Electrostatic DOS (dioctyl sebacate) oil spraying method

An electrostatic and positive charge technology, applied in the field of strip production, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

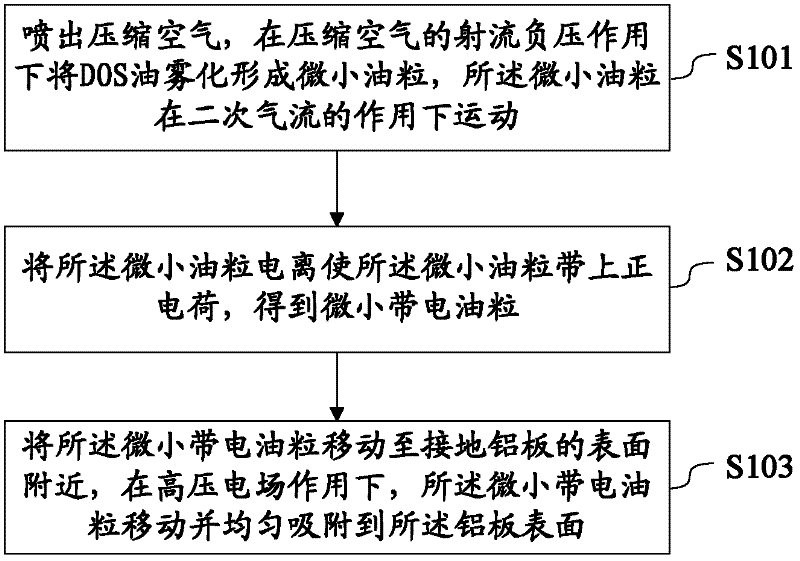

Method used

Image

Examples

Embodiment 1

[0046] Corresponding to the method provided in Embodiment 1 of a method of electrostatically applying DOS oil in the above-mentioned application, see Figure 5 , the application also provides a device embodiment 1 of electrostatically coating DOS oil, in this embodiment, the device may include:

[0047] Atomizer 101, secondary airflow controller 102, ionizer 103 and coater 104;

[0048] in:

[0049] The atomizer 101 is used to spray compressed air, and atomize the DOS oil to form tiny oil particles under the jet negative pressure of the compressed air;

[0050] The secondary airflow controller 102 is used to issue and control the secondary airflow to blow the moving position of the tiny oil particles;

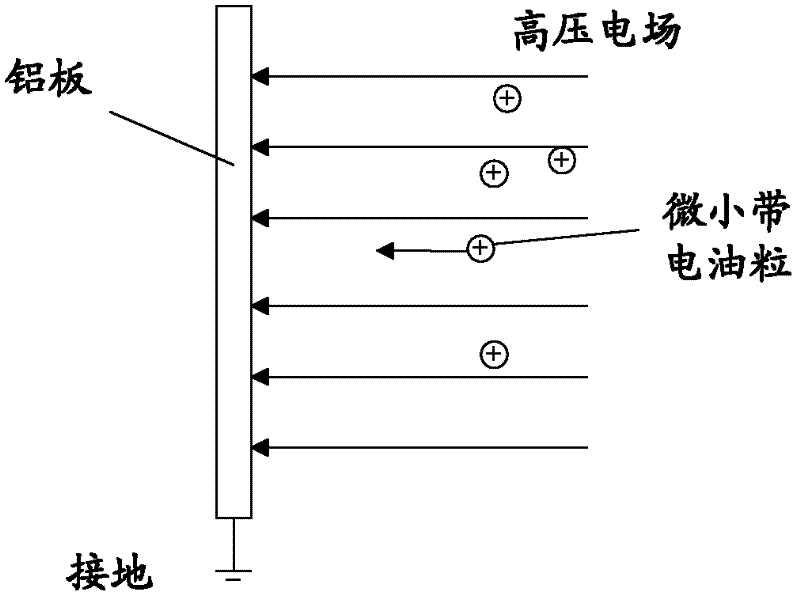

[0051] The ionizer 103 is used to ionize the tiny oil particles so that the tiny oil particles are positively charged to obtain tiny charged oil particles;

[0052] The coater 104 is used to generate a high-voltage electric field, so that the tiny charged oil particles move...

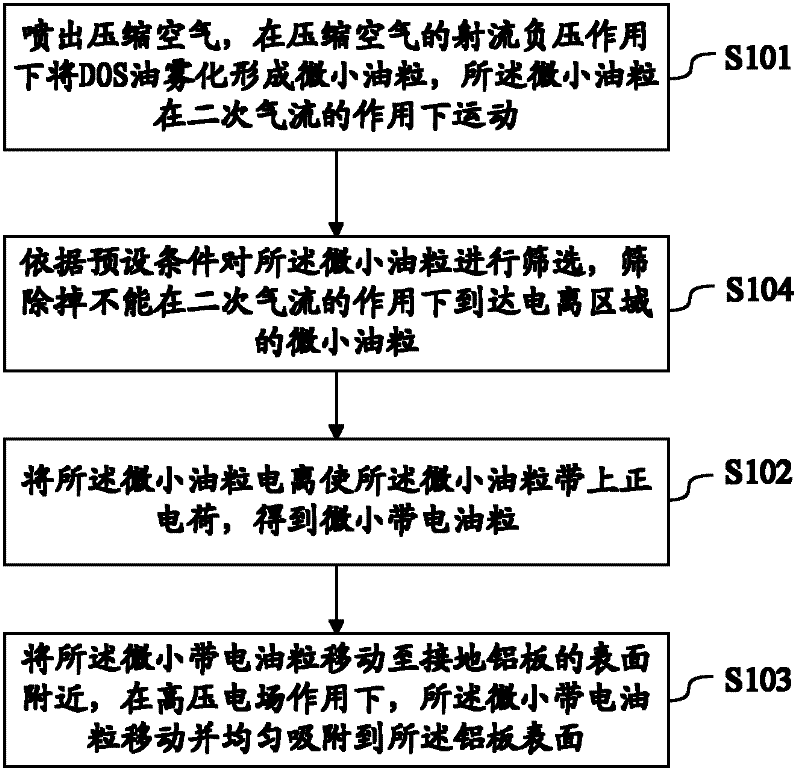

Embodiment 2

[0054] Corresponding to the method provided in Embodiment 2 of a method of electrostatically coating DOS oil in the above-mentioned application, see Figure 6 , the present application also provides a device embodiment 2 of electrostatically applying DOS oil. In this embodiment, the secondary airflow controller 102 may also include:

[0055] The regulator 1021 is used to adjust the gas velocity of the secondary airflow.

[0056] In order to obtain uniform tiny oil particles and save DOS oil, it is necessary to screen the tiny oil particles. One of the screening conditions is to filter the size of the tiny oil particles by setting the speed of the secondary airflow.

[0057] The tiny oil particles move under the blowing of the secondary airflow, among which the larger oil particles have a greater gravity, and the speed in the direction of the secondary airflow is small, and the moving distance cannot reach the ionization area, so they are screened out and flow back to the fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com