Method for detecting dibutyl sebacate and acetyl tributyl citrate in film material

A technology of acetyl tributyl citrate and dibutyl sebacate, which is applied in the field of detection of dibutyl sebacate and acetyl tributyl citrate in membrane materials, can solve the problems of few reports and literature, Achieve the effect of simple operation, high economic and social value, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1.1 Reagents, standards and materials

[0040] Methanol, n-hexane, dichloromethane: chromatographically pure, Merck; dibutyl sebacate, chemical substance registration number (CAS): 109-43-3, purity 99.4%, Shanghai Anpu Experiment Technology Co., Ltd. Acetyl tributyl citrate: CAS: 77-90-7, purity 98%, Shanghai Anpu Experimental Technology Co., Ltd.; organic filter membrane: pore size 0.45 μm, Tianjin Keyilong Experimental Equipment Co., Ltd. PVDC film was used as the test sample.

[0041] 1.2 Sample preparation

[0042] Select 3 PVDC film samples and 3 PVDC composite film samples as test samples, and detect and analyze the dibutyl sebacate and acetyl tributyl citrate contained in the samples. The sample number is 1 # ,2 # 、3 # 、4 # 、5 # 、6 # .

[0043] Weigh 5.0g of sample, cut or pulverize the sample into individual fragments, the particle size should be ≤0.2cm, mix evenly; do blank test at the same time.

[0044] Accurately weigh 0.20g (accurate to 0.1mg) of t...

