Hydraulic motor integrating wet brake

A technology of wet brakes and hydraulic motors, applied in the field of hydraulic motors, can solve the problems of poor braking effect, complex structure, exposed braking working surface, etc., and achieve the effects of normal operation and less heat generation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

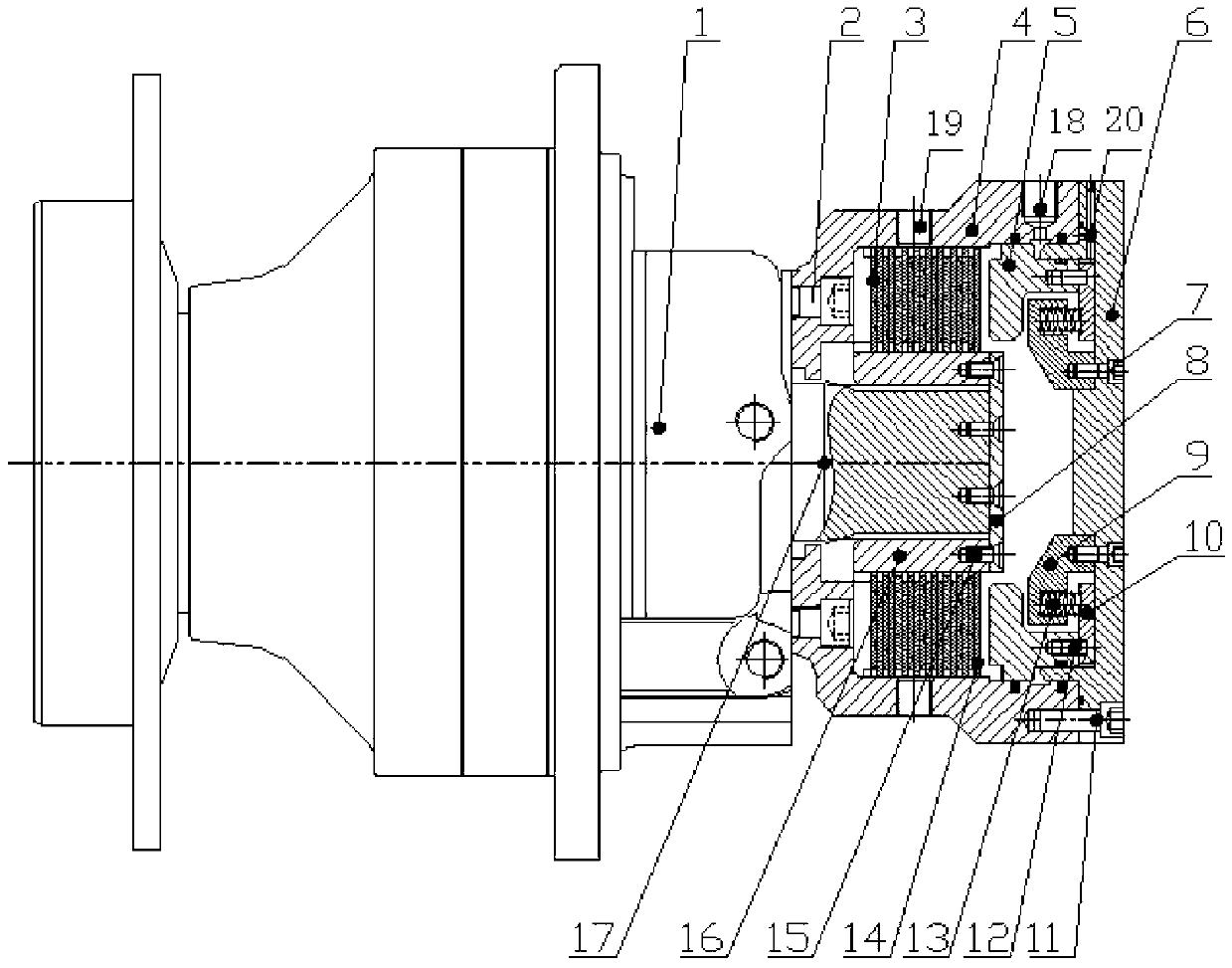

[0025] refer to figure 1 , a hydraulic motor integrating a wet brake, including a hydraulic motor body 1 and a brake body, the brake body is arranged at the tail of the hydraulic motor body 1, the brake body includes a brake housing 4 and a brake housing 4 Brake piston 5, active friction plate 3, driven friction plate 14, return spring 13, first return spring base 9, second return spring base 10 and transition disc 16, the front end of the brake housing 4 is connected to the main body of the hydraulic motor 1 connected by the first nut 2, the rear end of the brake housing 4 is provided with a brake rear cover 6 matching the brake housing 4; the brake housing 4 is provided with a brake oil port 18;

[0026] The internal teeth of the transition plate 16 mesh with the external teeth of the transmission shaft 17 of the hydraulic motor main body 1, the active friction plate 3 and the driven friction plate 14 are respectively arranged on both sides of the transition plate 16, the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com