Method and product for improving microchannel plate soft X-ray-extreme ultraviolet ray imaging performance

A micro-channel plate, extreme ultraviolet technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as low reflectivity of soft X-rays, achieve high repeatability, uniform thickness, The effect of enhancing feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Relevant technical content of the present invention and explanation, cooperate accompanying drawing to set forth as follows now:

[0039] The atomic layer deposition equipment used in the present invention is TFS-200 provided by Beneq Company of Finland.

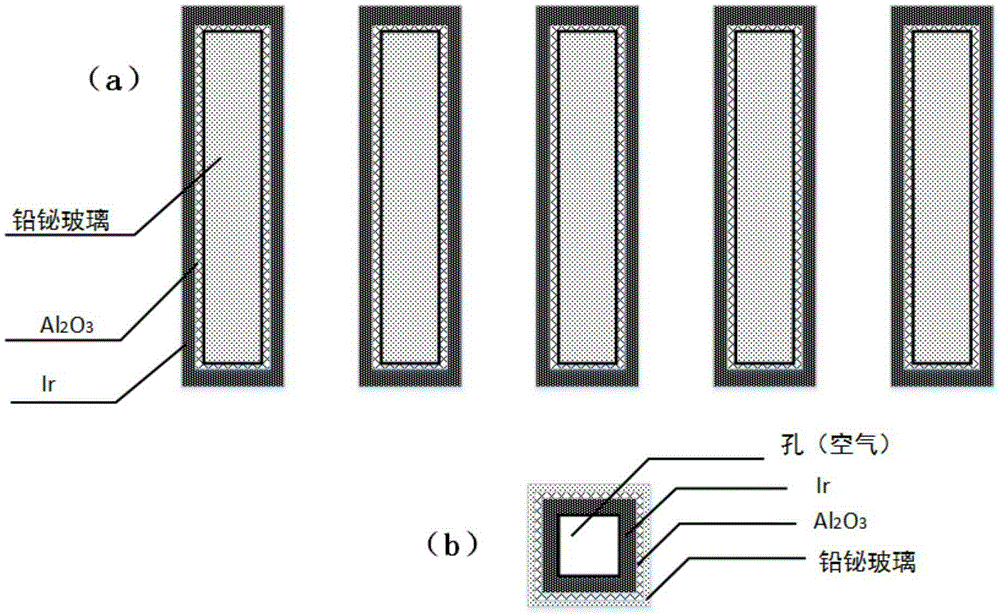

[0040] In order to enhance the adsorption of iridium film without affecting the reflection characteristics of iridium to X-rays, first coat an aluminum oxide film with a thickness of about 10nm:

