant base environment-friendly cutting fluid composition

An environmentally friendly, castor-based technology, used in lubricating compositions, petroleum industry, etc., can solve problems such as restrictions, and achieve the effects of low odor, not easy to stink, and easy to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

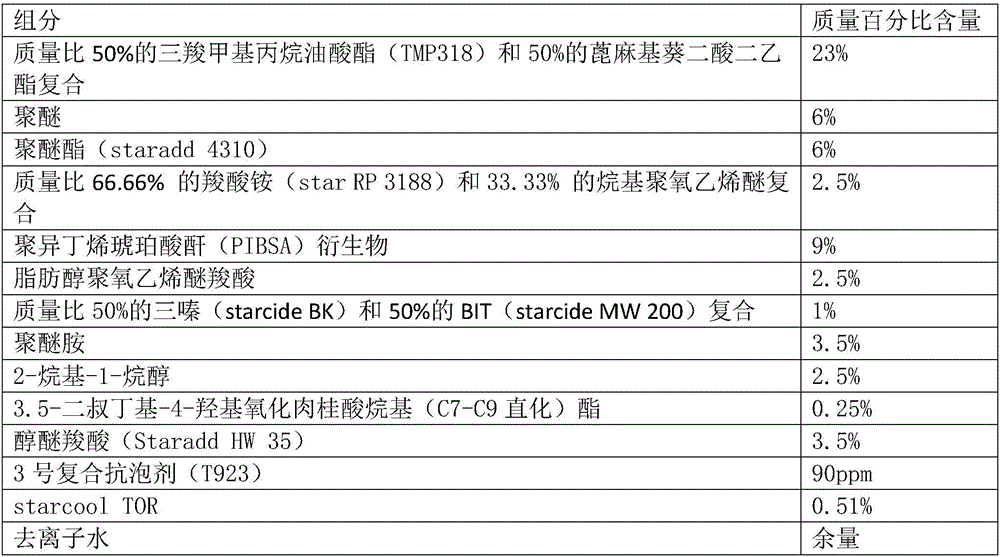

Embodiment 1

[0021] The following components are blended according to mass percentage:

[0022]

[0023] The sum of the mass percentages of the above components is 100%.

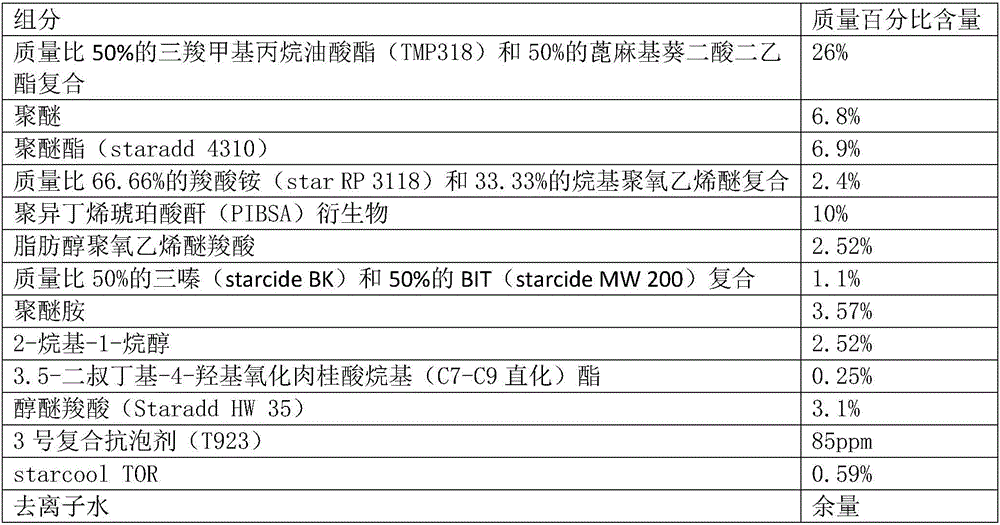

Embodiment 2

[0025] Blend the following mass percentages:

[0026]

[0027] The sum of the mass percentages of the above components is 100%.

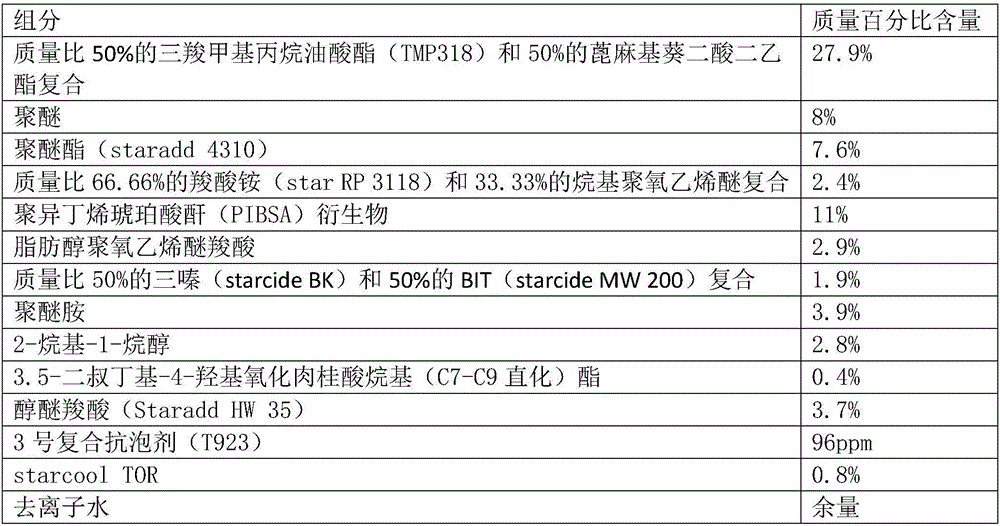

Embodiment 3

[0029] Blend the following mass percentages:

[0030]

[0031] The sum of the mass percentages of the above components is 100%.

[0032] The main technical index of embodiment 3 products

[0033]

[0034] The main technical index of embodiment 2 products

[0035]

[0036] The main technical index of embodiment 1 product

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com