Booster for servo press

A technology of servo press and booster device, which is applied in the field of forging machinery, can solve the problems of inability to realize multi-point output, unchanged booster ratio, increase the difficulty and cost of press control, and achieve simple structure and large booster ratio , Improve the effect of anti-eccentric load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

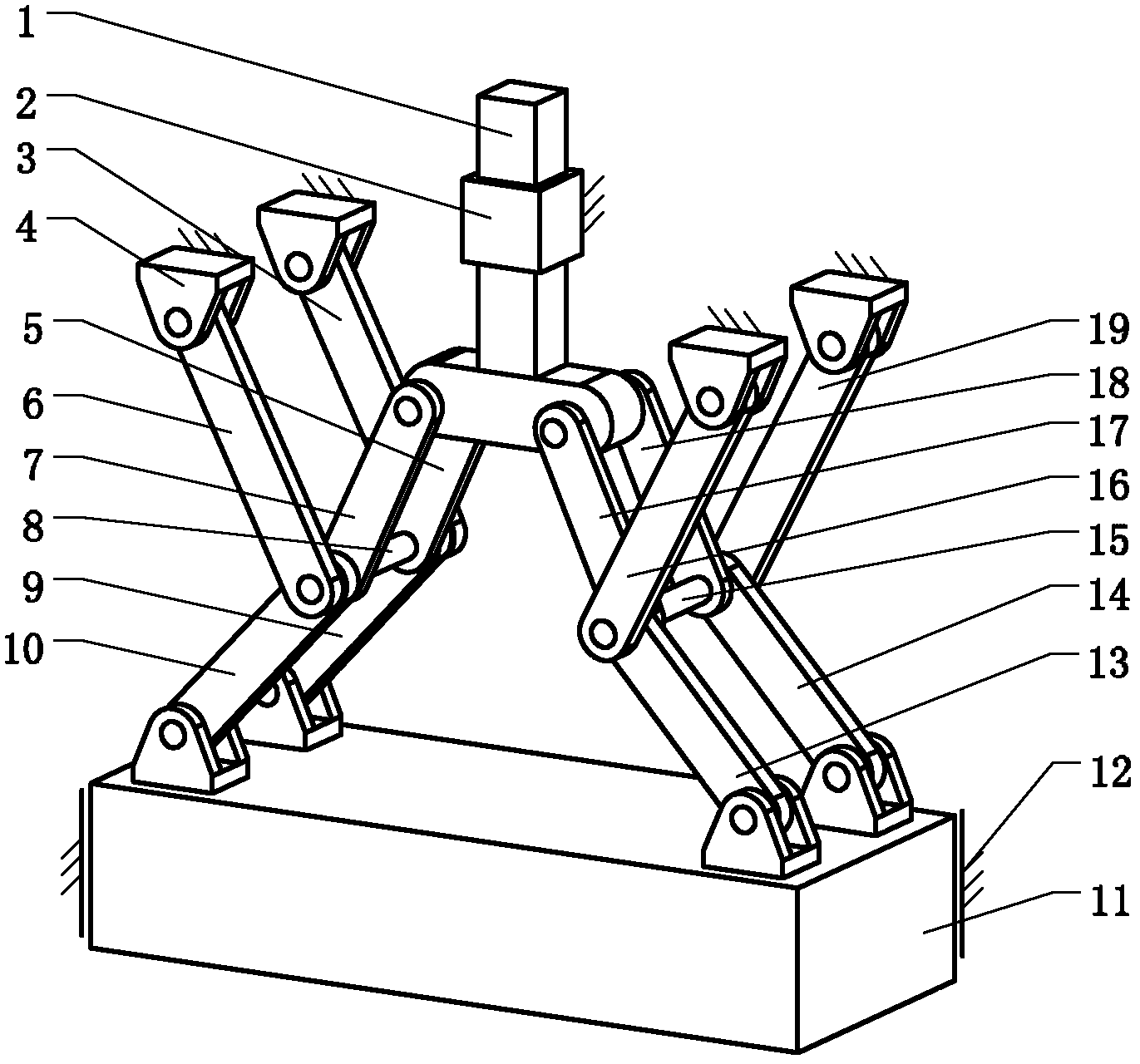

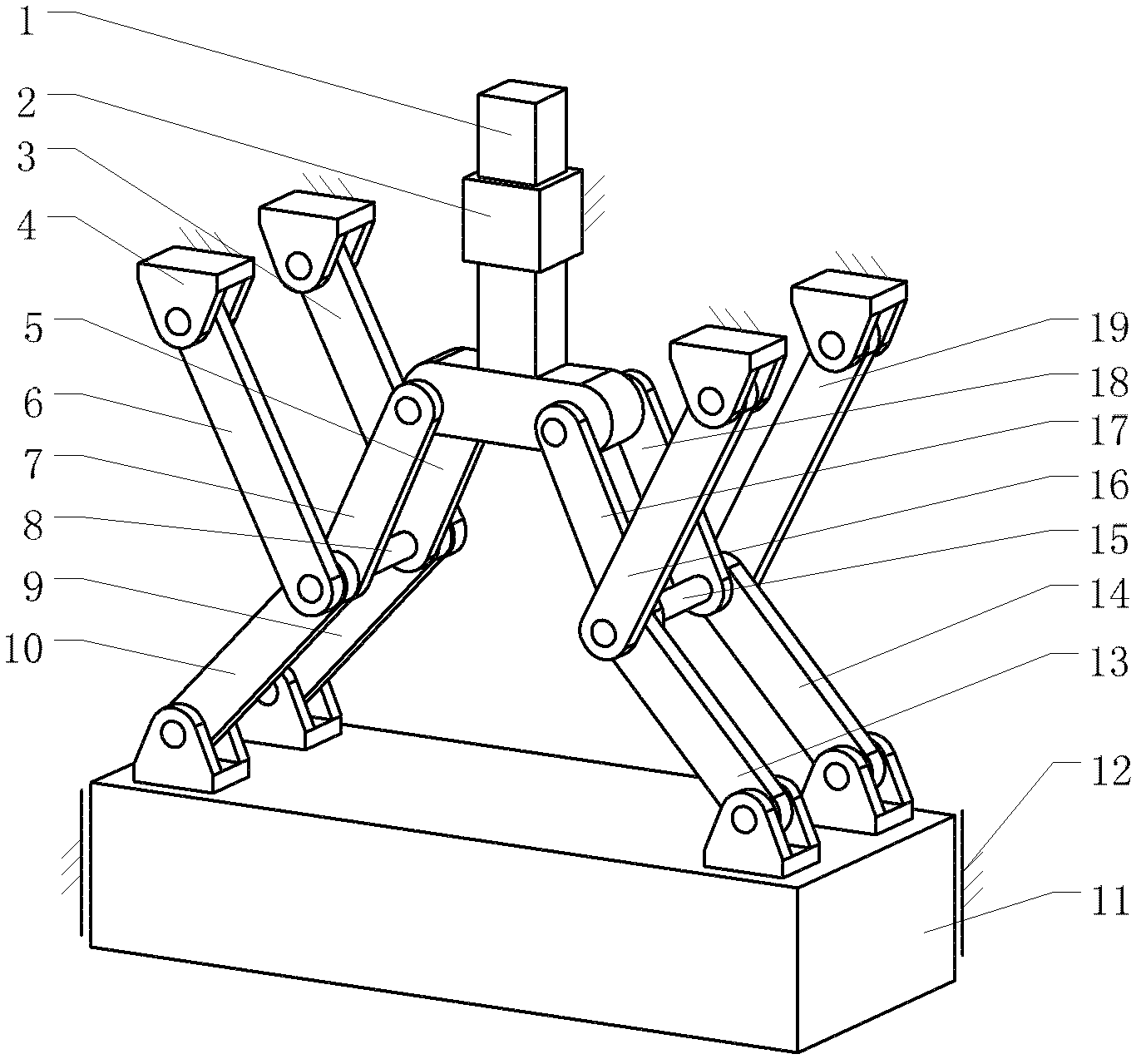

[0023] Such as figure 1 As shown, a booster device for a servo press includes: guide rod 1, guide rail 2, connecting rod A3, frame 4, connecting rod B5, connecting rod C6, connecting rod D7, connecting rod E8, connecting rod F9, connecting rod Rod G10, sliding platform 11, guide rail 12, connecting rod H13, connecting rod I14, connecting rod J15, connecting rod K16, connecting rod L17, connecting rod M18, connecting rod N19.

[0024] Such as figure 1 As shown, the first motion branch chain includes: connecting rod A3, connecting rod B5, and connecting rod F9, wherein: one end of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com