Multi-structure layer design method for high-speed milling tool

A design method and high-speed milling technology, applied in milling cutters, milling machine equipment, metal processing equipment, etc., can solve the problems of design conflicts, too many design loops, service performance decline of high-speed milling cutters, etc., to reduce the degree of design coupling, solve the The effect of service performance degradation, high safety and high cutting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

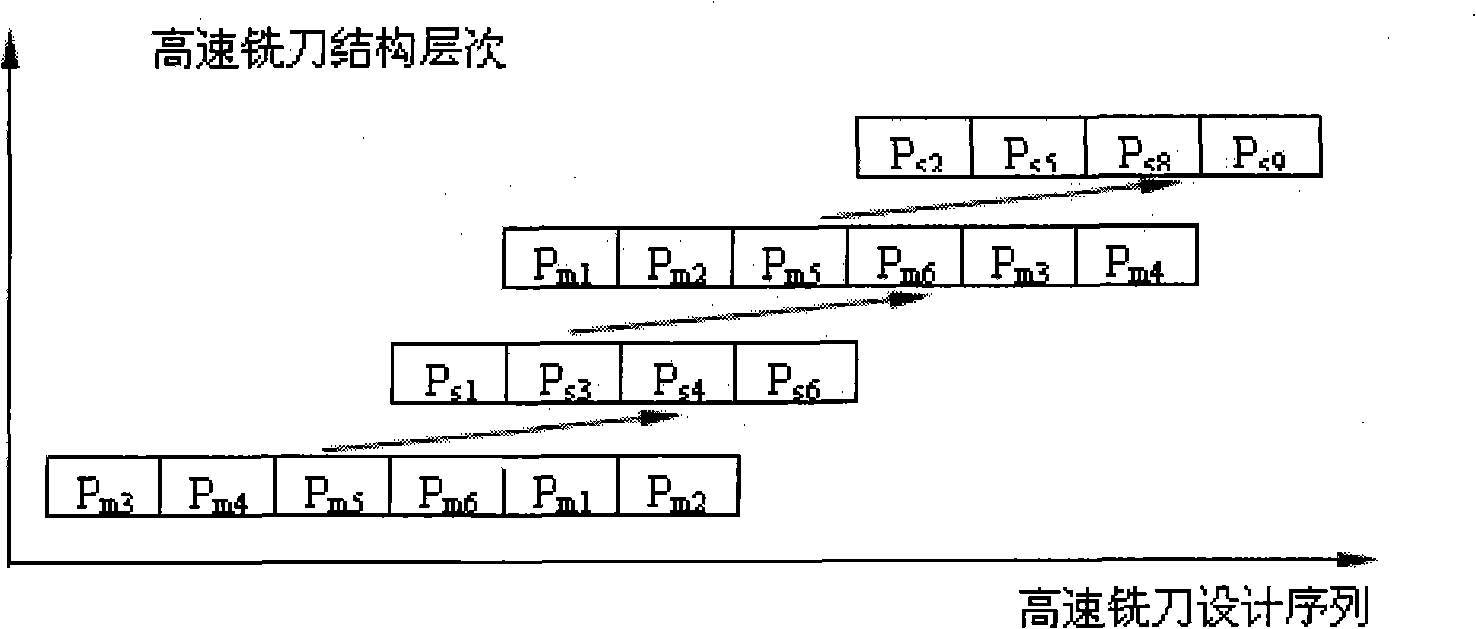

[0023] A multi-level design method for high-speed milling cutters, the method includes the following steps:

