Traveling type automatic material loading patching machine device

An automatic feeding and spraying machine technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of small loading hopper capacity, difficulty in coordination, and affecting construction safety, etc., and achieve reduction in stroke, cylinder diameter and Stroke optimization, the effect of solving the contradiction between thrust and stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

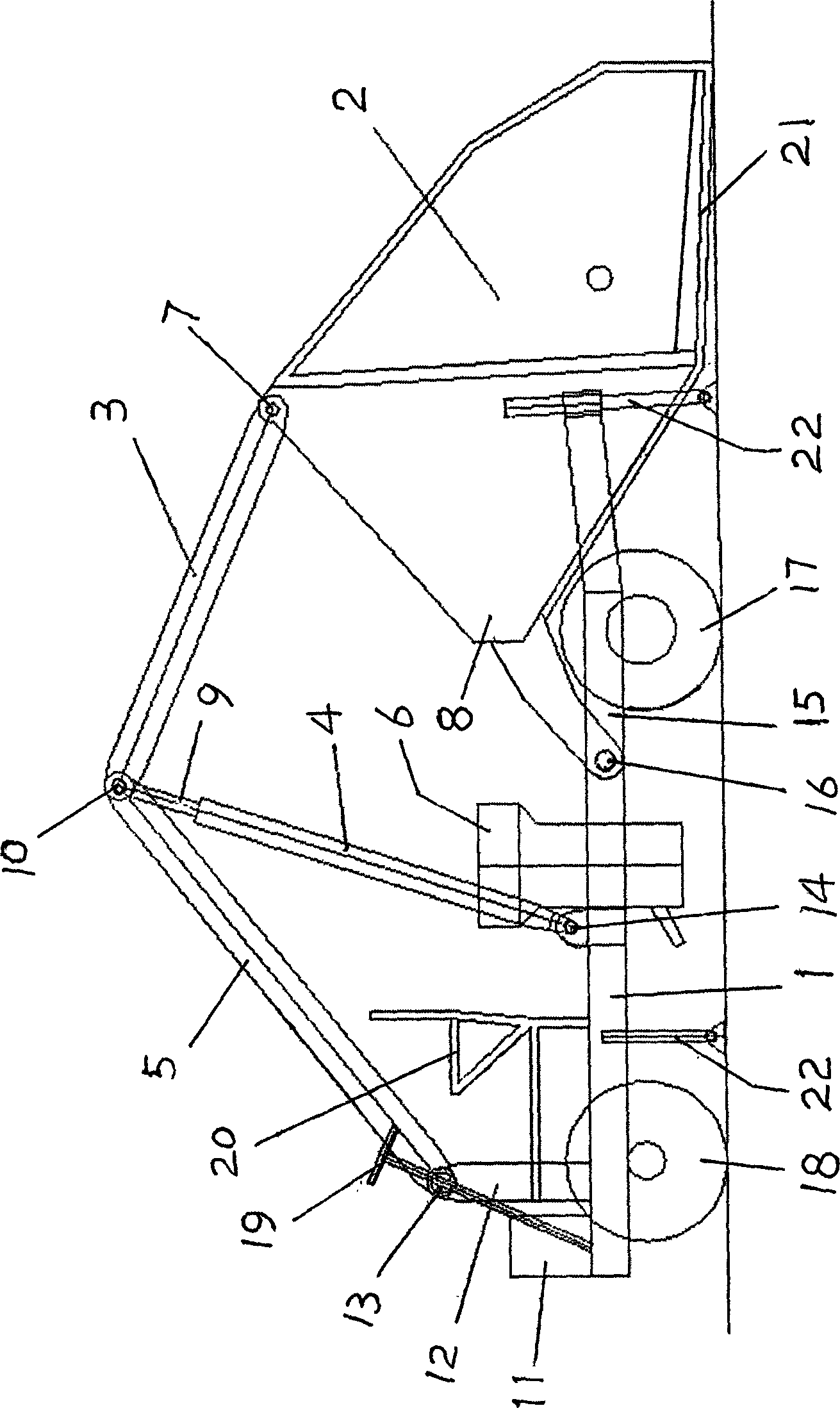

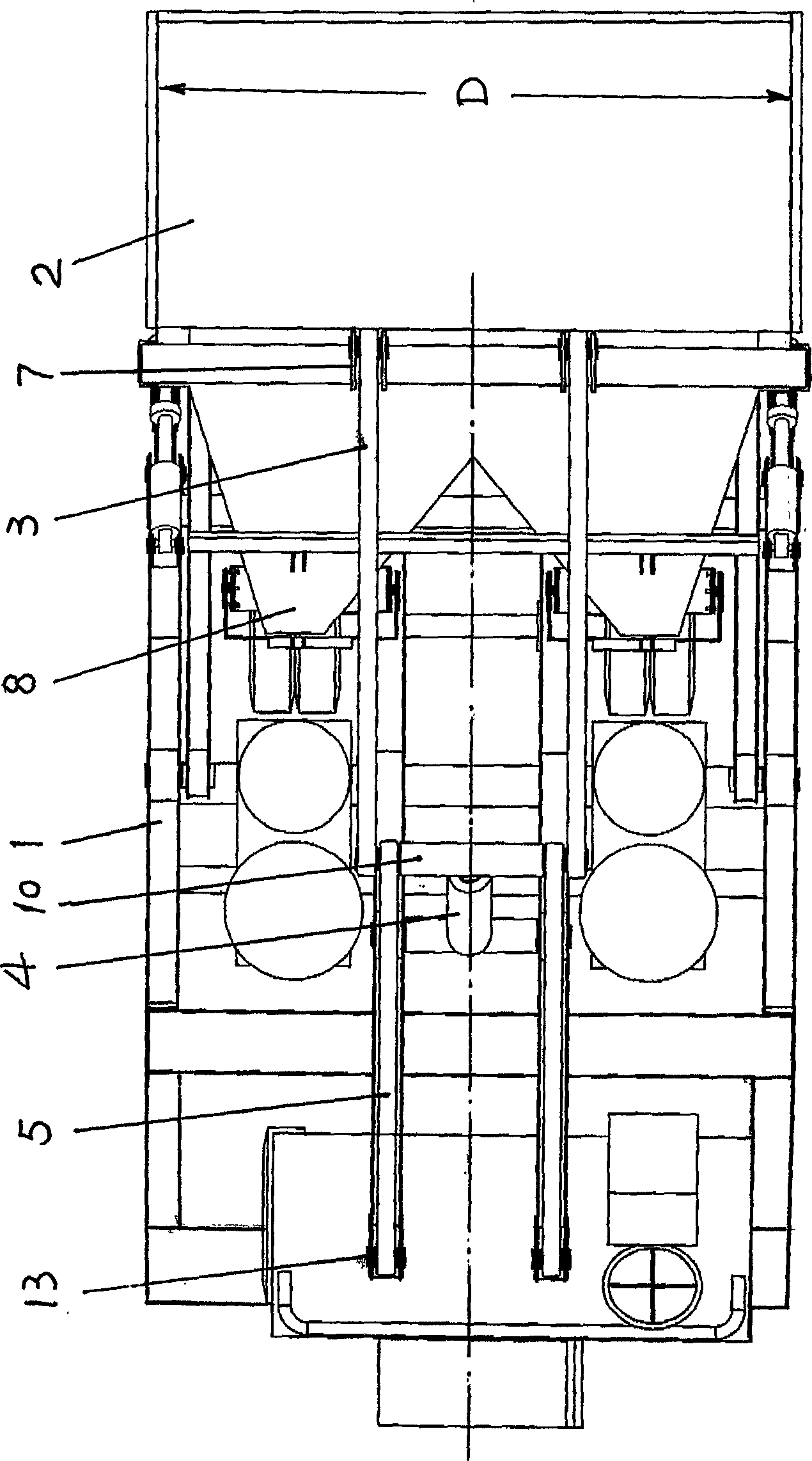

[0018] With reference to the accompanying drawings, it can be seen that the specific parts of this walking type automatic feeding spraying machine device of the present invention include: 1 ~ car body frame, 2 ~ loading hopper, 3 ~ pull rod (corresponding to the hinge point 7 above the loading hopper) Hinged), 4 ~ hydraulic cylinder (only one or two can be installed), 5 ~ connecting rod (hinged with the hinge point near the head of the car body), 6 ~ spraying machine, 7 ~ above the loading hopper Hinge point (hinged with one end of the pull rod), 8~the discharge end of the hopper, 9~the push rod of the hydraulic cylinder (hinged with the hinge point 10 of the pull rod and the connecting rod), 10~the hinge point of the tie rod and the connecting rod , 11 ~ the power transmission mechanism driving the car body (forming the driving system), 12 ~ the head of the car body, 13 ~ the hinge point at the head of the car body, 14 ~ the hinge point at the middle of the car body (located b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com