Compact type annular axial high accuracy positioning and clamping mechanism, and using and manufacturing method thereof

A positioning and clamping, high-precision technology, applied in the direction of manufacturing tools, gear teeth manufacturing devices, gear cutting machines, etc., can solve the problems of small braking torque, low positioning and clamping accuracy, and low reliability, and achieve positioning and clamping accuracy High, simple and compact structure, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

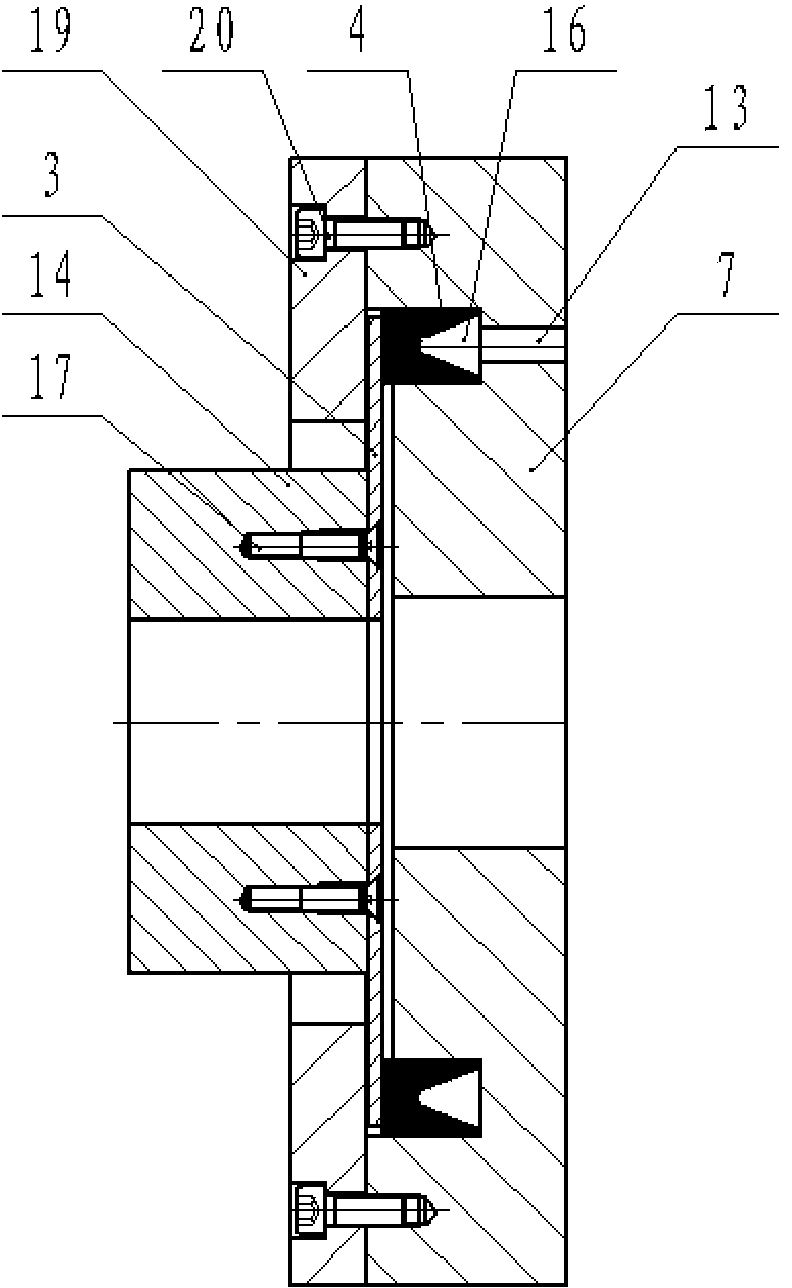

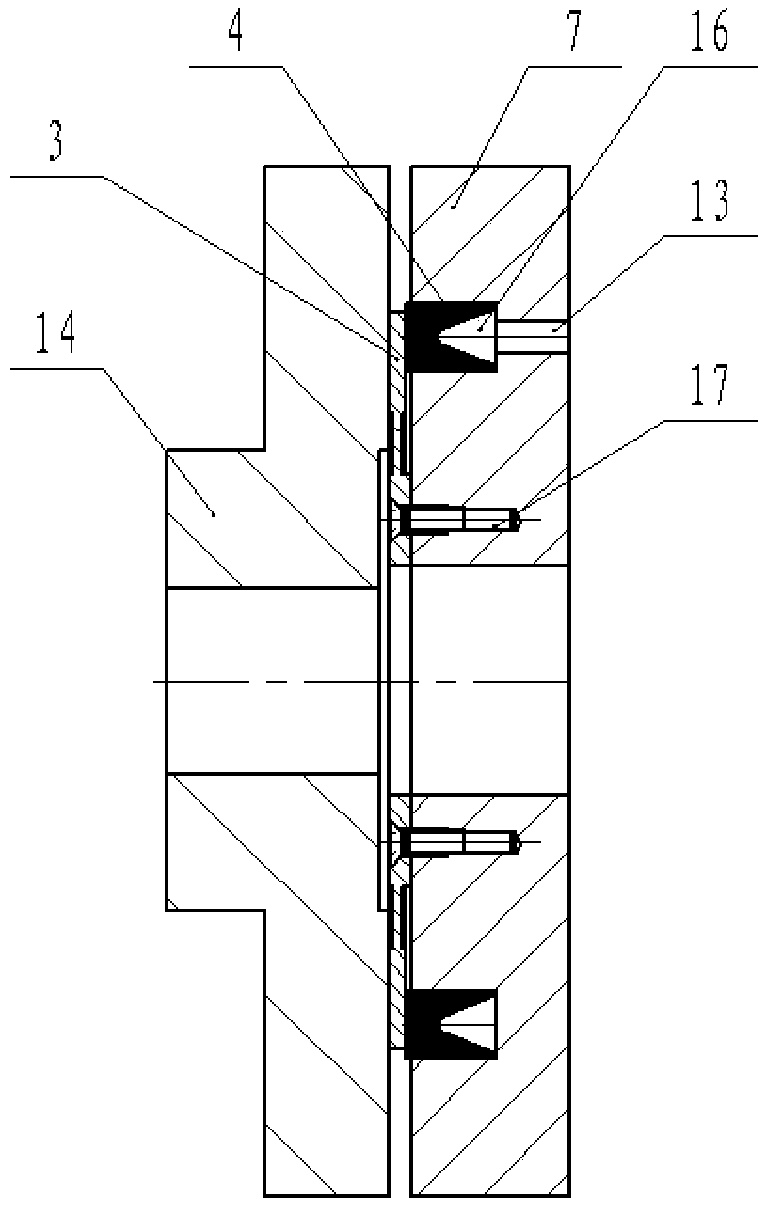

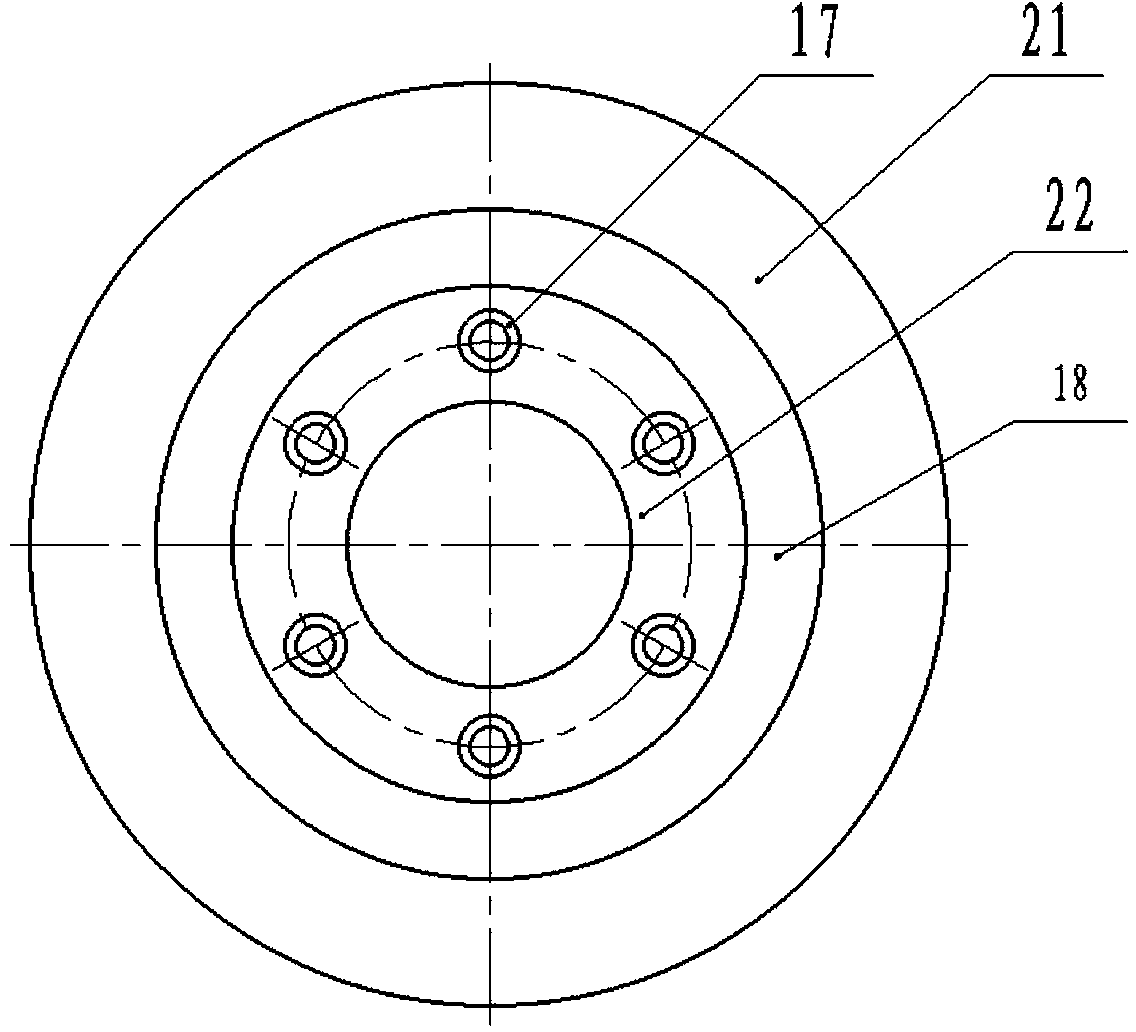

[0036] The invention discloses a compact annular axial high-precision positioning and clamping mechanism. The positioning and clamping mechanism includes a base, a sealing ring, an annular clamping disc and a rotator, and the annular clamping disc is fixed on the base with countersunk screws. Above, the revolving body can be directly driven by the power components or driven by the transmission mechanism. When the revolving body is positioned and stopped at any angle position, the medium liquid (gas) can be pressed into the annular sealing cavity from the liquid (gas) inlet (by the sealing ring And the annular groove opened on the base), the liquid (gas) pressure forces the sealing ring to produce a certain displacement in the axial direction of the rotary body, and the axial force acts on the annular surface of the annular clamping disc evenly, The outer ring surface of the ring clamping disc is subjected to pressure to produce axial deformation, and the deformed part of the ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com