Hydraulic connector integration system

An integrated system and hydraulic joint technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as shared data, process information cannot be automated, CAPP cannot directly obtain CAD feature information, etc., to reduce production costs, Satisfy the effect of product diversification and personalization and shorten the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

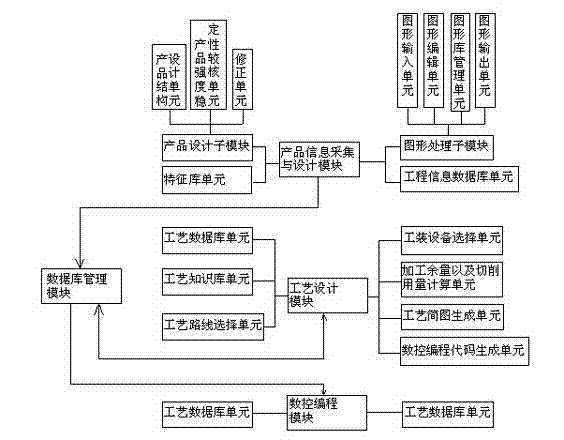

[0020] like figure 1 An integrated system of hydraulic joints is shown, including product information collection and graphic design modules, process design modules, numerical control programming modules and database management modules;

[0021] The product information collection and graphic design module collects the overall information and part information of the product to be designed for preliminary product design, and draws part diagrams and product assembly diagrams. The product information collection and graphic design module includes a product design sub-module, a feature library unit, a graphic processing sub-module and an engineering information database unit; the product design sub-module performs product design according to the required product collection information, and inputs the information into the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com