Turbo-compound system

A technology of turbo compound and power turbine, applied in clutch, clutch, fluid clutch, etc., can solve the problems of strong torque dependence, inability to apply uniform braking torque to the crankshaft, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

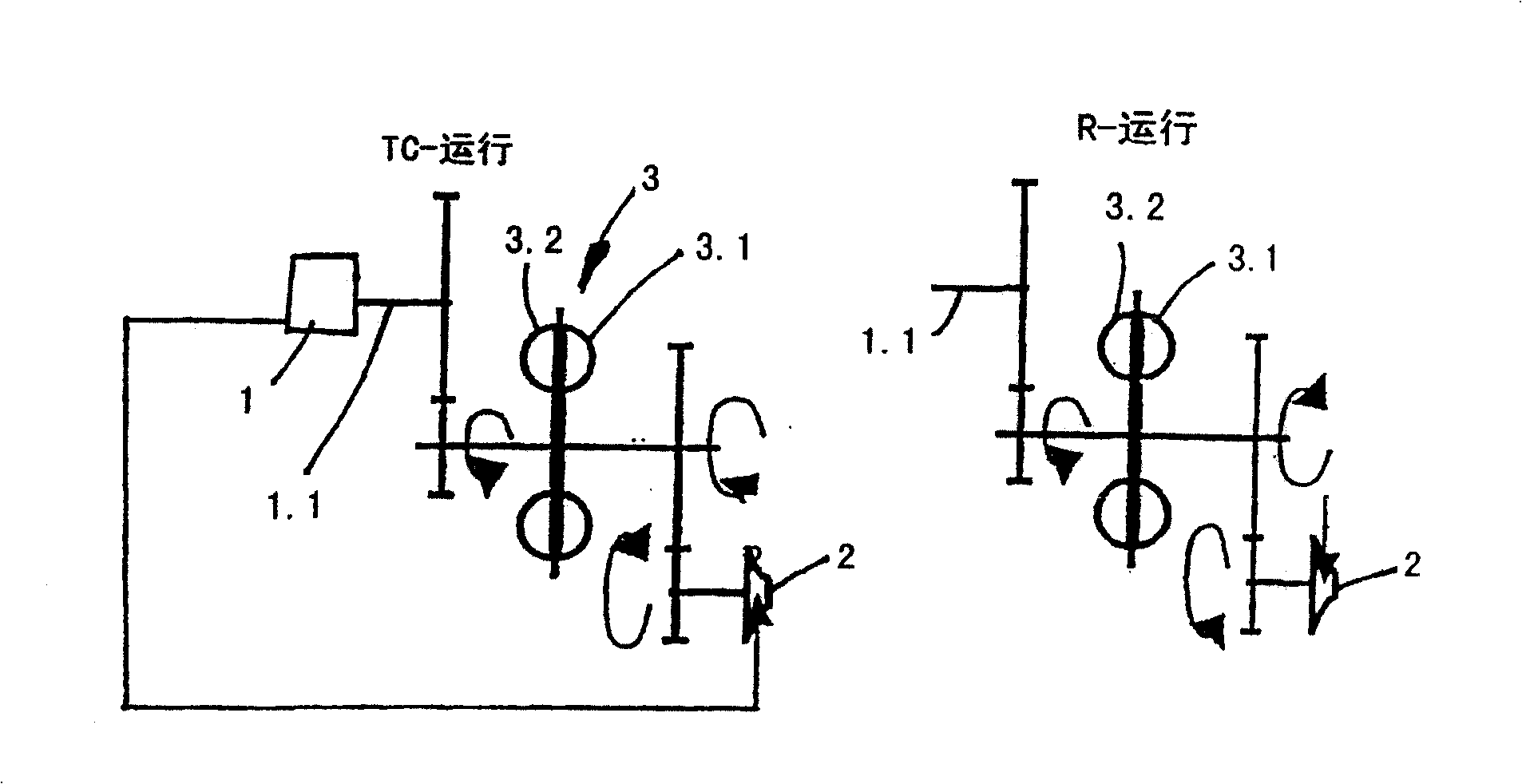

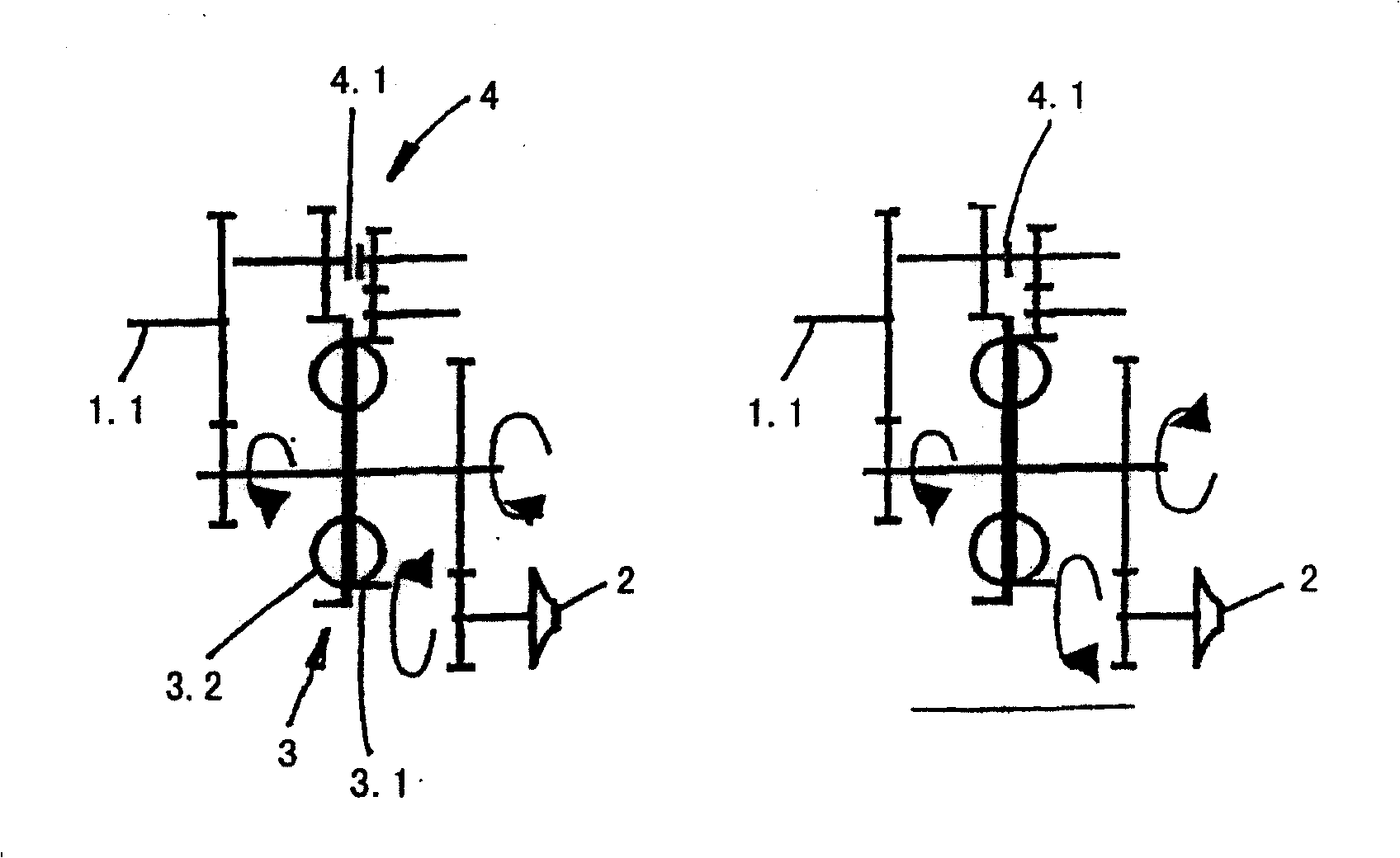

[0020] figure 1 represents a turbocompound system according to the invention, in which there is an internal combustion engine 1 , during turbocompound operation, the crankshaft 1 . The fluid coupling working chamber between the second wheel and the second wheel 3.2 is filled with working medium. On each side of the hydrodynamic coupling 3 there are speed shifting gears between the crankshaft 1.1 and the second wheel 3.2 and between the exhaust gas turbine 2 and the first wheel 3.1. As shown, in turbocompound operation, the targeted supply of exhaust gas flow to the exhaust gas turbine or to the turbine wheel of the exhaust gas turbine via a guide grid causes the first wheel 3.1 of the fluid coupling to rotate in a first direction of rotation.

[0021] On the contrary, in the operation of the reducer, the leading exhaust gas flow is changed relative to the operation of the turbocompound by reversing the direction of rotation of the exhaust gas turbine 2, whereby the first whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com