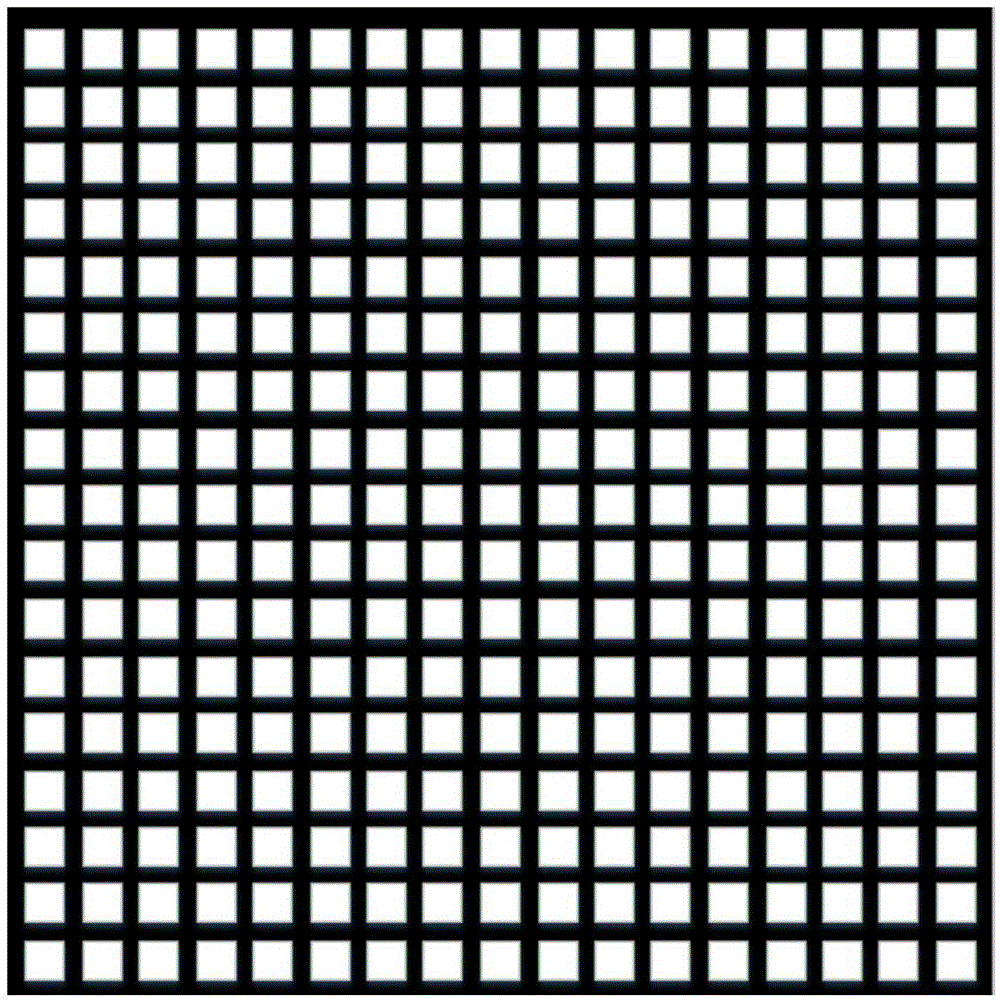

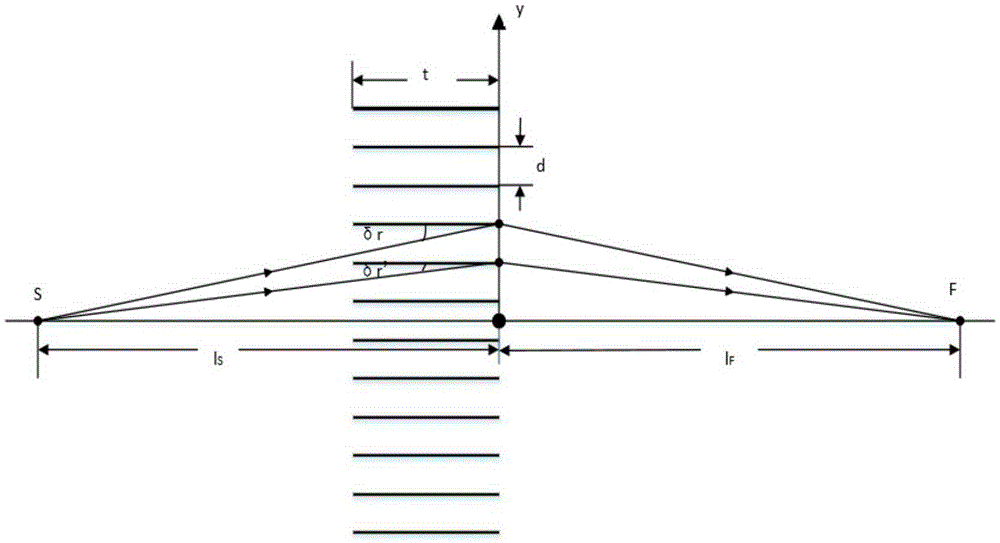

[0041] The first step: the microchannel plate made of lead-bismuth glass is used as the substrate, and the structure is as follows figure 1 As shown, after the fixture is fixed, it is put into the reaction chamber, and the reaction chamber is evacuated to a vacuum state. Due to equipment problems, the reaction chamber can only reach a low vacuum environment, and the vacuum degree is about 6mbar;

[0042] The second step: according to the process requirements of alumina film growth, the temperature of the reaction chamber i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com