A manual pressing device based on worm gear and crank connecting rod transmission

A technology of crank connecting rod and pressing device, applied in the field of machinery, can solve the problems such as the inability to maintain the clamping state of the clamp for a long time, the complex cost of equipment, environmental pollution, etc., to improve labor intensity, reduce energy consumption and achieve a high degree of greening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

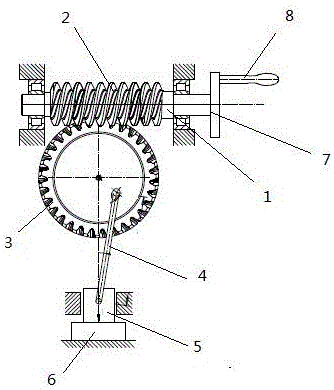

Embodiment 1

[0021] Such as figure 1 As shown, a manual pressing device based on worm gear and crank connecting rod transmission includes a rotating shaft 1 on which a worm 2 is fixed, and each worm 2 is provided with a Worm wheel 3, said worm wheel 3 is provided with crank connecting rod 4, the end of said crank connecting rod 4 is connected on the same pressure head 4, and one end of said rotating shaft 1 is fixedly connected with rotating disk 7, and said rotating disk 7 is provided with a handle 8, by manually turning the handle 8 in the forward direction, the rotating disk 7 connected to the handle 8 is driven, and the rotating disk 7 first transmits the power to the rotating shaft 1 and the worm 2, at this time, the mechanism performs the first force Then, the rotating worm 2 drives the worm gear 3 meshed with it to rotate, and at this time, the mechanism performs the second force amplification; the rotation of the worm gear 3 drives the crank connecting rod 4 hinged on it to swing, ...

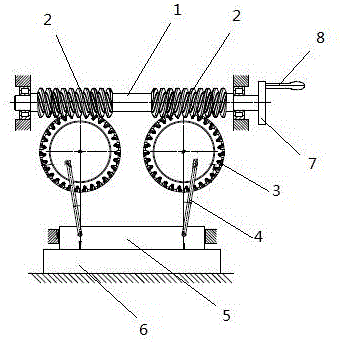

Embodiment 2

[0024] Such as figure 2 As shown, a manual pressing device based on worm gear and crank connecting rod transmission includes a rotating shaft 1 on which two worms 2 are fixed, and each worm 2 is provided with a The worm gear 3, the worm gear 3 is provided with a crank connecting rod 4, the end of the crank connecting rod 4 is connected to the same pressure head 4, one end of the rotating shaft 1 is fixedly connected with a rotating disk 7, the rotating The disc 7 is provided with a handle 8. By manually turning the handle 8 in the forward direction, the rotating disc 7 connected to the handle 8 is driven. The rotating disc 7 first transmits the power to the rotating shaft 1 and the worm 2. At this time, the mechanism performs the first force Then, the rotating worm 2 drives the left and right worm gears 3 meshed with it to rotate, and at this time, the mechanism performs a second force amplification; the left and right worm gears 3 rotate to drive the crank connecting rod 4 h...

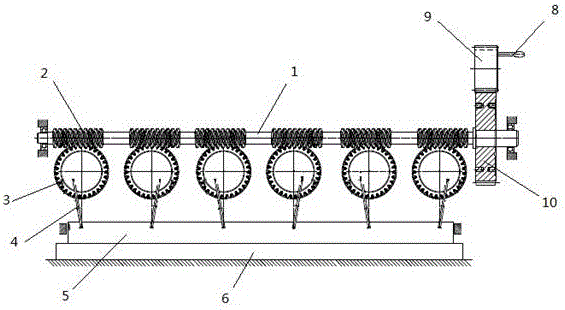

Embodiment 3

[0029] Such as image 3 As shown, a manual pressing device based on worm gear and crank connecting rod transmission includes a rotating shaft 1 on which six worms 2 are fixed, and each worm 2 is provided with a The worm gear 3 is provided with a crank connecting rod 4 on the worm gear 3, and the ends of the crank connecting rod 4 are connected to the same pressing plate 5, and a driven gear 10 is fixedly connected to one end of the rotating shaft 1. The driving gear 10 is provided with a driving gear 9 meshing with it, and the driving gear 9 is provided with a handle 8, and the hand rotates the handle 8 forward, driving the driving gear 9 hinged with the handle 8 to rotate forward, and the driving gear 9 passes through the gear The meshing first transmits the power to the driven gear 10 and the worm 1. At this time, the mechanism amplifies the force for the first time; then, the rotating worm 1 drives the six worm gears 2 meshed with it to rotate, and the mechanism performs a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com