Boric acid glycerin polyester-doped aluminum eletrolytic capacitor electrolyte and preparation method thereof

A technology of aluminum electrolytic capacitors and boric acid glycerol, which is applied in the direction of liquid electrolytic capacitors, can solve the problems of reduced or even increased flash voltage, improved conductivity, and low conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

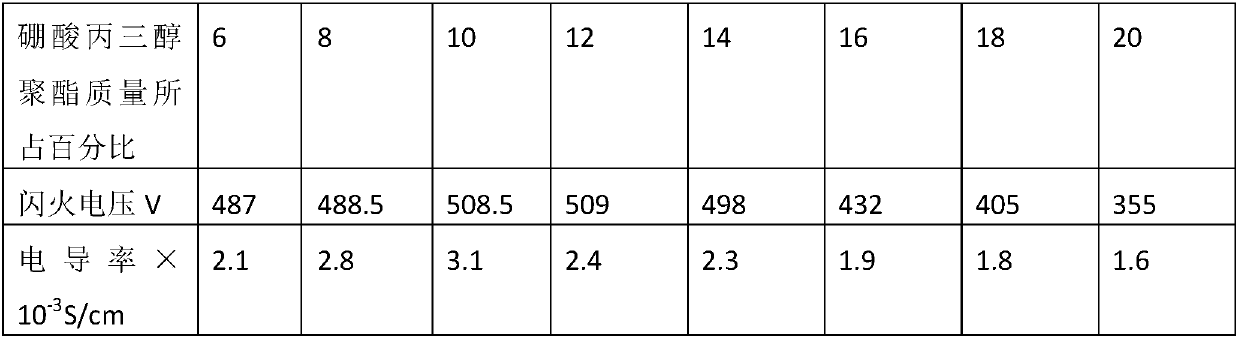

Image

Examples

Embodiment 1

[0012] Borate-doped glycerol polyester aluminum electrolytic capacitor electrolyte is configured according to the following raw material mass percentages: ammonium sebacate 4%; ethylene glycol 72.5%; diethylene glycol 17%; dioctyl sebacate 3%; boric acid Glycerol polyester 1%; water 3%; mannitol 0.5%; ammonium hydrogen azelate 0.5%; binder 1.2%; ammonium pentaborate 0.8%. The preparation method is to heat ethylene glycol, water, boric acid glycerol polyester to 60°C and keep it warm for 0.5h; raise the temperature to 60°C and add diethylene glycol and ammonium hydrogen azelate; raise the temperature to 130°C within 2min and keep it warm for 1h, Ammonium sebacate, mannitol, binder, ammonium pentaborate, and dioctyl sebacate were added; cooled to 100° C. and kept for 1 hour, then cooled in air to normal temperature to obtain the electrolyte.

[0013] The electrolytic solution of the boric acid-doped glycerol polyester aluminum electrolytic capacitor prepared according to the abo...

Embodiment 2

[0015] Borate-doped glycerol polyester aluminum electrolytic capacitor electrolyte is configured according to the following raw material mass percentages: ammonium sebacate 5%; ethylene glycol 60.8%; diethylene glycol 20%; dioctyl sebacate 5%; boric acid Glycerol polyester 5%; water 2%; mannitol 0.3%; ammonium hydrogen azelate 0.4%; binder 1%; ammonium pentaborate 0.5%. The preparation method is to heat ethylene glycol, water and boric acid glycerol polyester to 60°C and keep it warm for 0.5h; raise the temperature to 70°C and add diethylene glycol and ammonium hydrogen azelate; raise the temperature to 130°C within 2min and keep it warm for 1h, Ammonium sebacate, mannitol, binder, ammonium pentaborate, and dioctyl sebacate were added; cooled to 104° C. and kept for 1 hour, then cooled to room temperature in air to obtain the electrolyte.

[0016] The electrolytic solution of the boric acid-doped glycerol polyester aluminum electrolytic capacitor prepared according to the abov...

Embodiment 3

[0018] Borate-doped glycerol polyester aluminum electrolytic capacitor electrolyte is configured according to the following raw material mass percentages: ammonium sebacate 6%; ethylene glycol 55%; diethylene glycol 24%; dioctyl sebacate 3%; boric acid Glycerol polyester 6%; water 3%; mannitol 0.5%; ammonium hydrogen azelate 0.5%; binder 1.2%; ammonium pentaborate 0.8%. The preparation method is to heat ethylene glycol, water, boric acid glycerol polyester to 60°C and keep it warm for 0.5h; raise the temperature to 65°C and add diethylene glycol and ammonium hydrogen azelate; raise the temperature to 130°C within 3min and keep it warm for 1h, Ammonium sebacate, mannitol, binder, ammonium pentaborate, and dioctyl sebacate were added; cooled to 95° C. and kept for 1 hour, then cooled to room temperature in air to obtain the electrolyte.

[0019] The electrolytic solution of the boric acid-doped glycerol polyester aluminum electrolytic capacitor prepared according to the above te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com