Method for determining assembly interference magnitude and heat preservation point of motor stator

A technology of motor stator and interference, which is applied in the field of automobile assembly, can solve the problems of small load torque, deviation of calculation result guidance, cost and time consumption, etc., achieve clear value results and avoid the effect of positioning dimension out-of-tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Referring to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention include the shape, structure, mutual position and connection relationship of each part, the function and working principle of each part, and the manufacturing process of the various components involved. And the method of operation and use, etc., are described in further detail to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

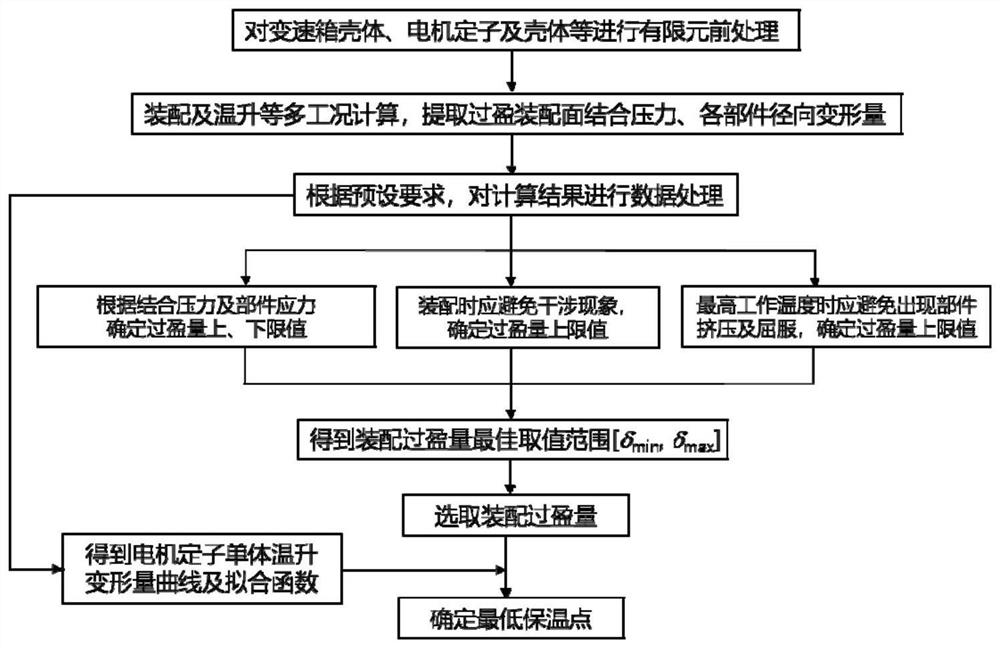

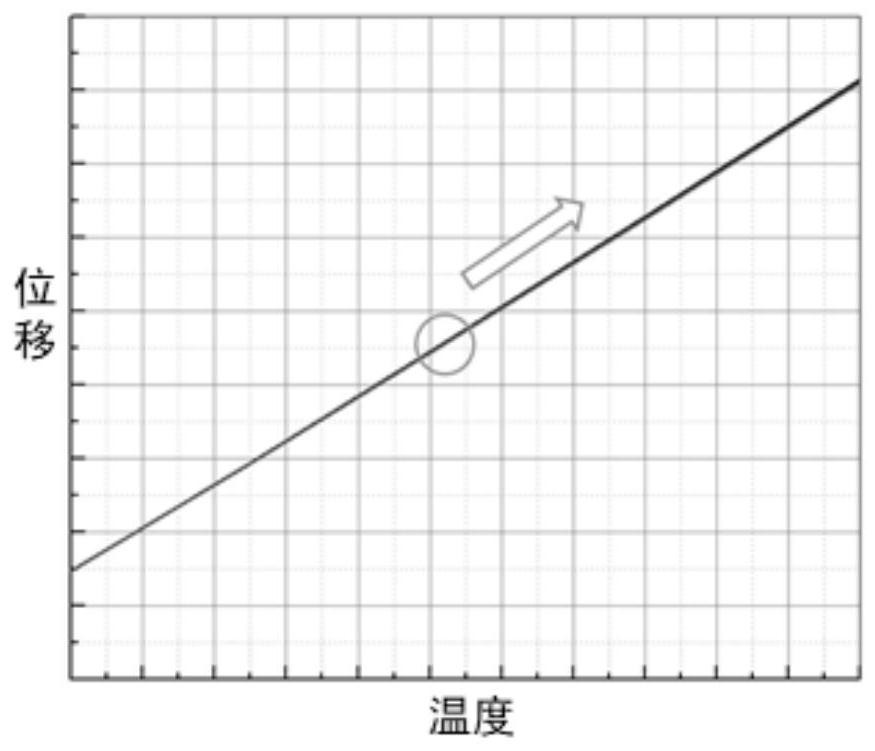

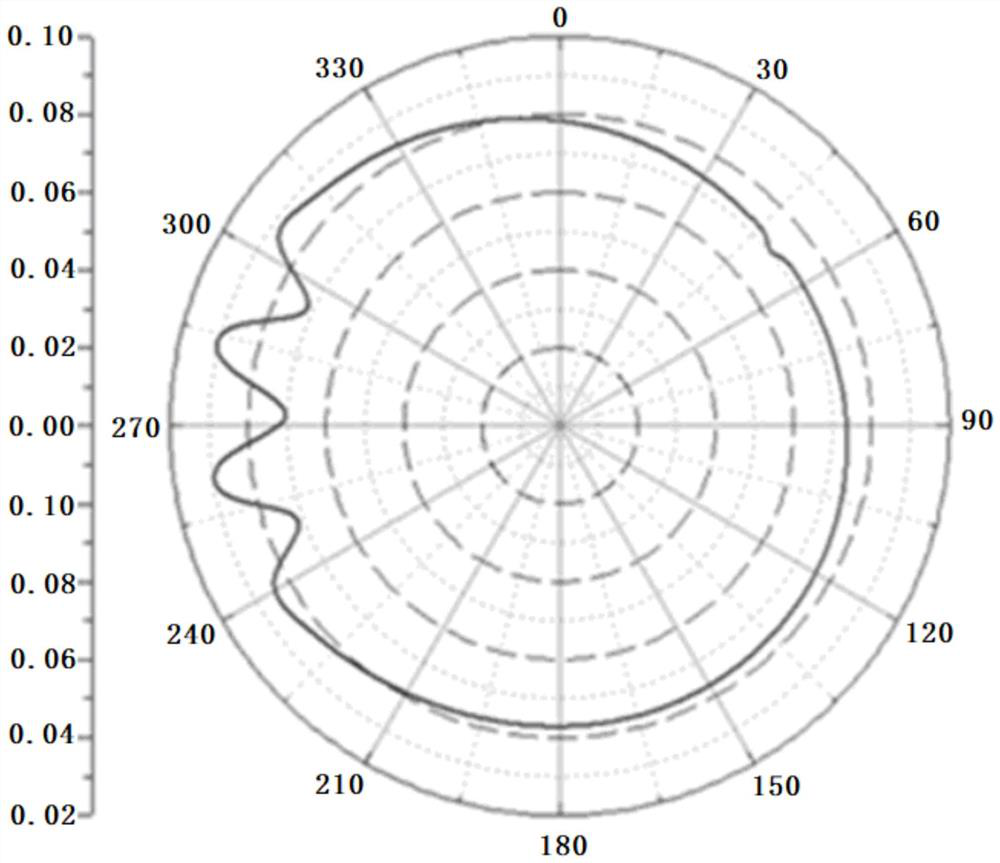

[0022] This method takes into account the influence of the component's detailed structural stiffness, contact nonlinearity, and material parameters' dynamic changes with temperature on the deformation. By analyzing the assembly conditions and temperature rise conditions of the motor stator, motor housing and gearbox housing in the finite element simulation software, and analyzing and processing the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com