Water turbine draft tube with vortex restraining function

A draft tube and vortex technology, which is applied in the field of hydraulic turbine draft tubes, can solve problems affecting the safe operation of hydropower units, and achieve the effects of improving energy conversion efficiency, improving pressure pulsation, and suppressing vortexes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principle, structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

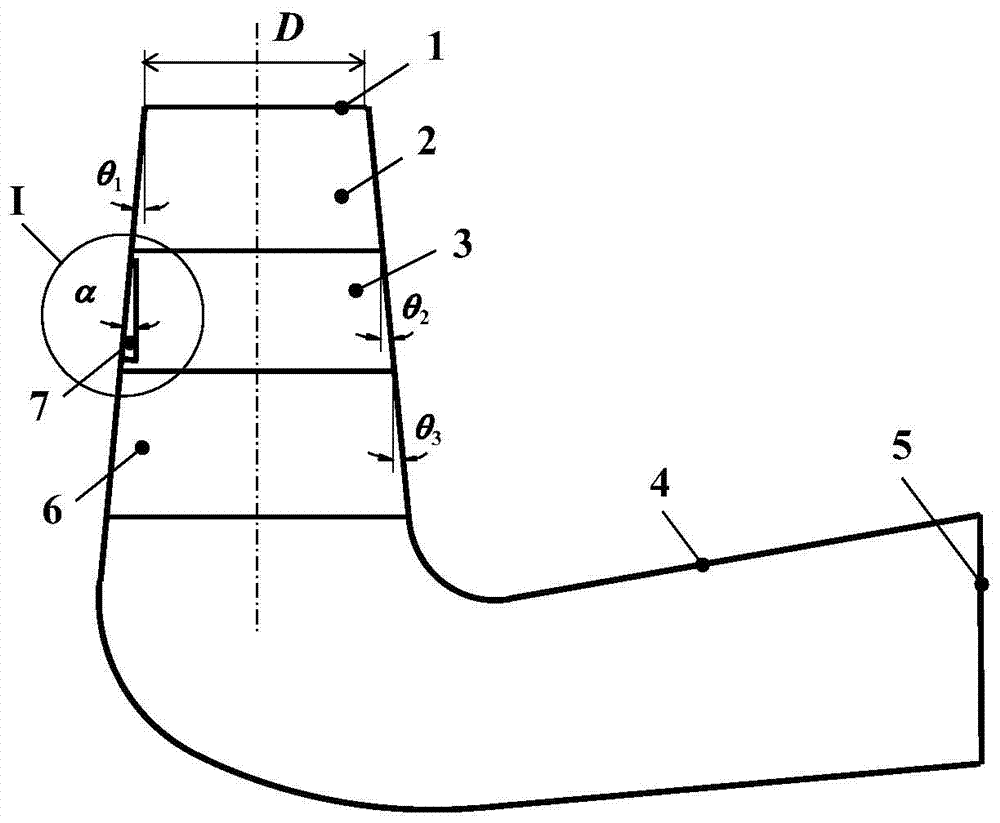

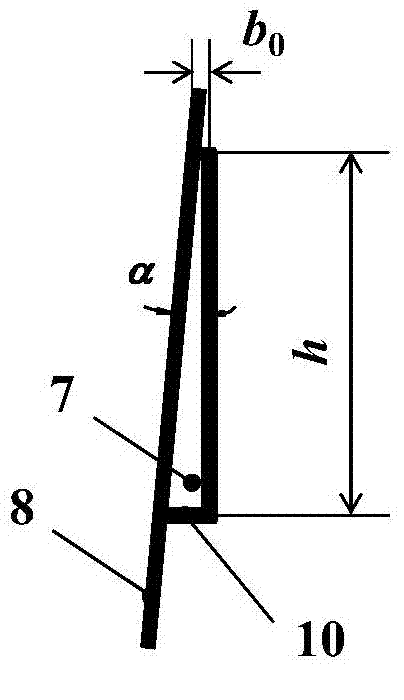

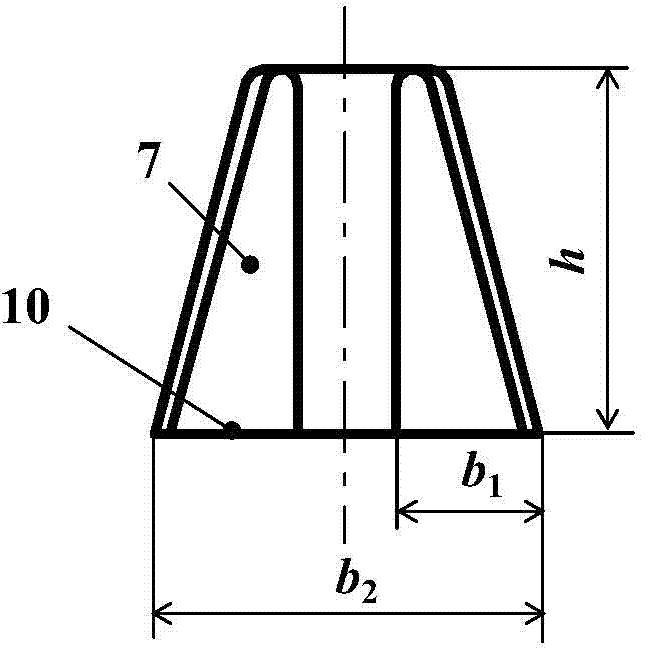

[0017] figure 1 The main cross-sectional view of the draft tube of the hydraulic turbine with the vortex suppression device provided by the present invention, the draft tube of the hydraulic turbine includes the draft tube inlet 1, the upper conical section 2, the middle conical section 3, the lower conical section 6, the elbow section 4 and the draft tube outlet 5 , the middle cone section 3 is set between the upper cone section and the lower cone section, the three cone sections are arranged on the same axis, and the half cone angles of the upper cone section 2, the middle cone section 3 and the lower cone section 6 are respectively θ 1 , θ 2 and θ 3 . At least one vortex suppressing device 7 is arranged along the circumferential direction on the inner wall surface 9 of the middle cone section, preferably 2 to 6 piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com