Automotive suspension test bed

A technology of automobile suspension and test bench, which is applied in the direction of vehicle suspension/shock absorption mechanism testing, etc., can solve the problems of heavy body fixing fixture, difficult adjustment, and increased test cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

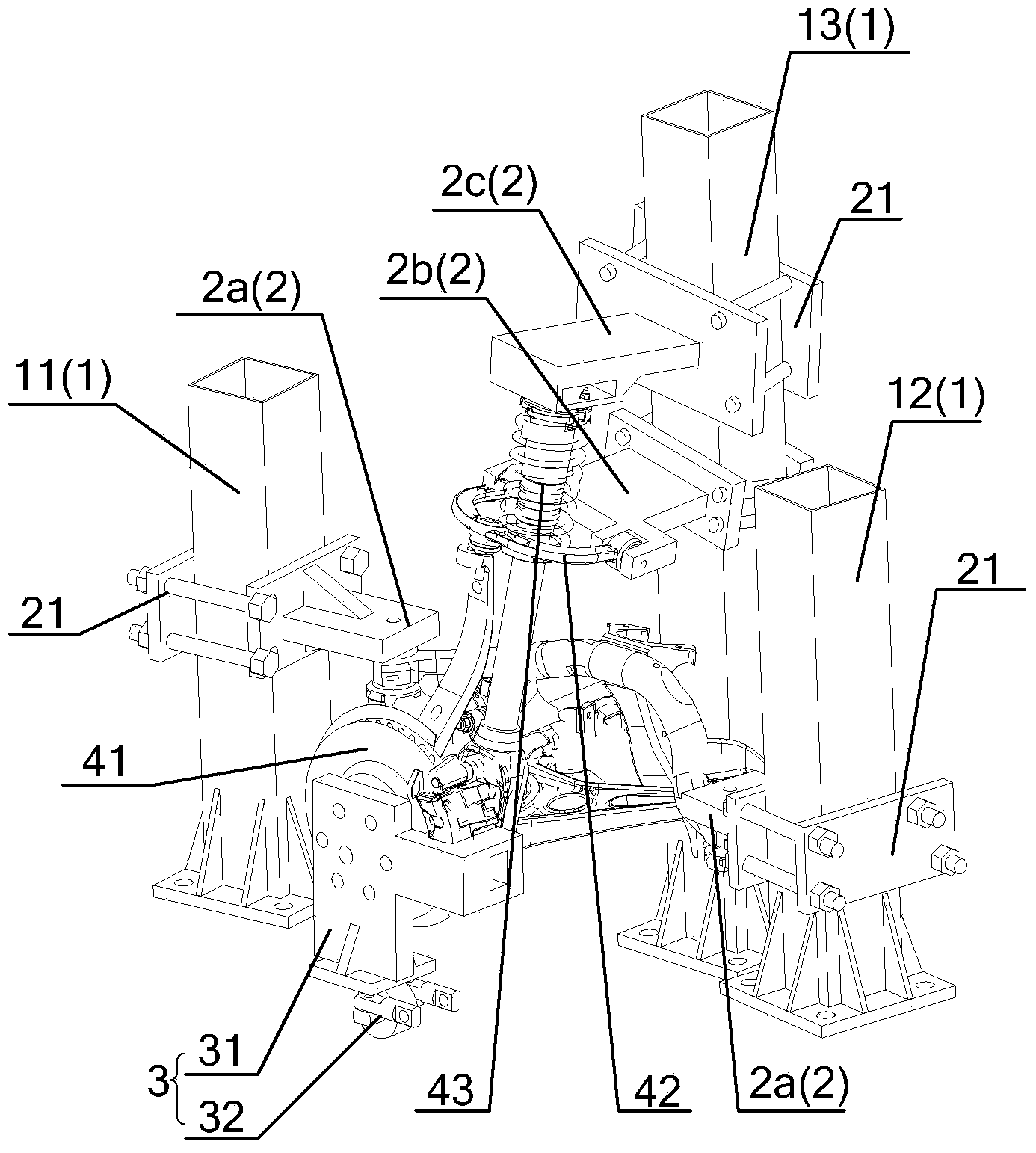

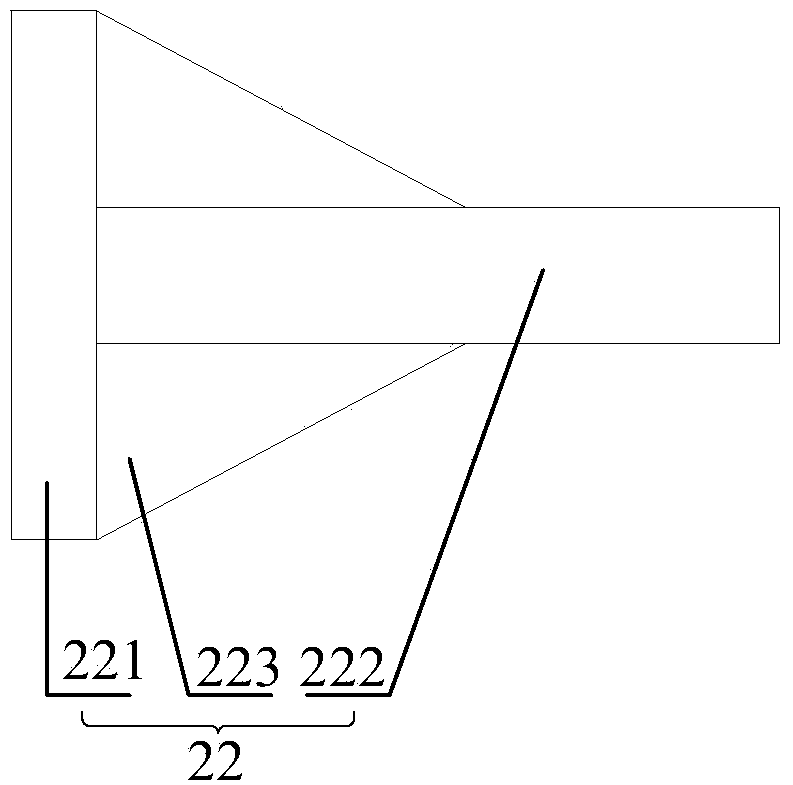

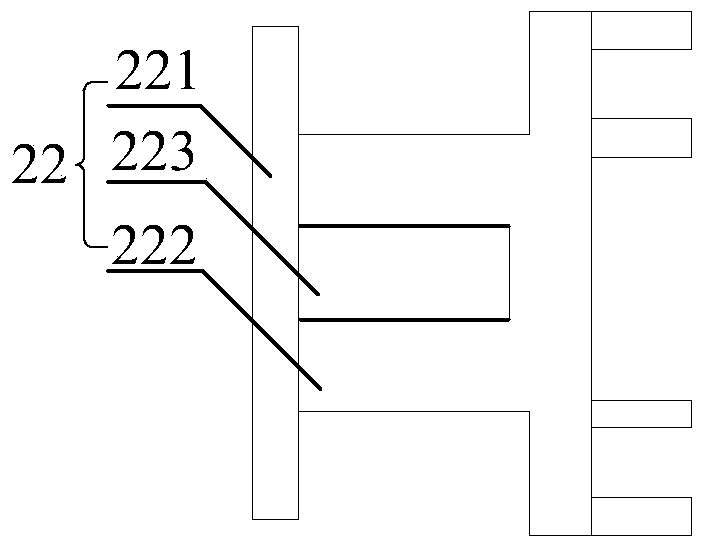

[0026] An automobile suspension test bench according to an embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] The embodiment of the present invention provides a kind of automobile suspension test bench, such as figure 1 As shown, it includes a plurality of columns 1, and the height and angle adjustable splint 2 are installed on the column 1; calibration symbols are also provided on the column 1, which are used to mark the installation position of the splint 2; the automobile suspension test bench also includes Connect the loading mechanism 3 of the loading device (not shown in the figure); the column 1 is matched and connected with the automobile frame through the splint 2 and assembled, the loading mechanism 3 is connected with the brake disc 41 on the vehicle frame, and the direction of the loading device is controlled to make the loading mechanism 3 in Suspension durability verification under differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com