Treatment technology of emulsion contained spent water

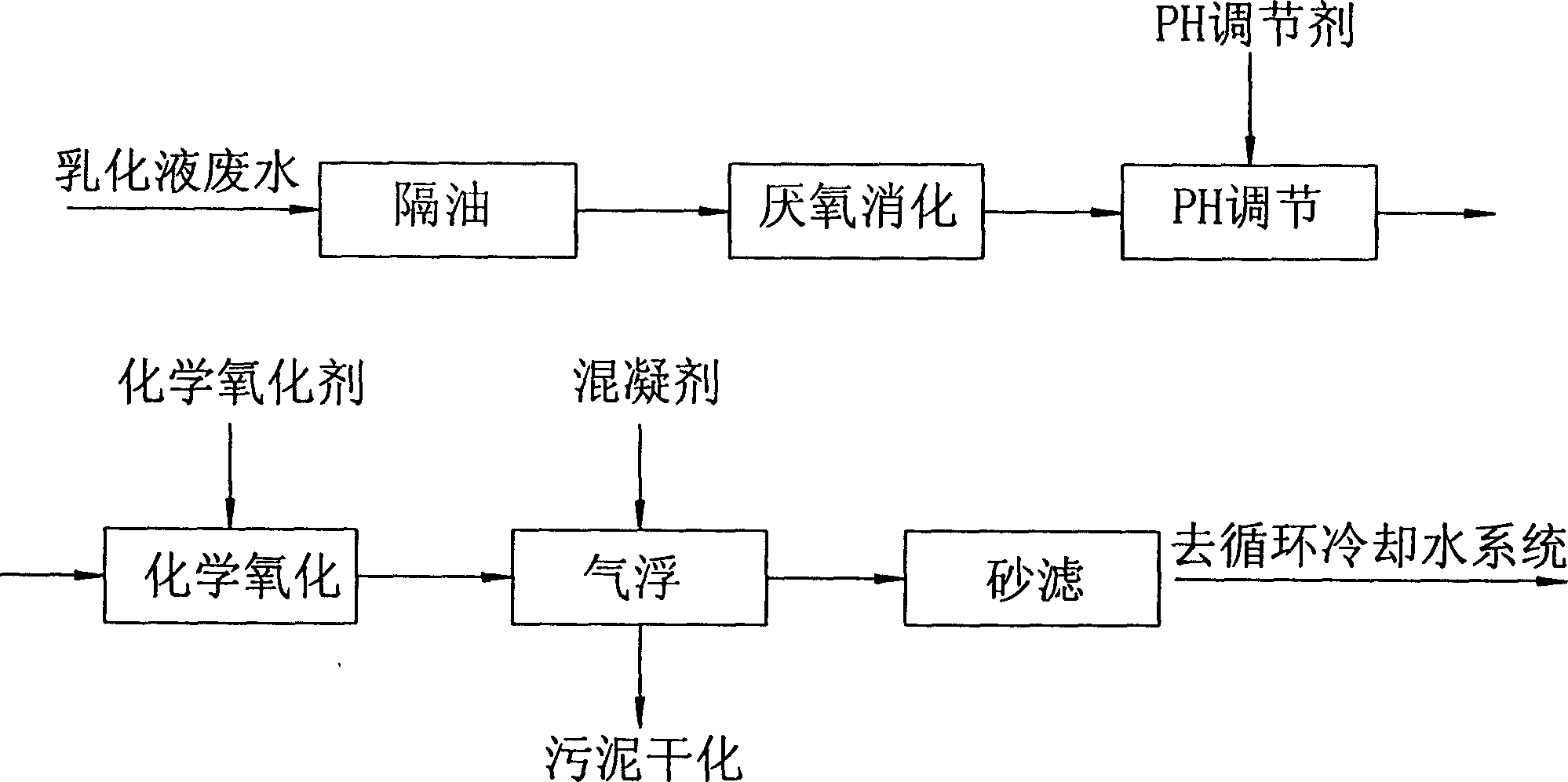

A treatment process and emulsion technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficult to effectively remove, large floor space, and large equipment investment , to achieve the effect of simple operation, small equipment footprint and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Take a plant that treats 100 tons of emulsion wastewater per day as an example:

[0041] (1). The emulsion-containing waste water generated during the operation of the machine is used in the grease trap to remove the machine oil in a suspended state by the oil collection device. The oil-collecting device relies on an oil-friendly and hydrophobic ring-shaped oil-collecting drag, which is mechanically driven to continuously rotate on the oil-water surface at a certain speed to adhere the oil from the oily sewage, and squeeze the oil through the squeeze roller. Squeeze into the oil collection drum;

[0042] (2). After removing the oil slick, the wastewater enters the anaerobic tank and stays for 12 to 24 hours. Under the action of anaerobic microorganisms, the organic matter is digested and degraded, and the emulsifier is destroyed or partially destroyed and decomposed;

[0043] (3). After anaerobic digestion, the wastewater enters the oxidation reaction tank. First add l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com