Impeller structure of rotary shell type pump

A technology of impeller and rotary casing, which is applied in the field of pump impeller structure, can solve problems such as unstable operation, impact loss, hydraulic loss, etc., and achieve the effects of low roughness, guaranteed dimensional accuracy, and guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

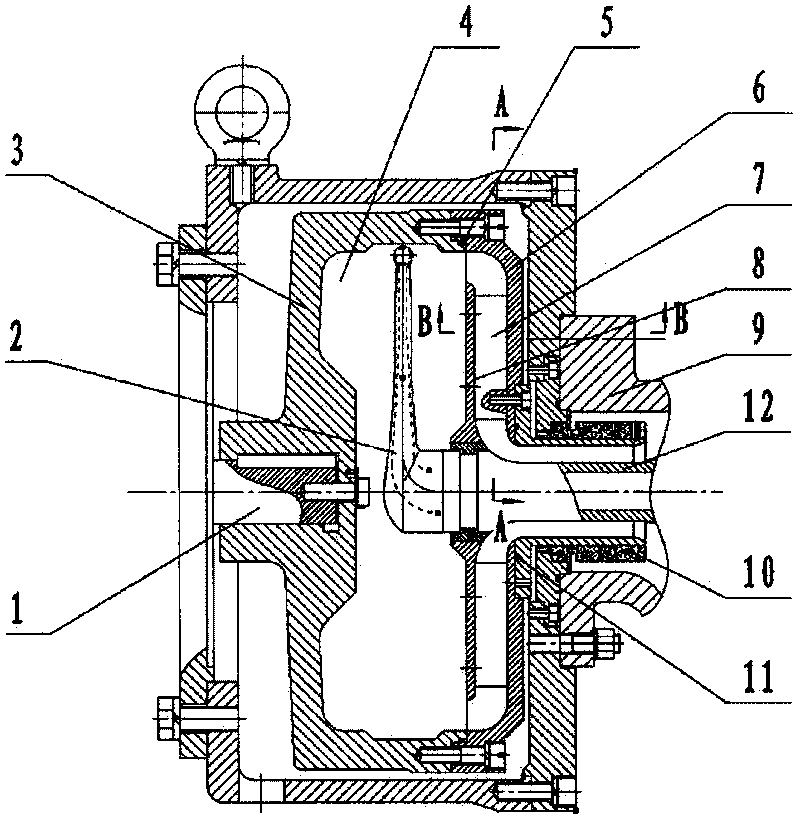

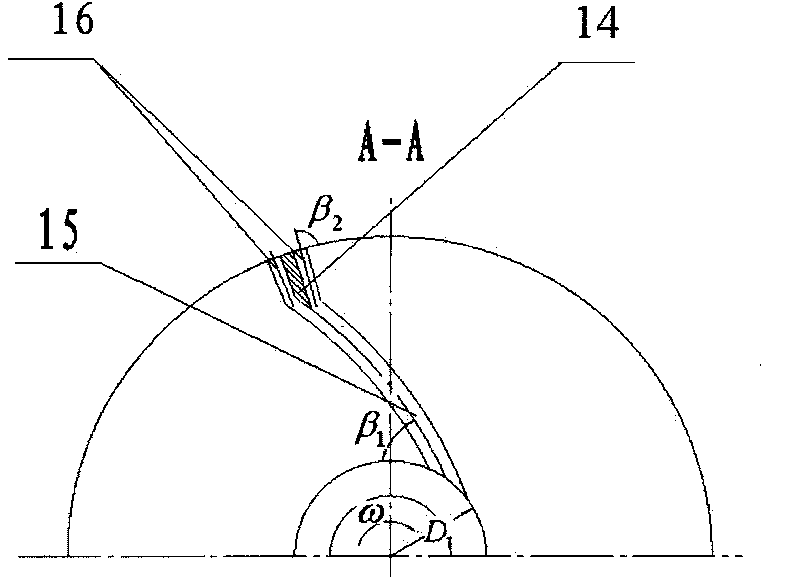

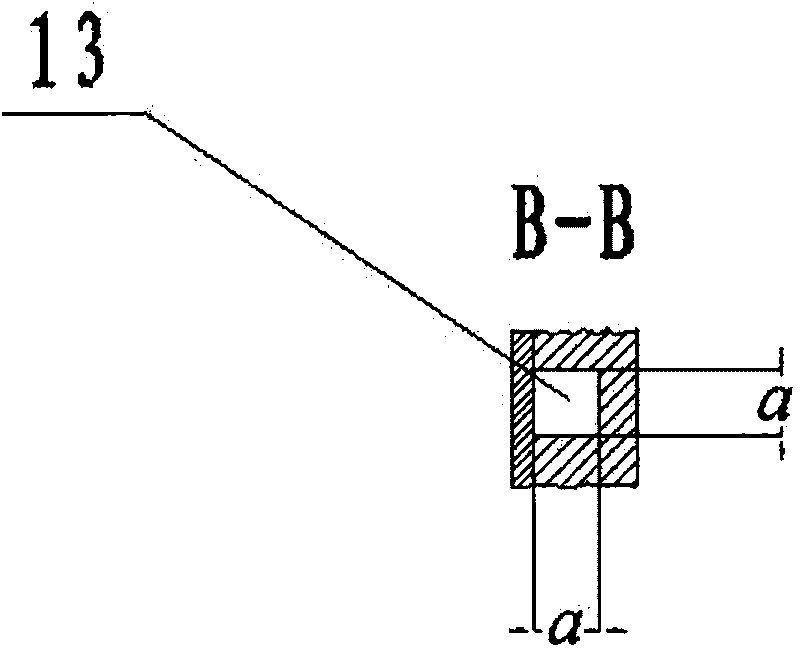

[0018] A high-efficiency rotary shell pump impeller structure includes impeller blades located between a front cover plate 6 and a rear cover plate 8. Adjacent impeller blades form an impeller flow channel 7, and the impeller flow channel 7 and the front cover plate 6 are integrated. The impeller suction section 9, the front cover 6 and the rear cover 8 can all use casting blanks. The material can be cast iron or cast steel according to the design parameters. Most of the petrochemical industry uses stainless steel. Both the rear cover 8 and the suction section 9 can reach the size required by the design through a gold processing method. The front cover 6 is the main body of the impeller. The outer diameter of the impeller outlet is calculated according to the design flow, head and speed, as well as the number of impeller runners 7 and the cross-sectional dimensions of the runners. According to the inlet runner size a, the inlet of the runner is initially determined The diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com