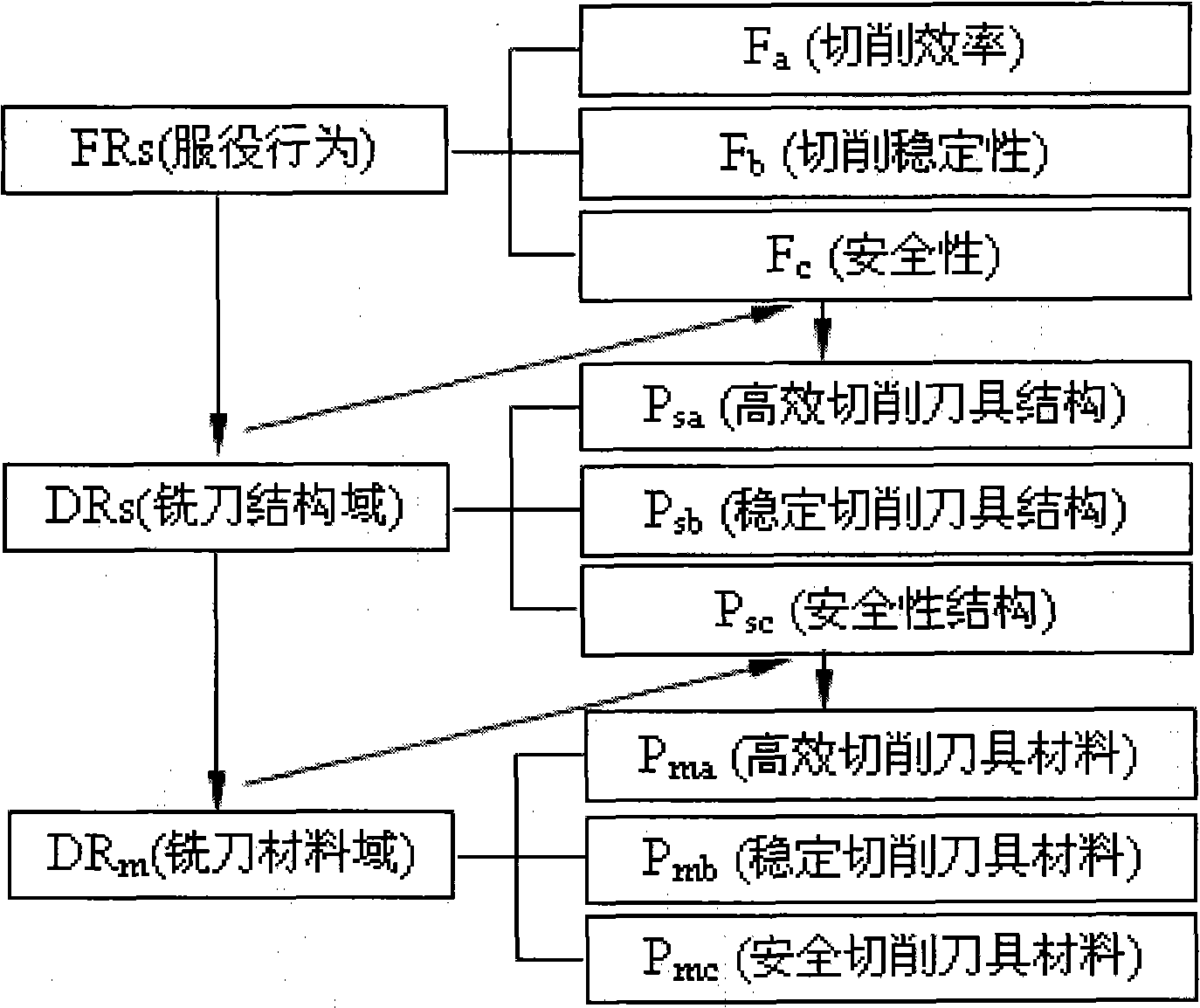

[0024] (1) Using the existing high-speed milling cutter vibration reduction model, combined with the analysis of the service characteristics of the milling cutter, the data related to the impact of the structure, material and cutting parameters of the milling cutter on the service performance of the milling cutter during the high-speed milling process are obtained, and the service behavior of the high-speed milling cutter is constructed. Structural Hierarchy Model;

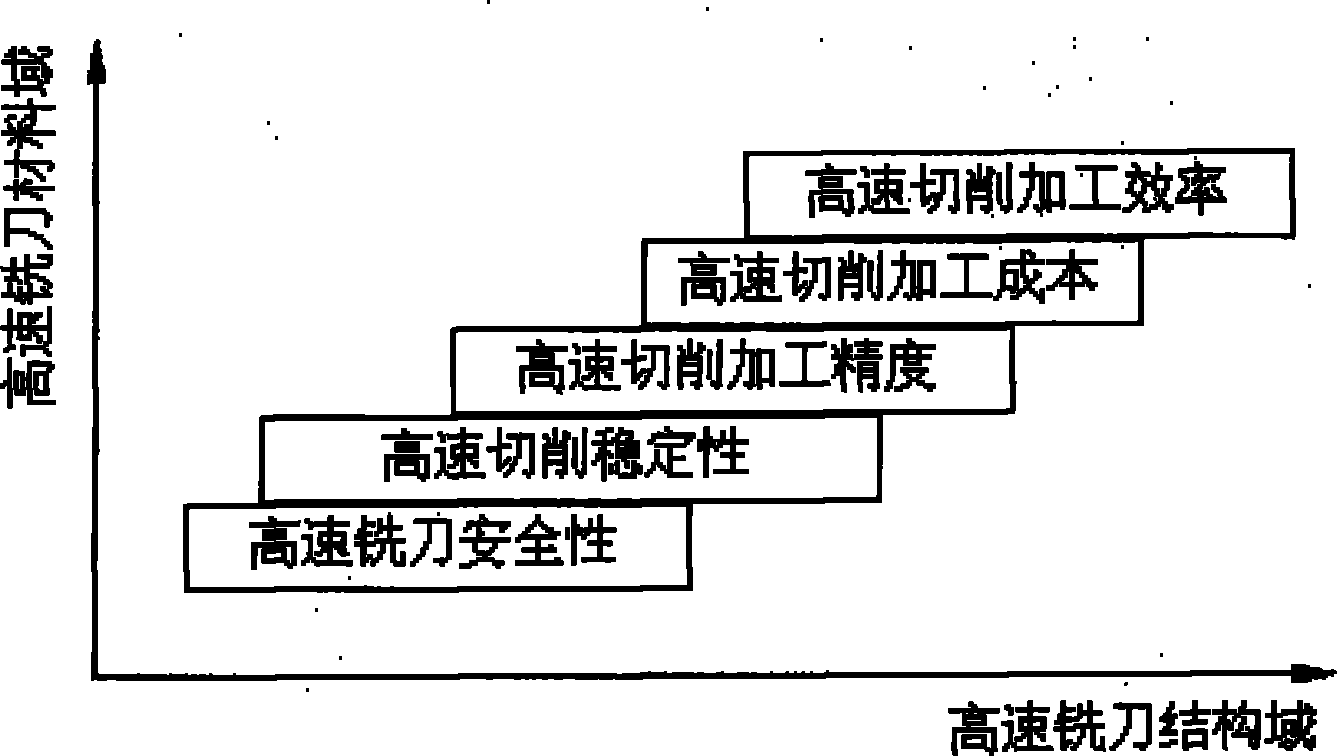

[0025] According to the demand hierarchy theory, good service behavior is not only a high-level functional requirement for high-speed milling cutters, but also an important guarantee for high-speed cutting. Therefore, the service behavior of high-speed milling cutters not only comprehensively reflects the state and performance of milling cutters in the high-speed cutting process, but also can more comprehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com