Cyclone pump impeller with spiral structure at front end and design method thereof

A technology of helical structure and design method, which is applied to the components, pumps, and pump elements of pumping devices for elastic fluids, can solve the problems of low efficiency and large hydraulic loss of the pump, and achieves reduction of energy loss and improvement of work efficiency. The effect of efficiency and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

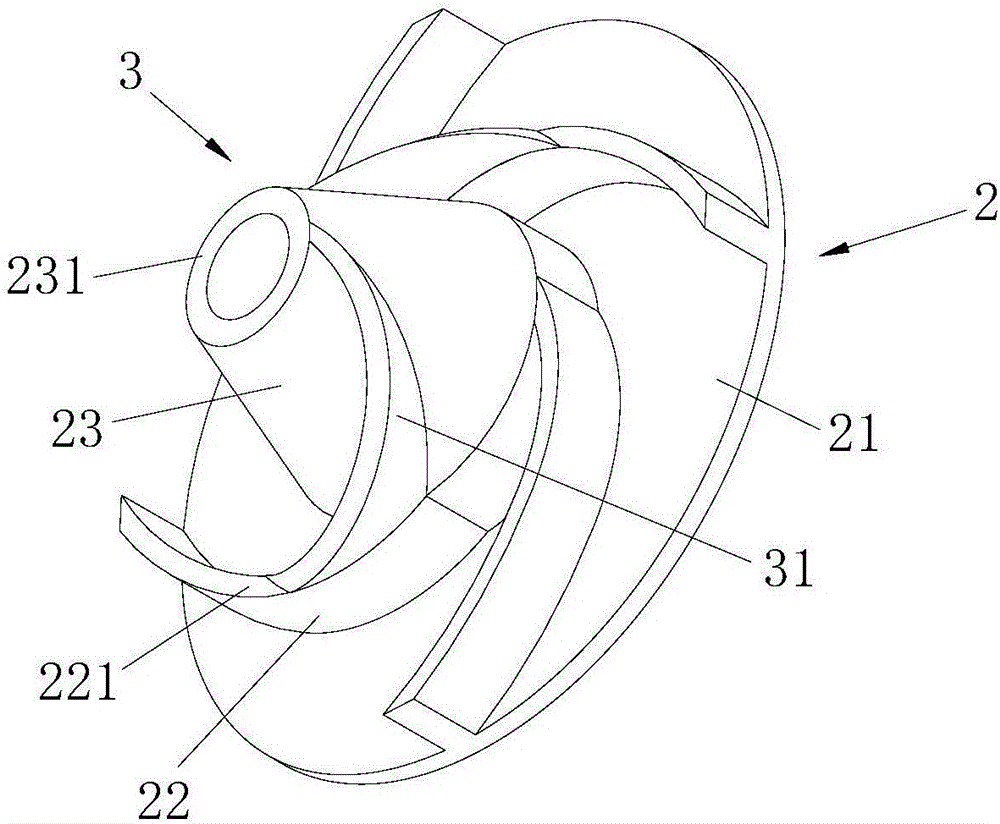

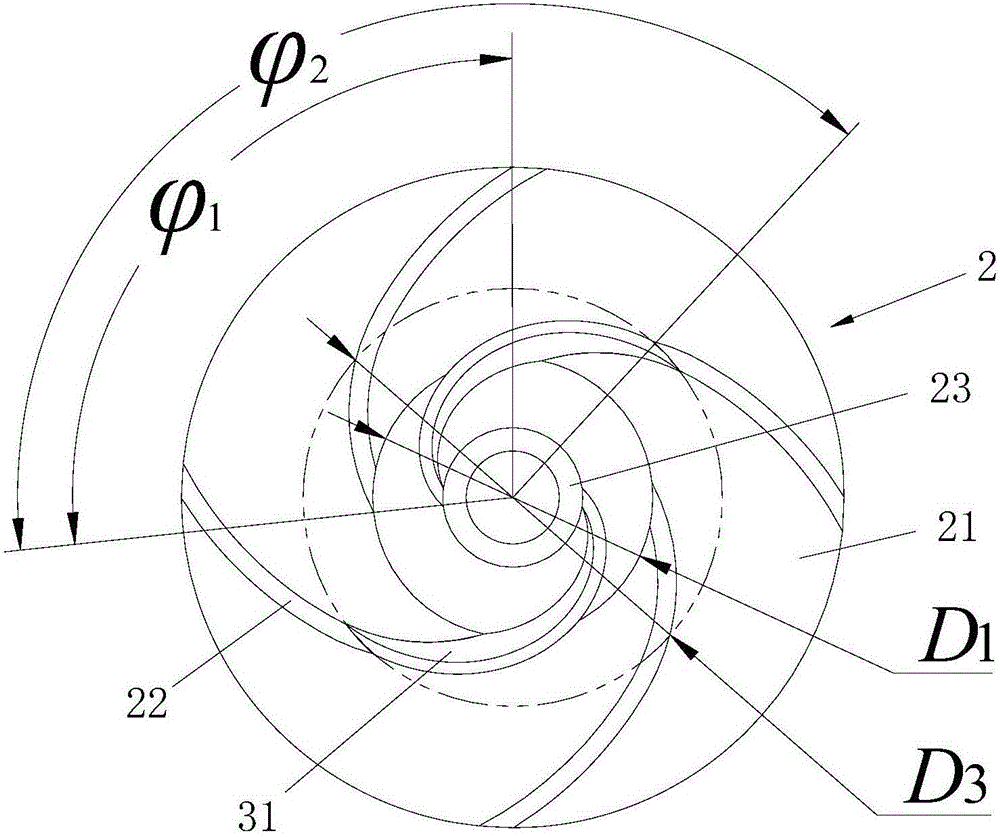

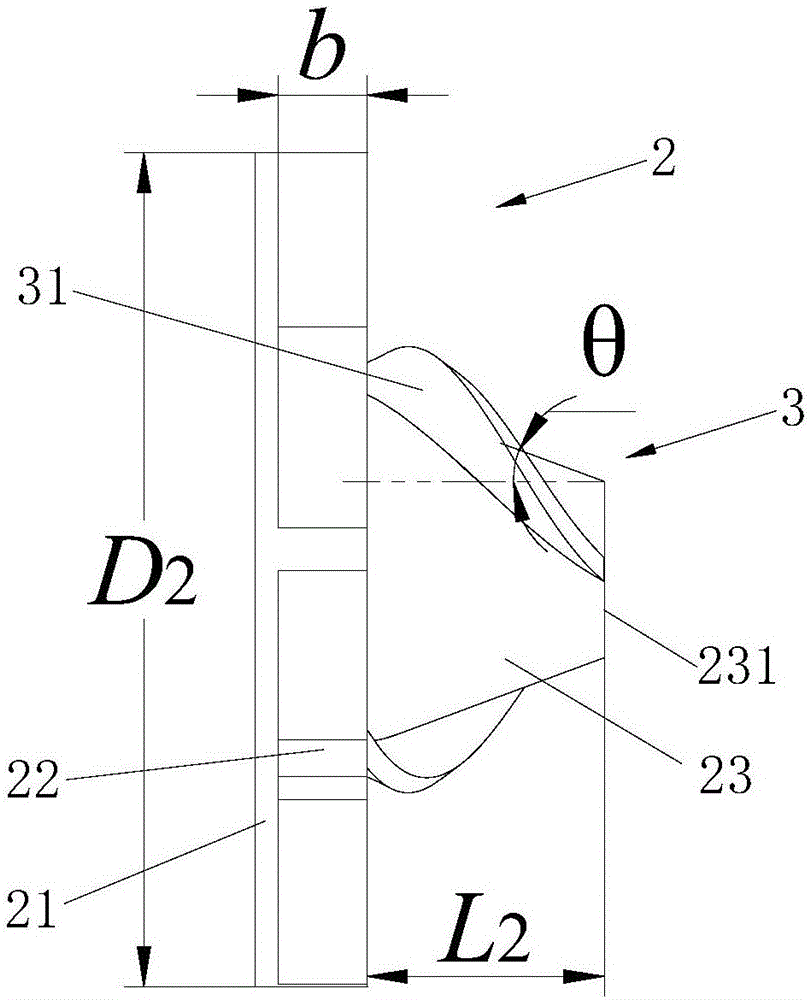

[0050] Embodiment one: if Figure 1-6 As shown, this embodiment includes a swirl pump impeller 2 and a volute 1 with a vane cavity 11. The swirl pump impeller 2 is a semi-open impeller, and the semi-open impeller includes a front cover plate 21, impeller blades 22 and a hub. 23; The part of the volute 1 far away from the front cover 21 is provided with a vane cavity opening 12, the semi-open impeller is installed in the vane cavity 11, and the part of the hub 23 far away from the front cover 21 is the hub front end 231, and the hub front end 231 It is set toward the opening 12 of the blade cavity, and the distance between the front end 231 of the hub and the opening 12 of the blade cavity is L 1. The outer surface of the wheel hub 23 is a truncated cone structure (or called a truncated cone structure). The area of the upper bottom surface of this truncated circular structure is less than the area of the lower bottom surface, so the wheel hub 23 is fixed with the front cov...

Embodiment 2

[0080] Embodiment 2: The molded line of the helical blade 31 is a helical line, and the helical line takes the center of the lower bottom surface of the hub 23 as the origin, and establishes a three-dimensional coordinate system, wherein the x-axis and the y-axis are located on the lower bottom surface, and the z-axis direction is perpendicular to x Axis and y-axis, and consistent with the hub 23 axis direction, if the starting point of the spiral blade 31 is point A, the end point of the spiral blade is point B, and the coordinates of point A are ( 0, L2), the coordinates of point B are ( 0), any point on the space curve connecting point A and point B is point C, the projection of point C on the bottom surface is C', the line connecting C' and the origin is OC', and the clip between OC' and the positive direction of the x-axis Angle is Then the coordinates of point C are In the formula:

Embodiment 3

[0081] Embodiment 3: The number of helical blades 31 is equal to the number of impeller blades 22 , and the front end of each impeller blade 22 is provided with helical blades 31 in one-to-one correspondence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com