Pressurizing cylinder

A technology of pressurizing cylinder and cylinder barrel, which is applied in the hydraulic field and can solve problems such as small pressurization ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The invention will be described in detail below in conjunction with the accompanying drawings.

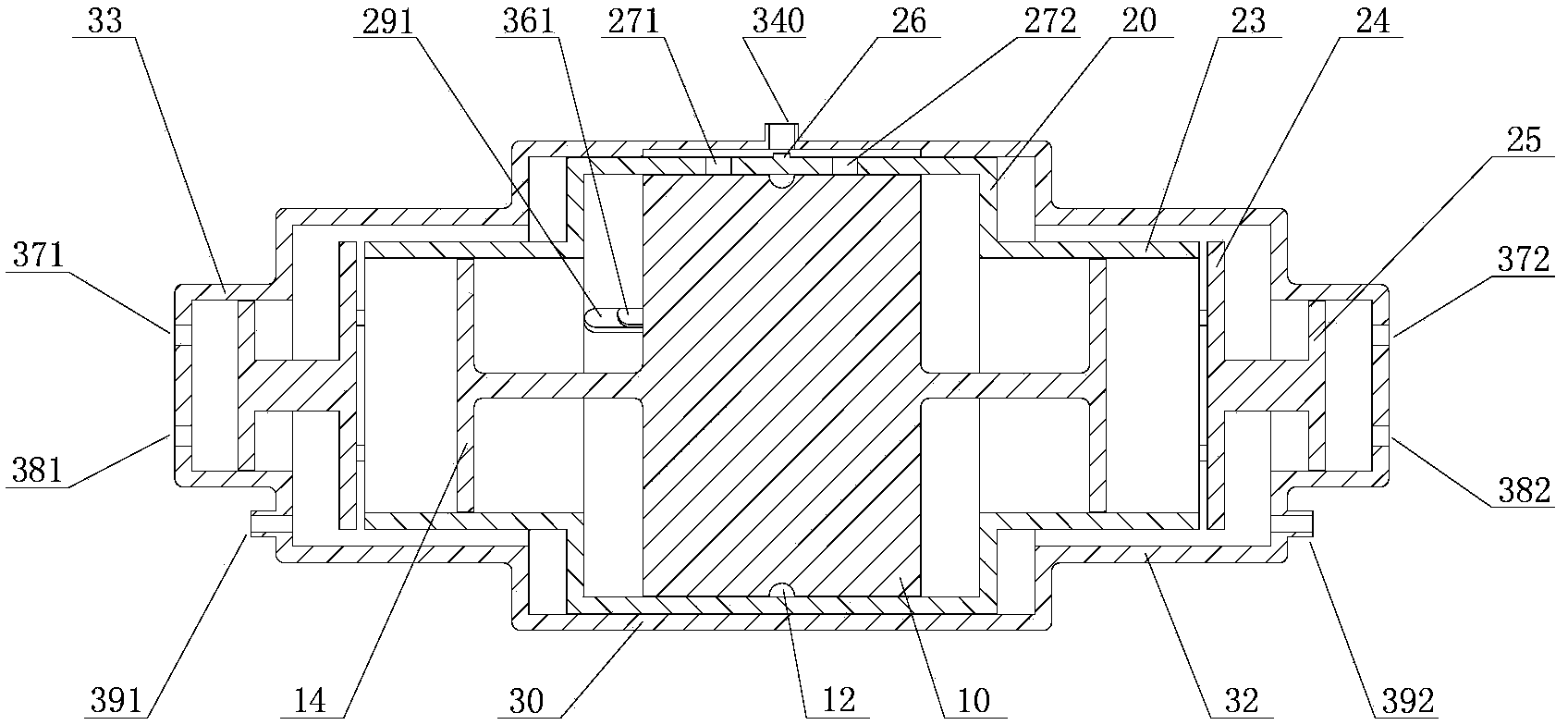

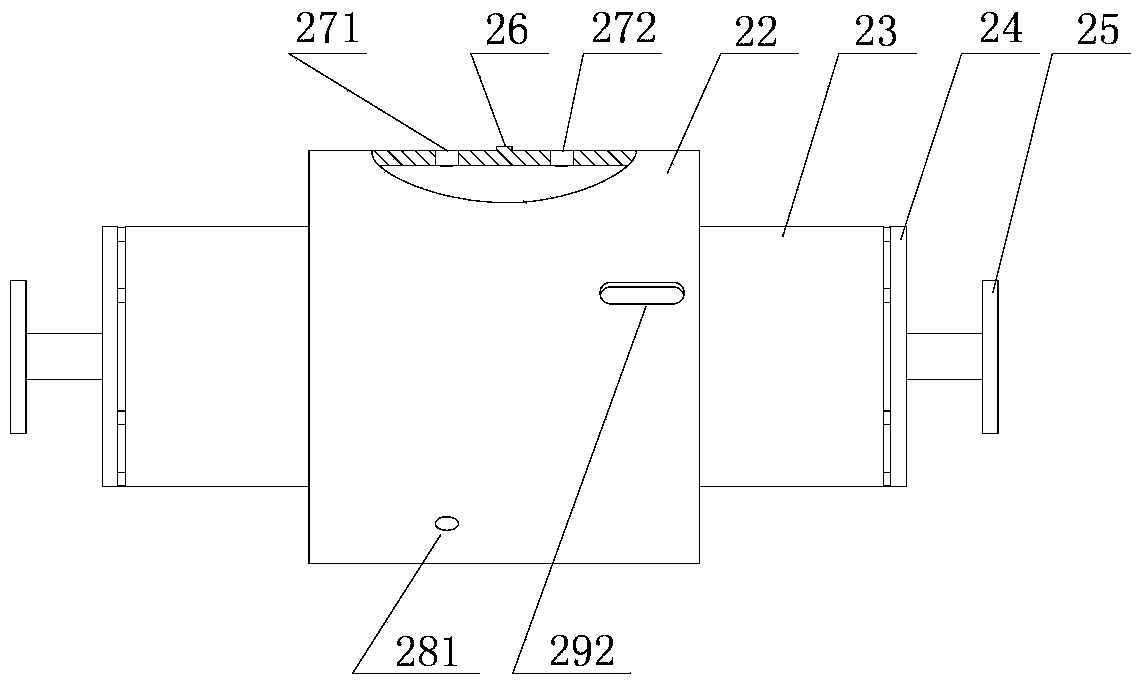

[0049] like figure 1 As shown, a booster cylinder includes three parts: a primary piston 10, a secondary piston 20 and a cylinder barrel 30. The primary piston 10 is set in the inner cavity of the secondary piston 20, and the secondary piston 20 is set in the cylinder barrel 30. The