Dental implant carrying device and implantation tool assembly

A technology for dental implants and tools, which is applied in the fields of dental implants, dentistry, and dental repairs, etc. It can solve the problems of high processing costs, reduced convenience, and increased operation time, and achieves high production efficiency, both elasticity and hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

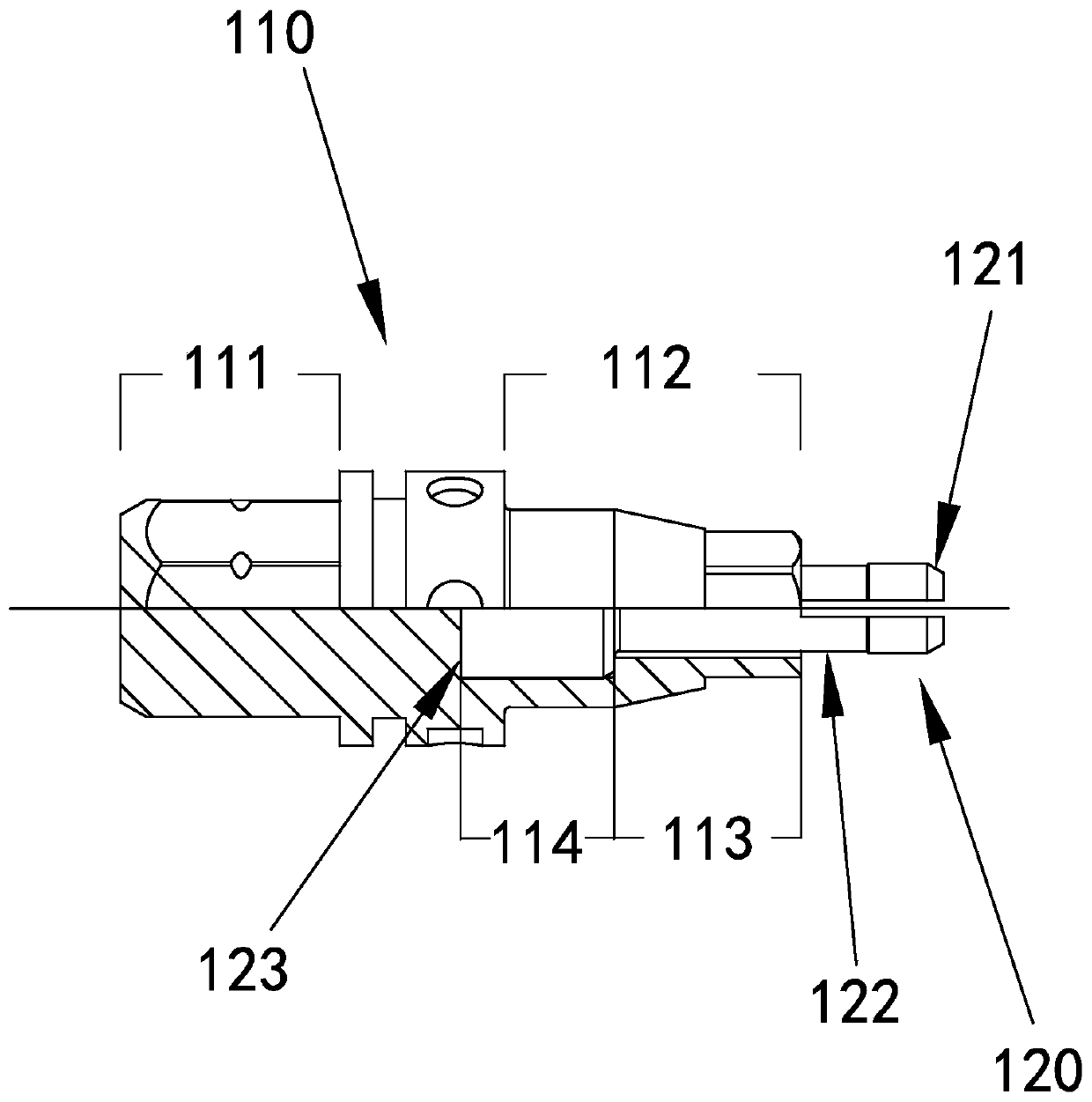

[0032] Embodiment 1, a kind of dental implant carrying device, such as figure 1 shown, including:

