Rotor type immersible pump with eccentric shaft directly connected with motor

An eccentric shaft and submersible pump technology, which is applied in the field of positive displacement pumps, can solve the problems of low reciprocating times, poor casting process, and low cost, and achieve the effects of stable liquid flow output without pulse, reduced axial size, and small hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

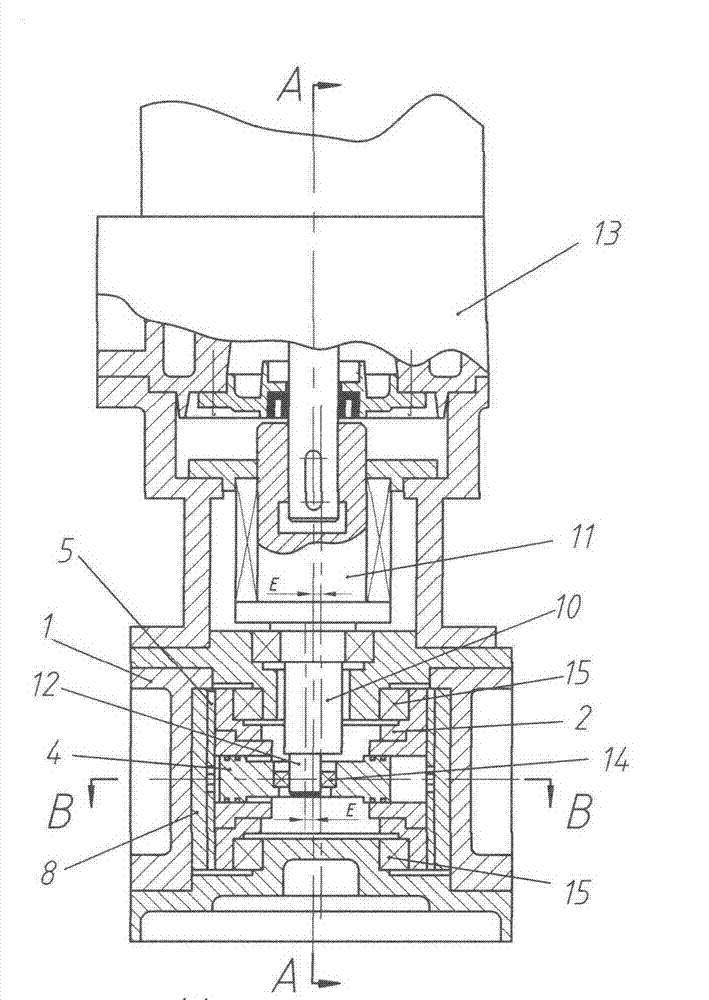

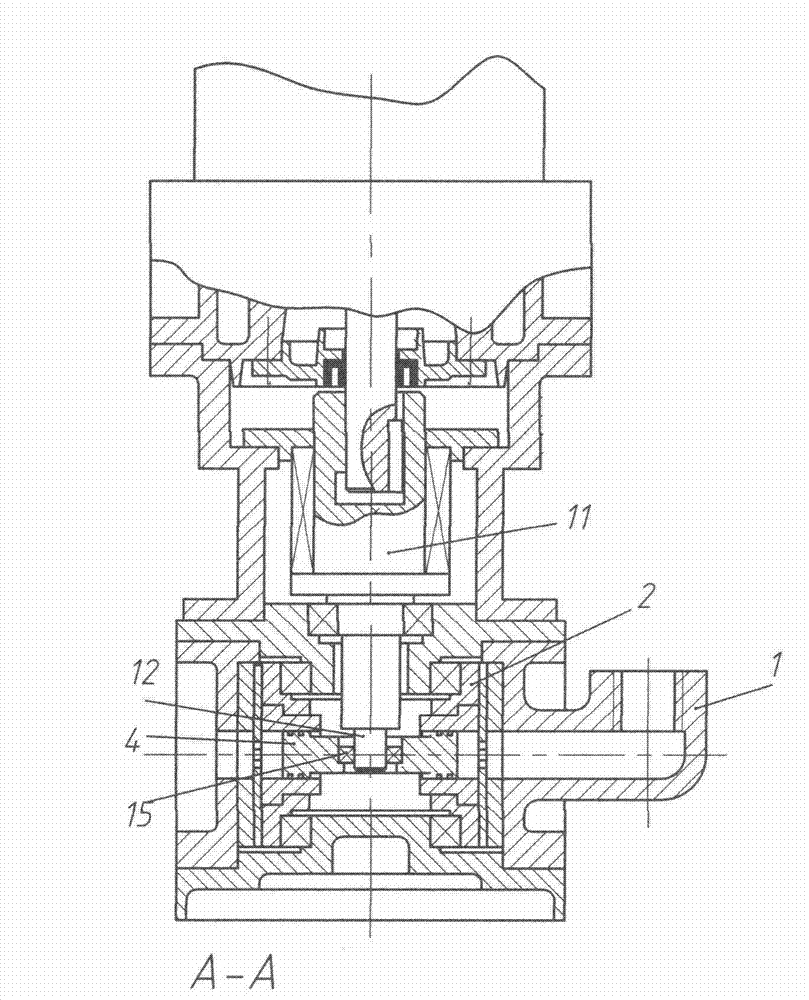

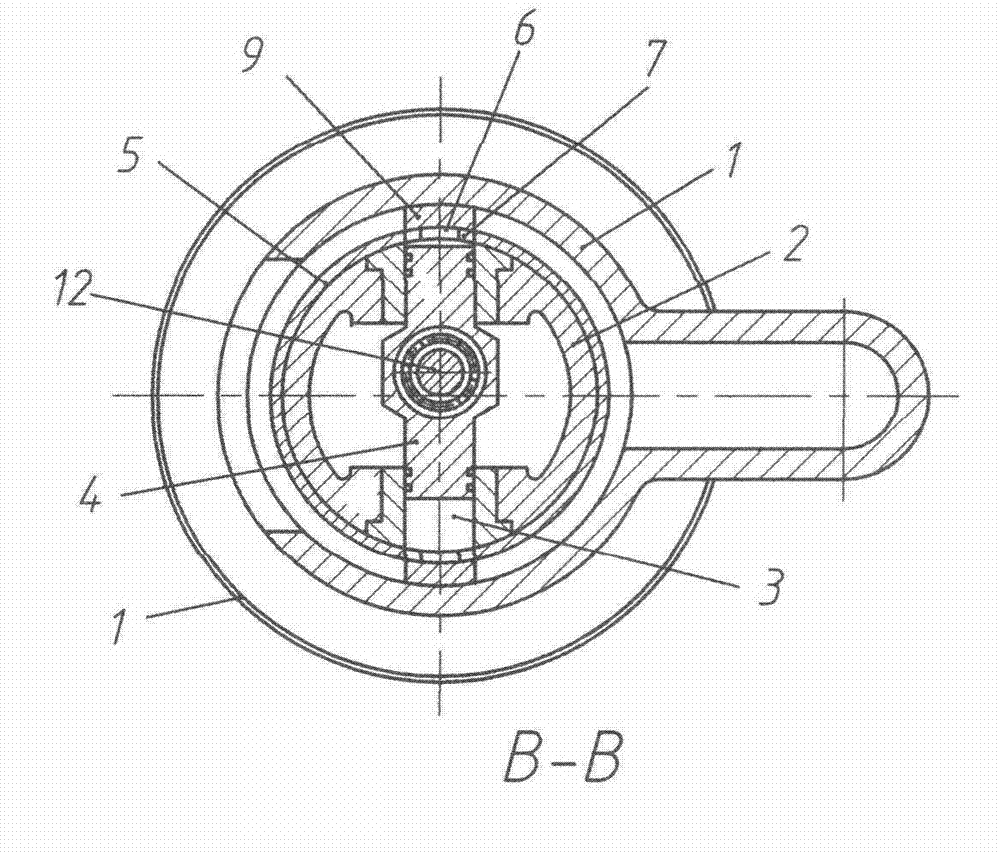

[0015] figure 1 is a structural diagram of an embodiment of the present invention, figure 2 Yes figure 1 A-A sectional view of, image 3 Yes figure 1 The B-B section view.

[0016] The figure shows that the rotor submersible pump directly connected with the eccentric shaft and the motor includes a pump body 1 with a suction port and a discharge port, a rotor 2 installed in the inner cavity of the pump body 1 and coaxial with it, and the rotor 2 is composed of two rolling bearings. 15 support, the rotor 2 is formed with at least one row of radial through holes 3, and the radial through holes 3 are equipped with a piston 4 capable of reciprocating movement by means of an eccentric mechanism; a rotor sleeve 5 is fixed on the outer circle of the rotor 2, and the rotor sleeve 5 A radial hole 6 with a smaller diameter coaxial with the radial through hole 3 of the rotor 2 is opened on the top, and narrow grooves 7 communicating with the radial hole 6 are formed on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com