Combined elevator rail clamping device

A combined rail clamp technology, which is applied in elevators, transportation and packaging, etc., can solve the problems of fast wear of rail clamps, unstable control, and difficult deceleration regulation, and achieve reliable control, reliable performance, and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

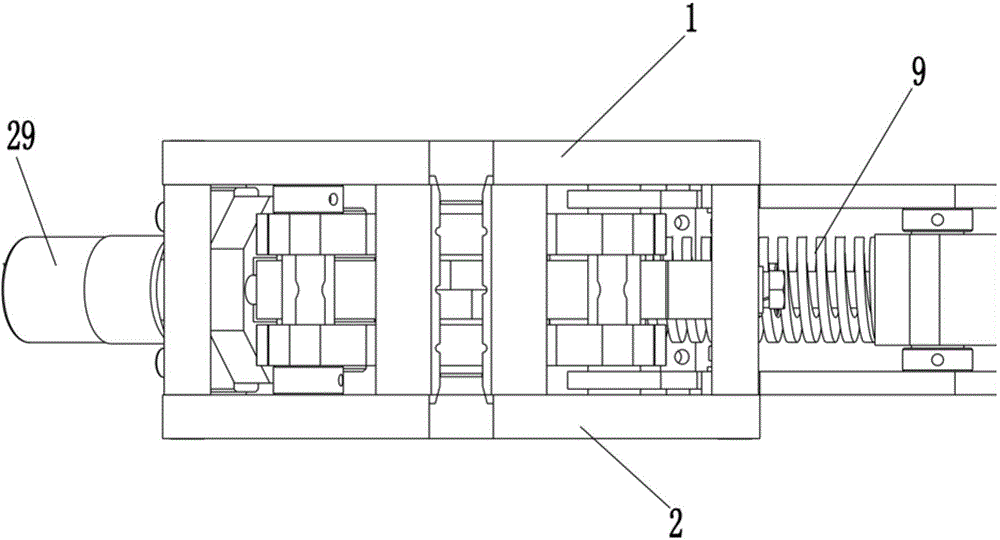

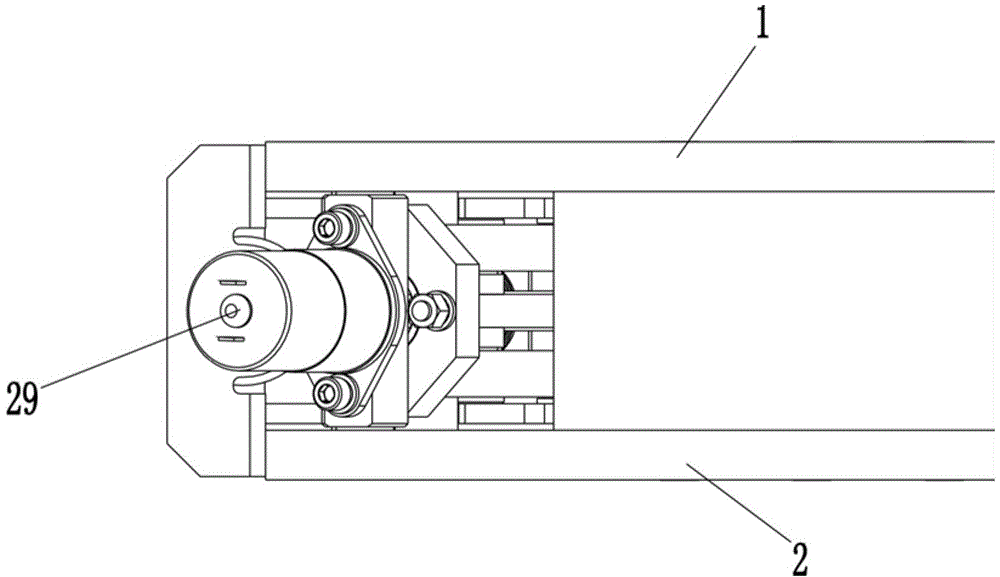

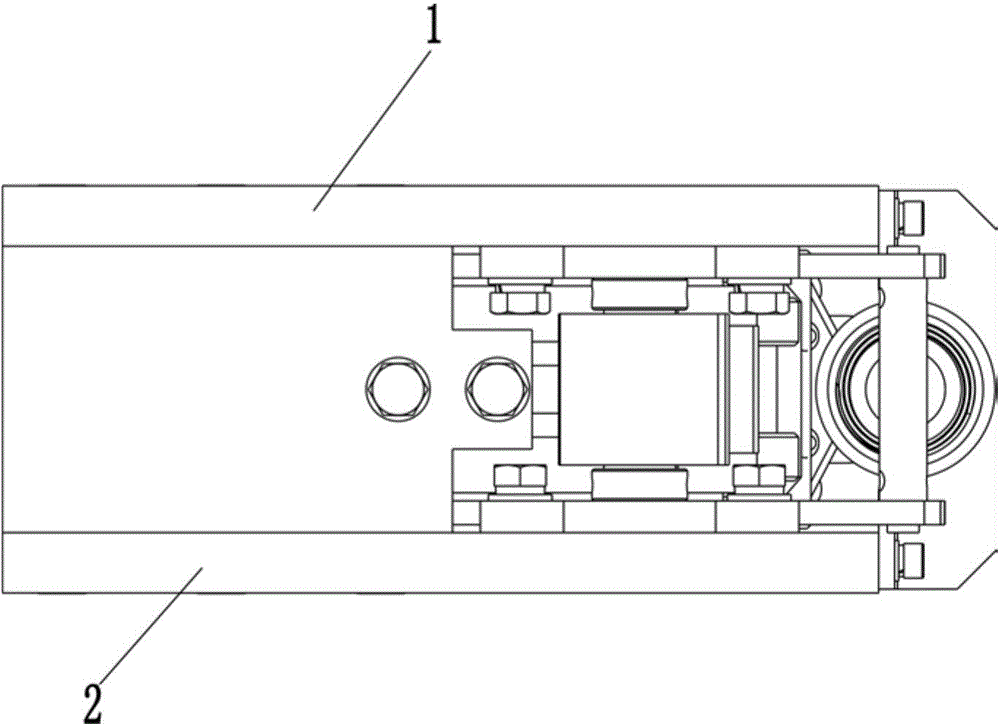

[0028] see Figure 1-9 , the structure of the top plate 1 is the same as that of the bottom plate 2, and the structure of the top plate 1 will be described in detail below.

[0029] The top plate 1 is square, and it is provided with a rectangular notch 1-1, a strip-shaped guide hole 1-2, a guide and positioning hole 1-3, and the rectangular notch 1-1 is located in the middle of one edge of the top plate 1, and the long strip The position of the guide hole 1-2 is close to the notch 1-1, and the centerlines of the two coincide and coincide with the centerline of the edge of the top plate 1. The guide and positioning hole 1-3 is near the other side opposite to the notch 1-1. The part of the guide and positioning hole 1-3 is arc-shaped, and one end of it is bent over an angle. Edges transition smoothly through curved edges.

[0030] The top plate 1 and the bottom plate 2 are arranged in parallel up and down, and the gaps, guide holes, guide and positioning holes between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com