[0033] The carrying body 110 is a columnar member, one end of which is provided with an implant tool coupling section 111 , and the other end is provided with a dental implant coupling section 112 . The implant tool combining section 111 is adapted to the implant tool interface of the peripheral device. The dental implant coupling section 112 is adapted to the abutment interface of the peripheral dental implant. The carrier 110 is provided with a connector installation hole, the connector installation hole extends from the end face of the dental implant joint section 112 to the carrier 110 along the axis of the carrier 110, and the connector installation hole sequentially includes the first A hole segment 113 and a second hole segment 114 , the diameter of the first hole segment 113 is smaller than the second hole segment 114 , and the first hole segment 113 is close to the en...

Embodiment 2

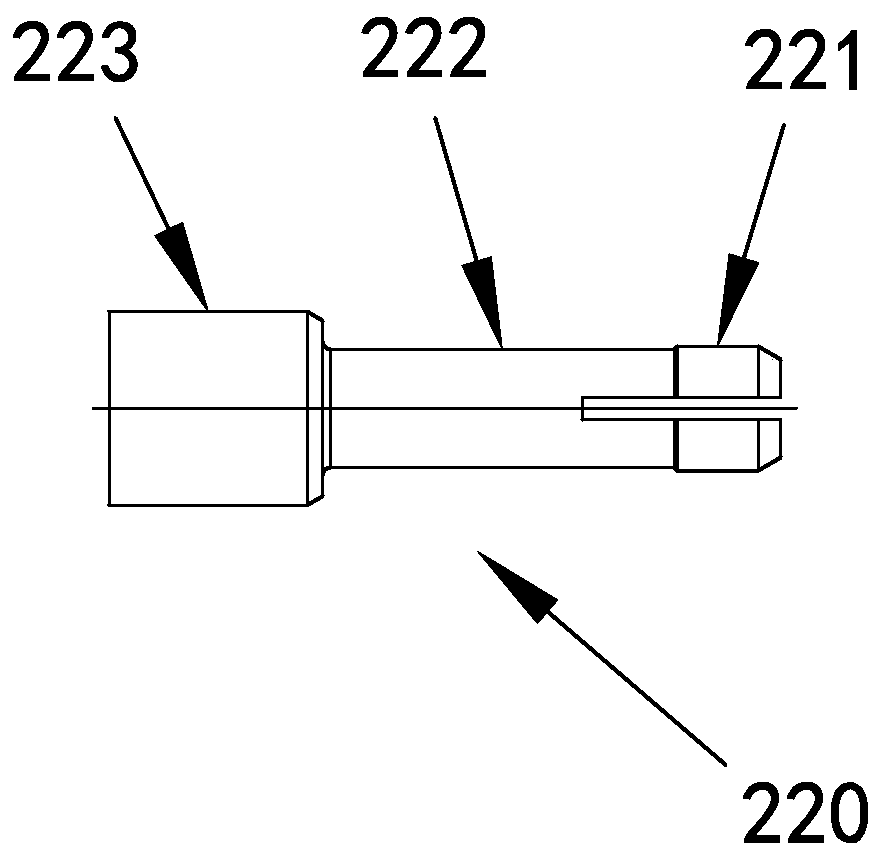

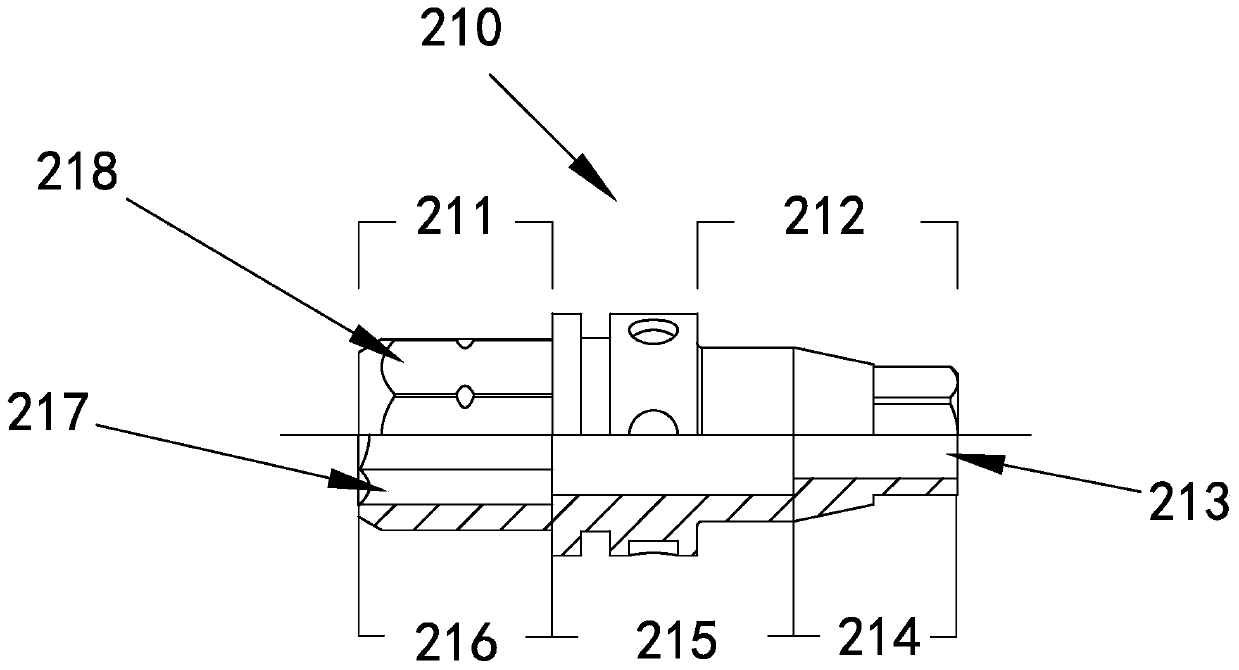

[0036] Embodiment 2, a kind of dental implant carrying device, such as figure 2 and 3 shown, including:

[0037] like image 3 As shown, the carrier 210 is a columnar member, one end of which is provided with an implant tool coupling section 211 , and the other end is provided with a dental implant coupling section 212 . The implant tool coupling section 211 is adapted to the external implant tool interface; the dental implant coupling section 212 is adapted to the abutment interface of the external dental implant. The carrier 210 is provided with a connector installation hole 213, the connector installation hole 213 runs through the carrier 210 along the axis of the carrier 210, and the connector installation hole 213 sequentially includes a first hole section 214, a second Two hole segments 215 and a third hole segment 216, the diameter of the first hole segment 214 is smaller than the second hole segment 215, the first hole segment 214 is close to the end surface of the...

Embodiment 3

[0040] Embodiment 3, a kind of internal implantation tool, such as Figure 4 As shown, it includes: a cylindrical first body 300 , and the first body 300 includes a first driving coupling portion 301 and a first implant tool interface 302 . The first driving coupling part 301 is compatible with the connection port of the external torque wrench, and the first implant tool interface 302 is compatible with the second hole section 215 and the third hole section 215 of the dental implant carrying device described in Embodiment 2. The hole segment 216 is adapted, especially the contour of the surface of the first implant tool interface 302 fits with the inner hexagonal anti-rotation structure in the third hole segment 216 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com