Embodiment 2

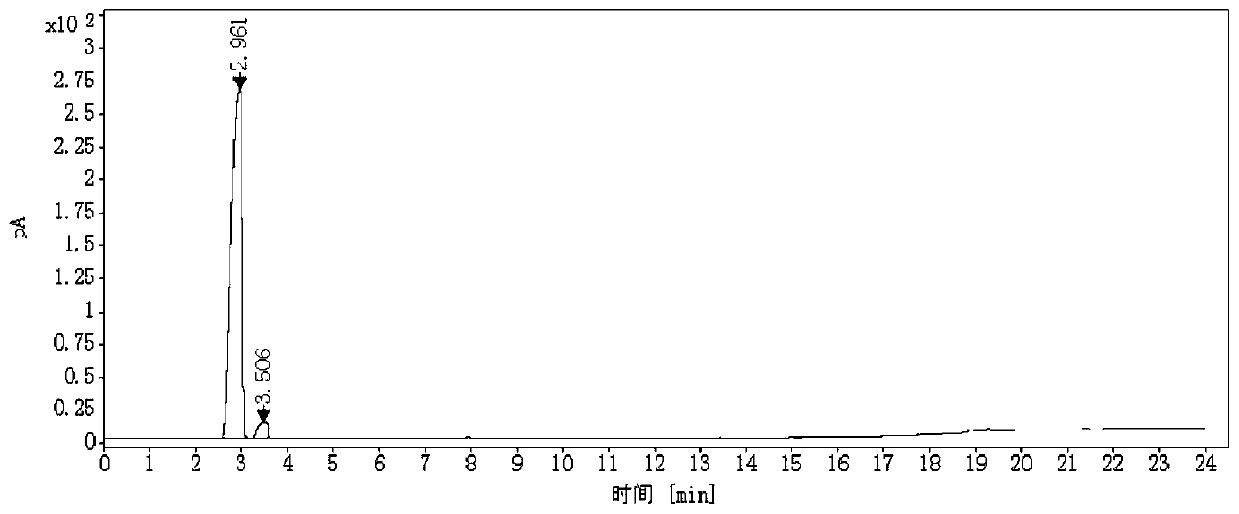

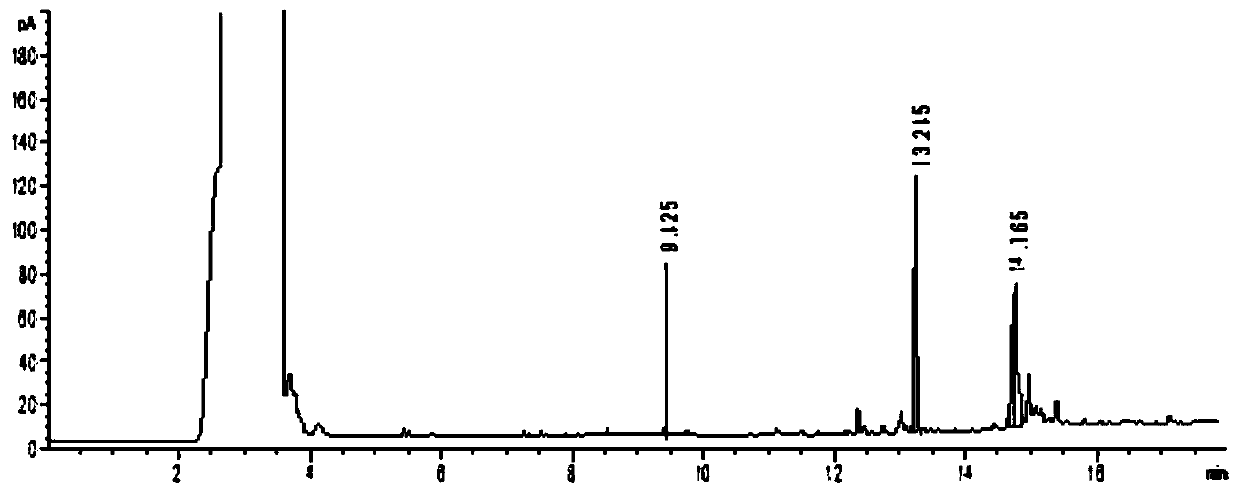

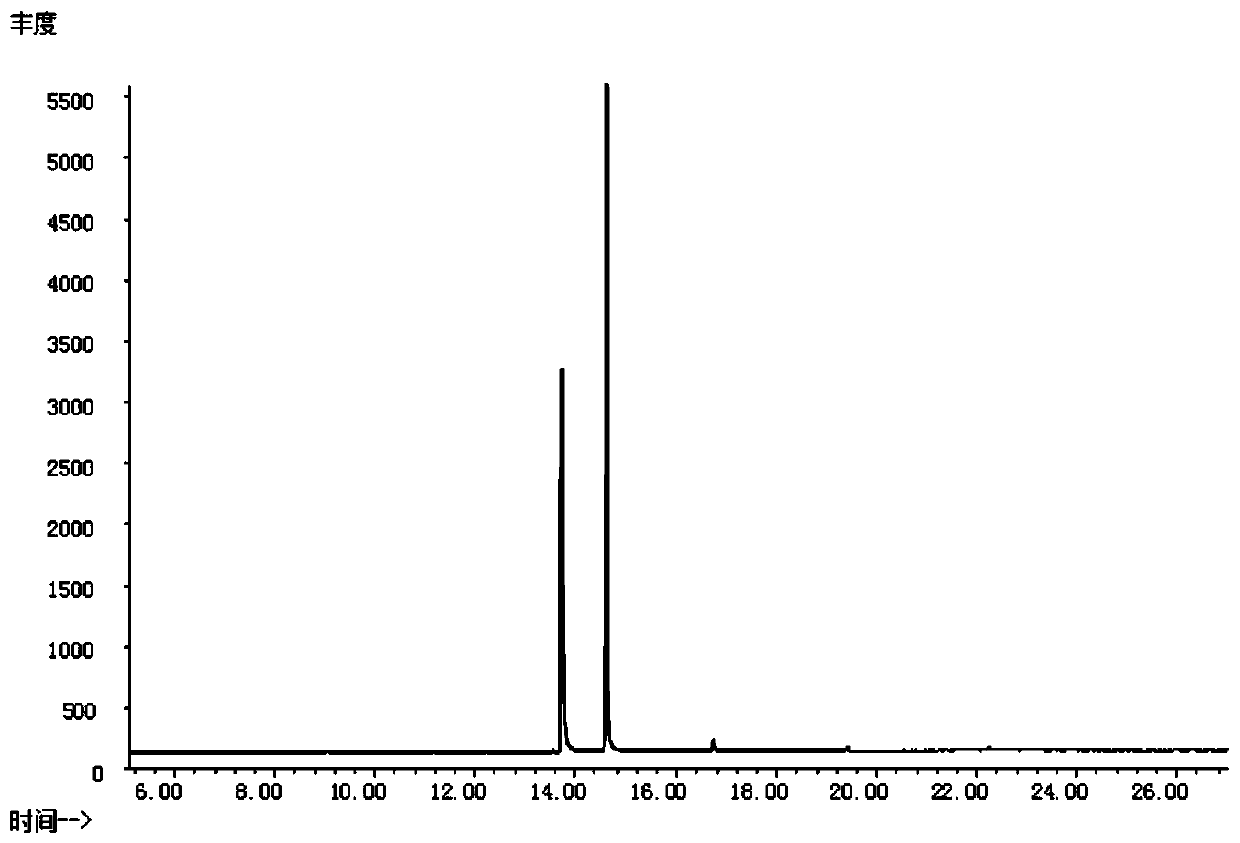

[0049] 2.1 Selection of chromatographic column

[0050] Capillary column: TR-FFAP type chromatographic column (30m×0.32mm×0.25μm) strong polar chromatographic column, the polar stationary phase is polyethylene glycol, the response value of the two target substances is too low during separation, and the separation effect is not good. In addition, the boiling points of dibutyl sebacate and acetyl tributyl citrate are 178°C and 343°C respectively, and the maximum tolerance temperature of the TR-FFAP column is 250°C. not good, such as figure 1 shown. The DB-1 type capillary column (30m×0.25mm×0.50μm) has a poor separation effect on acetyl tributyl citrate, such as figure 2 shown. DB-5MS type capillary column (30m×0.25mm×0.25μm) has good separation effect and good peak shape. Since the maximum temperature tolerance is 350°C, the column loss is very low, and it is inert to active compounds. It has higher sensitivity and mass spectrometry Figure integrity, is an ideal non-polar ...

Embodiment 3

[0068] a. Chromatographic conditions

[0069] Chromatographic column: DB-5MS quartz capillary column (30m×0.25mm×0.25μm); heating program: initial column temperature is 60°C, keep it for 1min, raise the temperature to 220°C at 20°C / min, keep it for 1min, then increase the temperature at 5°C / min The temperature was raised to 280°C and kept for 5 minutes, the flow rate of carrier gas (He) was 1mL / min, the sampling method was splitless injection, and the injection volume was 1.0 μL. Injection port temperature: 280°C.

[0070] b. Mass Spectrometry Conditions

[0071] Electron impact (EI) ion source; electron energy: 70eV; ion source temperature: 230°C; transfer line temperature: 280°C; quadrupole temperature: 150°C; solvent delay time: 5min; monitoring method: selected ion scanning mode (SIM) . See Table 5 for the quantitative and qualitative ions of dibutyl sebacate and acetyl tributyl citrate.

[0072] Table 5 Fragment ion information of dibutyl sebacate and acetyl tributyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com