Top-level impeller on condensate extraction pump for nuclear power station

A first-stage impeller and condensate pump technology, which is applied to components, pumps, and pump components of pumping devices for elastic fluids, and can solve the problems of high weight and cost of pump sets, poor stability of pump sets, and high pressure in straight pipes, etc. problem, to achieve the effect of reducing the necessary NPSH, reducing hydraulic loss, and reducing the relative velocity of the inlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

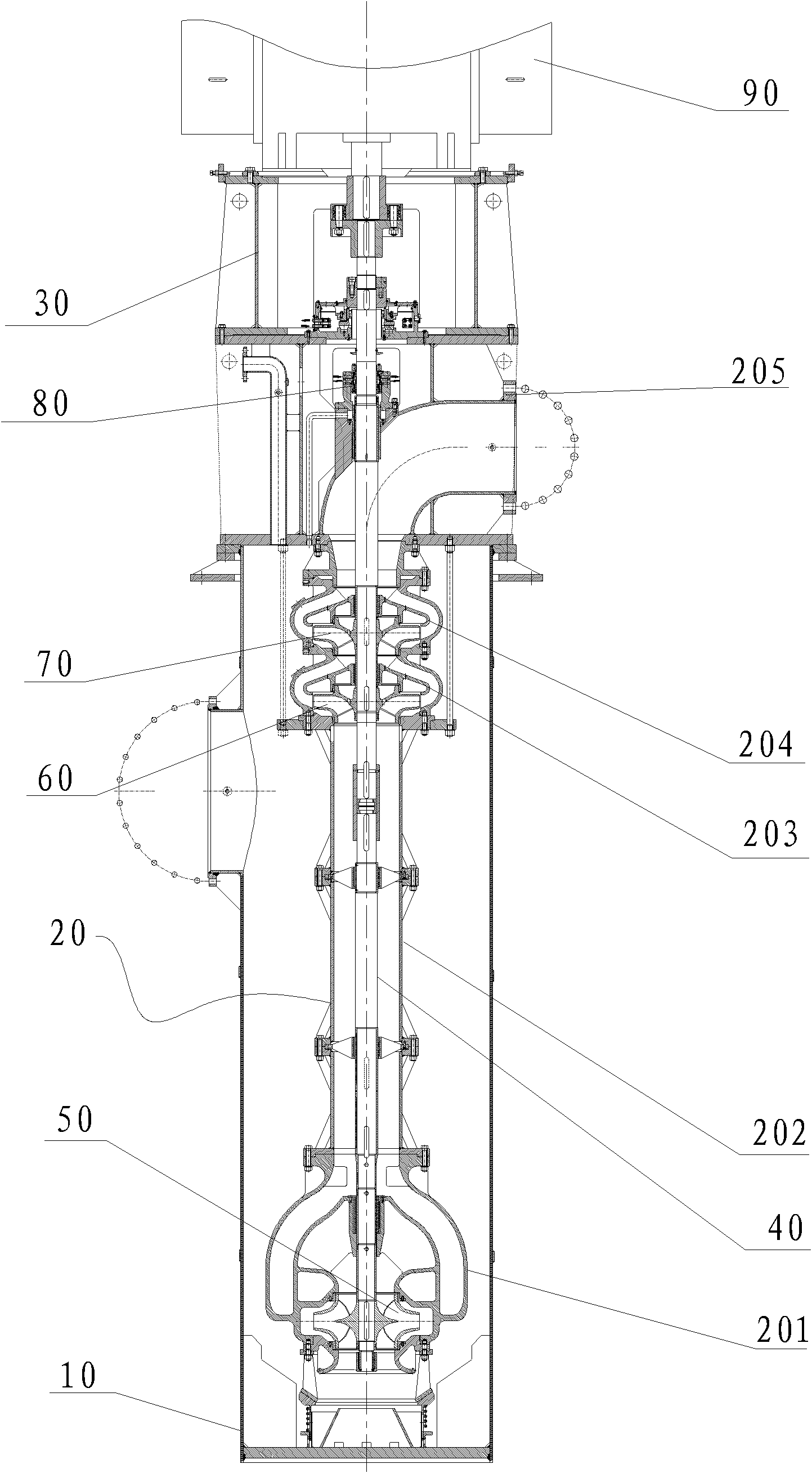

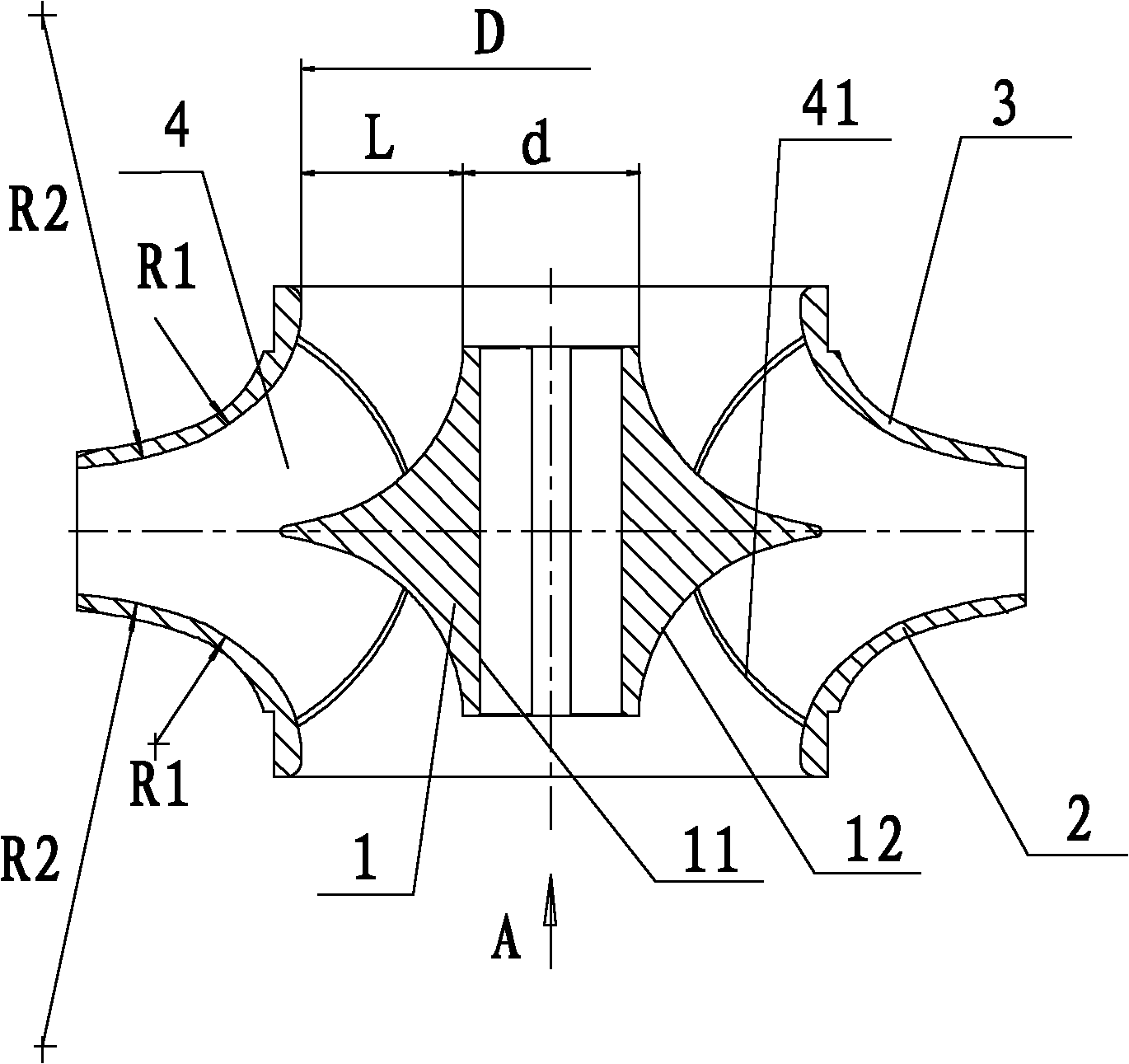

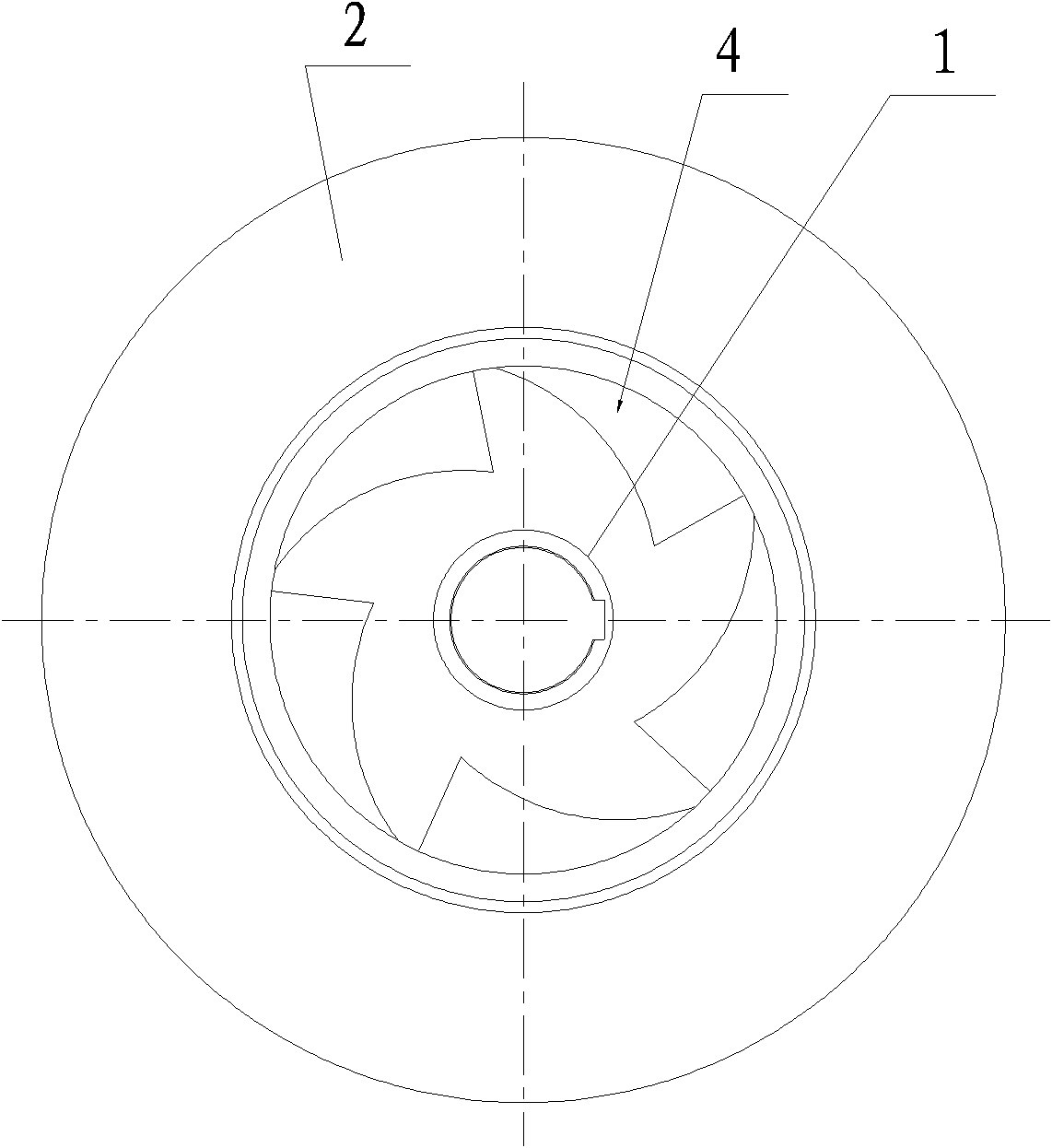

[0015] see figure 1 , The condensate pump includes a vertical outer cylinder 10 , pump body 20 , motor frame 30 , pump shaft 40 , first stage impeller 50 , secondary impeller 60 , last stage impeller 70 , mechanical seal 80 , bearing assembly and motor 90 . The pump body 20 includes a double-suction volute case 201, a straight pipe 202, a secondary guide vane 203, a final guide vane 204, a water outlet housing 205, a first-stage impeller 50, and a secondary impeller that are coaxially connected to each other in sequence from bottom to top. 60 and the last-stage impeller 70 are fixedly sleeved on the pump shaft 40 and are respectively arranged in the inner cavity of the double-suction volute case 201 , the secondary guide vane 202 and the final-stage guide vane 203 .

[0016] see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com