inner chamber of the first stage piston 10 and the second stage piston 20 move with each other to complete the first pressurization of the hydraulic oil; the relative movement of the second stage piston 20 and the cylinder barrel 30 completes the second pressurization of the hydraulic oil.

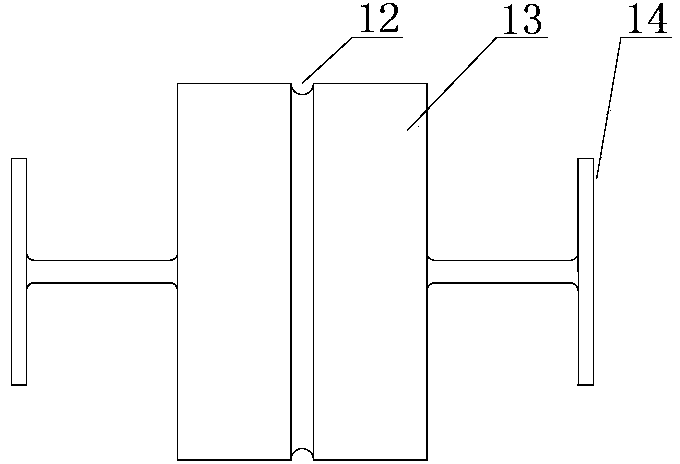

[0050] like figure 2 As shown, the primary piston 10 includes a main body, the main body is a cylinder 13 with an annular groove 12 on the circumferential surface, and a disc 14 is respectively formed on the two ends of the cylinder 13, the circle Area A of disc 14 14 less than the cross-sectional area A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com