Drilling and punching integrated hydraulic drill bit

A technology of hydraulic punching and drilling bits, which is applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of no secondary crushing capacity, clogging of slag discharge channels, uneven coal output, etc., achieving simple structure and preventing hole jamming , the effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

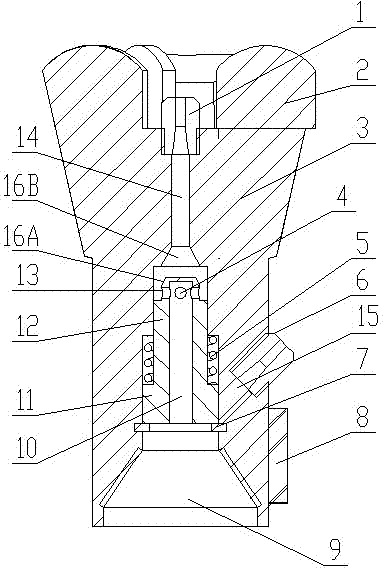

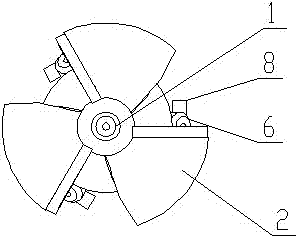

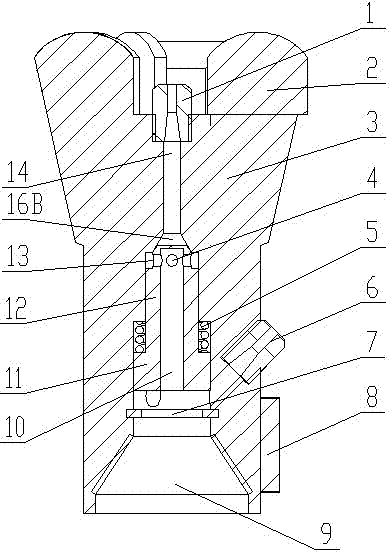

[0015] Depend on Figure 1-Figure 3 The shown drilling-punching integrated hydraulic punching drill includes a drill body 3 extending forward and backward. The front end of the drill body 3 is provided with blades 2, and the blades 2 are evenly spaced around the central axis of the drill body 3. The blade 2 is provided with a cemented carbide blade. An axially extending through hole is provided throughout the drill bit body 3 , the axis of the through hole is the central axis of the drill bit body 3 , and the through hole also extends forward and backward. The through hole includes a nozzle hole portion 14 located in the front section, a valve body hole section located in the middle section and a reaming part 9 located in the rear section, and the reaming part 9 is a tapered threaded hole expanding outward on the rear side. The nozzle hole part 14 is a cylindrical hole, the rear port of the nozzle hole part 14 is a tapered opening 16B, and the tapered threaded hole of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com