Threaded self-locking type automatic centering work fixture used for annular workpiece

A ring workpiece, automatic centering technology, applied in the field of clamping device, threaded self-locking fixture, can solve the problems of difficult disassembly, chuck wear, heavy weight, etc., to achieve convenient operation, long service life, simple and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

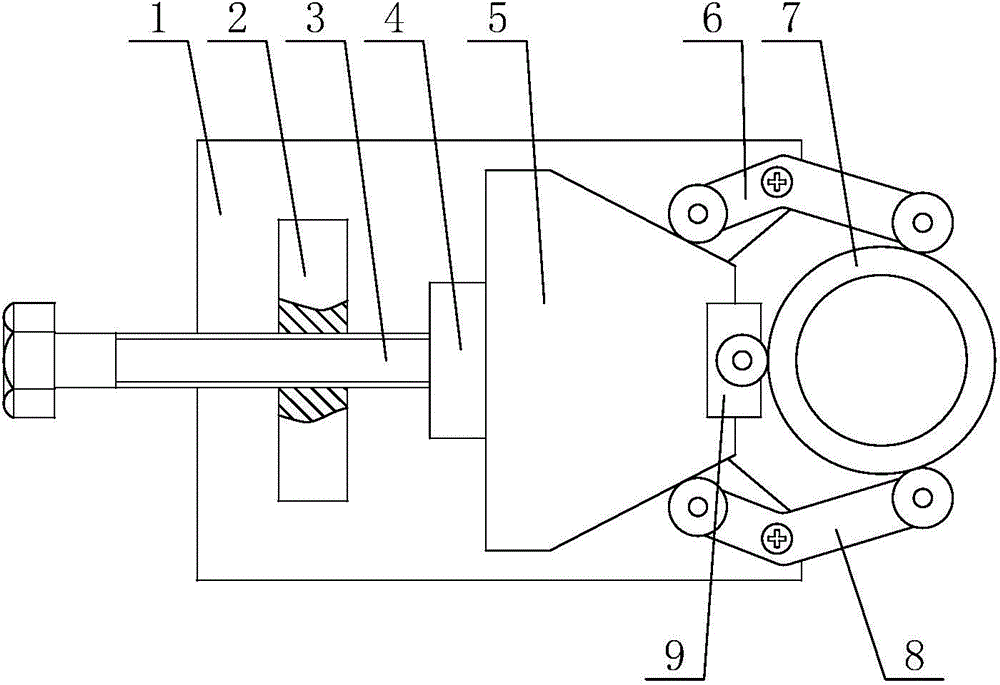

[0019] like figure 1 A threaded self-locking automatic centering tooling fixture for an annular workpiece as shown, includes a base plate 1 with a V-shaped groove at one end, and a bending arm 6 and a folding arm 6 that cooperate with each other to clamp the annular workpiece 7 from the outside. Bending arm 2 8, the inclined-plane pushing head 5 used to tighten the annular workpiece 7 in cooperation with the bending arm 1 6 and the bending arm 2 8, the drive screw for driving the inclined-plane pushing head 5 to move back and forth 3 and the screw seat 2 that cooperates with the driving screw 3 to form a thread transmission pair; the upper side of one end of the bottom plate 1 is rotatably installed with the bending arm one 6 and the bending arm two 8 that are symmetrical to each other, and the bottom plate 1. The screw seat 2 is fixedly installed on the upper side of the other end, and the drive screw 3 is installed on the screw seat 2 through a threaded hole. The rear end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com